| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

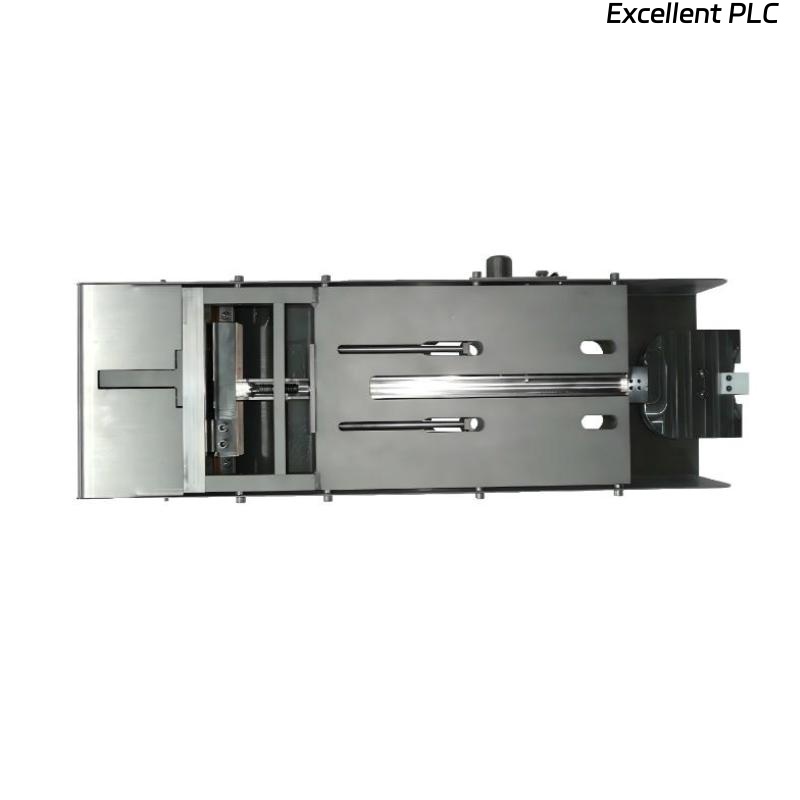

Product Overview

The Epro PR6480/0B1-100 is a high-performance eddy current sensor that provides highly accurate, non-contact measurements of displacement, position, and proximity. Using eddy current technology, this sensor detects the distance between the sensor and the target object by measuring the changes in the magnetic field, allowing precise monitoring without physical contact.

This sensor is particularly well-suited for industrial monitoring applications, where the precise measurement of dynamic or stationary parts is essential. The PR6480/0B1-100 is widely used across industries such as automotive, aerospace, power generation, and manufacturing, enabling predictive maintenance, vibration monitoring, and position control.

The PR6480/0B1-100 sensor offers customization options with an optional sensor head diameter, making it flexible for specific applications and a wide range of measurement requirements.

Product Parameters

Here are the key technical specifications for the Epro PR6480/0B1-100 Eddy Current Sensor:

| Parameter | Specification |

|---|---|

| Model | PR6480/0B1-100 |

| Sensor Head Diameter | Optional (specific model dependent) |

| Output Type | Analog (typically 4-20 mA or 0-10V) |

| Measurement Range | Customizable based on application |

| Operating Temperature | -40°C to +100°C |

| Material | Stainless Steel |

| Mounting Type | Fixed mounting |

| Power Supply | 24V DC (Nominal) |

| Accuracy | ±0.01% of full scale |

| Measurement Principle | Eddy Current |

| Cable Length | Optional |

Product Applications

The Epro PR6480/0B1-100 is a versatile sensor suitable for a range of precision measurement applications. Some of the common uses include:

-

Vibration Monitoring: The sensor is used in machinery health monitoring, detecting small vibrations in rotating parts such as motors, turbines, and pumps to prevent unplanned downtime and ensure machine reliability.

-

Position and Displacement Measurement: Ideal for precise position feedback in automated systems, robotics, and material handling systems. This sensor provides critical data to ensure accuracy in positioning and movement.

-

Condition Monitoring: Used to assess the condition of mechanical components like gears, bearings, and shafts, allowing for timely maintenance actions and minimizing the risk of system failure.

-

Speed Monitoring: The sensor measures rotational speed in machines such as turbines and motors, ensuring systems operate at optimal speeds and preventing damage caused by speed variations.

-

Material Thickness Measurement: For quality control purposes, this sensor can measure the thickness of materials such as metals, composites, and plastics during production processes.

-

Automated Systems Feedback: Provides reliable position feedback for automated systems that require precise control of parts, making it ideal for manufacturing environments and robotics applications.

Product Advantages

-

Non-contact Measurement: The eddy current technology ensures that there is no direct contact between the sensor and the target, thus eliminating wear and ensuring consistent, reliable performance over time.

-

High Precision: With an accuracy of ±0.01% of full scale, the PR6480/0B1-100 delivers precise measurements, which are critical for high-end industrial applications where small deviations can lead to significant issues.

-

Durability: Constructed from stainless steel, the sensor is built to withstand harsh conditions, including high temperatures, vibrations, and exposure to electromagnetic interference (EMI).

-

Wide Operating Temperature Range: The sensor operates in environments with temperatures ranging from -40°C to +100°C, allowing it to function in a variety of challenging industrial environments.

-

Customizable Features: The sensor head diameter is customizable, enabling the PR6480/0B1-100 to be tailored to meet specific measurement needs, providing flexibility for a wide range of applications.

-

Seamless Integration: With analog outputs like 4-20 mA or 0-10V, this sensor can be easily integrated into control and monitoring systems, providing real-time feedback for process optimization and automated control.

FAQ

1. What is the measurement principle of the Epro PR6480/0B1-100 sensor?

The Epro PR6480/0B1-100 utilizes eddy current technology to measure the displacement or position of a target by detecting changes in the electromagnetic field without physical contact.

2. What output types are available for the Epro PR6480/0B1-100 sensor?

The sensor typically provides analog outputs, such as 4-20 mA or 0-10V, making it compatible with most industrial control and monitoring systems.

3. Can the Epro PR6480/0B1-100 sensor be used in vibration monitoring applications?

Yes, the sensor is widely used in vibration monitoring, enabling the detection of vibrations in rotating machinery such as turbines, motors, and pumps.

4. What industries can benefit from using the Epro PR6480/0B1-100 sensor?

The PR6480/0B1-100 is highly beneficial in industries such as automotive, aerospace, manufacturing, and power generation, where precise measurements of displacement, position, and proximity are required.

5. What is the temperature range in which the Epro PR6480/0B1-100 sensor can operate?

The Epro PR6480/0B1-100 sensor is designed to operate within a temperature range of -40°C to +100°C, making it suitable for use in both cold and hot industrial environments.

6. Can the Epro PR6480/0B1-100 sensor be customized for specific applications?

Yes, the sensor offers customizable sensor head diameters and measurement ranges to suit the specific needs of different industrial applications.

7. How does the Epro PR6480/0B1-100 sensor help in predictive maintenance?

The PR6480/0B1-100 provides real-time data on displacement, vibration, and position, enabling early detection of potential issues in rotating machinery and helping avoid costly downtime.

8. What are the main benefits of using a non-contact sensor like the Epro PR6480/0B1-100?

Non-contact sensors, like the PR6480/0B1-100, prevent wear and tear on both the sensor and target, leading to increased sensor lifespan and more reliable performance.

9. How does the sensor integrate with existing control systems?

The PR6480/0B1-100 sensor provides analog outputs, which can be easily connected to existing control and monitoring systems for real-time feedback and system integration.

10. Is the Epro PR6480/0B1-100 sensor suitable for automated systems?

Yes, the sensor is ideal for providing position feedback in automated systems, robotics, and manufacturing environments, where high precision and reliability are critical.

Recommended Similar Models

| Model | Description |

|---|---|

| PR6480/091-100 | High-precision eddy current sensor for larger measurement ranges |

| PR6440/100 | Eddy current sensor suitable for high-speed applications |

| PR6470/081-200 | Digital output version for improved signal processing capabilities |

| PR6500/150 | Long-range eddy current sensor with higher environmental resistance |

| PR6600/100 | Sensor designed for material thickness measurements in harsh conditions |

| PR6200/200 | Compact sensor with flexible output options for precise measurement |

Popular Models from Epro

| Model | Description |

|---|---|

| PR6420/150 | High-performance sensor for harsh environments and dynamic applications |

| PR6150/100 | Vibration sensor with advanced signal conditioning features |

| PR6300/150 | High-accuracy displacement sensor for precision equipment |

| PR6400/200 | Non-contact position sensor for automated systems |

| PR6150/200 | Ideal for condition monitoring and predictive maintenance |

| PR6600/100 | Provides real-time feedback for automated process control |

Excellent PLC

Excellent PLC