| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Overview

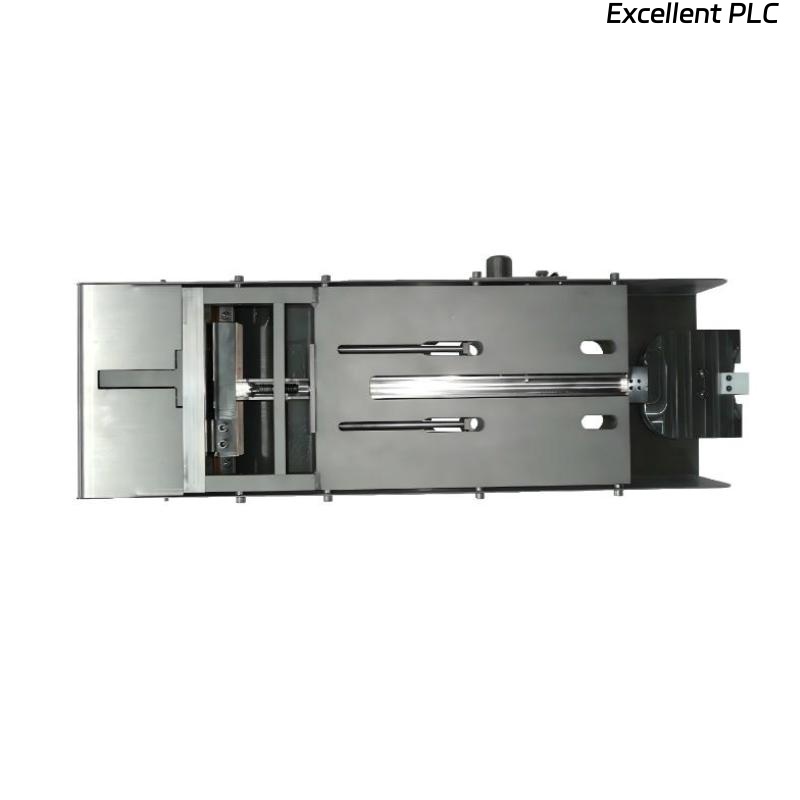

The Epro PR6480/0A1-001 is a highly precise eddy current sensor designed for non-contact displacement, proximity, and position measurement. This sensor leverages eddy current technology to offer accurate detection of the distance between the sensor and the target material without requiring physical contact. The PR6480/0A1-001 is widely used in various industries for applications such as machinery health monitoring, vibration detection, and position measurement.

Built for reliable performance in demanding environments, this sensor is temperature-resistant and works in high-vibration and electromagnetic interference environments. The PR6480/0A1-001 is commonly used in industries like automotive, aerospace, power generation, and manufacturing, where precision and durability are critical. It offers versatile configurations for both small and large-scale operations, with optional sensor head diameters to match specific application needs.

Product Parameters

Here are the technical parameters for the Epro PR6480/0A1-001 Eddy Current Sensor:

| Parameter | Specification |

|---|---|

| Model | PR6480/0A1-001 |

| Sensor Head Diameter | Optional (specific model dependent) |

| Output Type | Analog (typically 4-20 mA or 0-10V) |

| Measurement Range | Customizable based on application |

| Operating Temperature | -40°C to +100°C |

| Material | Stainless Steel |

| Mounting Type | Fixed mounting |

| Power Supply | 24V DC (Nominal) |

| Accuracy | ±0.01% of full scale |

| Measurement Principle | Eddy Current |

| Cable Length | Optional |

Product Applications

The Epro PR6480/0A1-001 is suitable for a wide range of industrial applications where high-precision measurements are required. Some of the most common uses include:

-

Vibration Monitoring: Detects small vibrations and movements in rotating machinery such as motors, turbines, and compressors, enabling early fault detection.

-

Position and Displacement Measurement: Ideal for precise linear displacement and angular position measurements in manufacturing and automation systems.

-

Condition Monitoring: Used to monitor mechanical components like gears, bearings, and shafts to help predict failures and optimize maintenance schedules.

-

Automated Systems: Provides position feedback for robotics, material handling systems, and conveyor systems.

-

Material Thickness Measurement: Monitors the thickness of materials during production processes, particularly metals and composites.

-

Speed Monitoring: Detects the speed of rotating parts in machinery to ensure proper functioning.

Product Advantages

-

High Measurement Precision: The PR6480/0A1-001 offers exceptional ±0.01% accuracy of full scale, making it ideal for high-precision displacement, proximity, and position measurements.

-

Non-contact Technology: The eddy current technology ensures that measurements are taken without physical contact, preventing wear on the sensor and target, leading to a longer operational life.

-

Durability: Constructed from stainless steel, the sensor can withstand harsh environments, including high temperatures, vibrations, and exposure to electromagnetic interference.

-

Wide Temperature Range: The sensor operates effectively across a broad temperature range from -40°C to +100°C, making it suitable for a variety of industrial environments.

-

Customizable Measurement Range: The PR6480/0A1-001 sensor can be customized for different measurement ranges, making it versatile and adaptable to diverse industrial needs.

-

Easy Integration: With its analog output (4-20 mA or 0-10V), the sensor can be easily integrated into existing control and monitoring systems, enabling real-time feedback for efficient process control.

FAQ

1. What is the measurement principle of the Epro PR6480/0A1-001 sensor?

The Epro PR6480/0A1-001 uses eddy current technology, which employs electromagnetic fields to detect changes in distance between the sensor and the target without physical contact.

2. What is the output type of the Epro PR6480/0A1-001 sensor?

The sensor provides an analog output, typically 4-20 mA or 0-10V, which is widely compatible with most industrial systems.

3. What industries benefit from using the Epro PR6480/0A1-001 sensor?

Industries such as automotive, aerospace, manufacturing, and power generation benefit from the precision and reliability of the Epro PR6480/0A1-001 sensor.

4. How accurate is the Epro PR6480/0A1-001 sensor?

The sensor offers a high accuracy of ±0.01% of full scale, making it suitable for high-precision applications requiring reliable and consistent measurements.

5. What is the temperature range for the Epro PR6480/0A1-001 sensor?

The sensor operates in environments ranging from -40°C to +100°C, making it adaptable to a wide range of industrial settings, including extreme temperatures.

6. Can the Epro PR6480/0A1-001 sensor be used for vibration monitoring?

Yes, the PR6480/0A1-001 sensor is highly effective for detecting small vibrations in rotating equipment such as motors, compressors, and turbines.

7. How does the Epro PR6480/0A1-001 sensor integrate into existing systems?

The PR6480/0A1-001 offers analog output (4-20 mA or 0-10V), which allows easy integration into most control and monitoring systems for real-time feedback.

8. What materials is the Epro PR6480/0A1-001 sensor made from?

The sensor is constructed from stainless steel, providing durability and resistance to corrosion, even in harsh industrial environments.

9. Can the Epro PR6480/0A1-001 sensor be used for condition monitoring?

Yes, the sensor is ideal for condition monitoring, providing real-time data on mechanical components like bearings and shafts to predict failures and optimize maintenance.

10. What is the main advantage of non-contact measurement with the Epro PR6480/0A1-001 sensor?

The non-contact measurement eliminates wear on both the sensor and target, ensuring a longer lifespan and greater reliability in harsh environments.

Recommended Similar Models

| Model | Description |

|---|---|

| PR6480/091-100 | High-precision eddy current sensor for larger measurement ranges |

| PR6440/100 | Eddy current sensor suitable for high-speed applications |

| PR6470/081-200 | Digital output version for improved signal processing capabilities |

| PR6500/150 | Long-range eddy current sensor with higher environmental resistance |

| PR6600/100 | Sensor designed for material thickness measurements in harsh conditions |

| PR6200/200 | Compact sensor with flexible output options for precise measurement |

Popular Models from Epro

| Model | Description |

|---|---|

| PR6420/150 | High-performance sensor for harsh environments and dynamic applications |

| PR6150/100 | Vibration sensor with advanced signal conditioning features |

| PR6300/150 | High-accuracy displacement sensor for precision equipment |

| PR6400/200 | Non-contact position sensor for automated systems |

| PR6150/200 | Ideal for condition monitoring and predictive maintenance |

| PR6600/100 | Provides real-time feedback for automated process control |

Excellent PLC

Excellent PLC