| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Overview

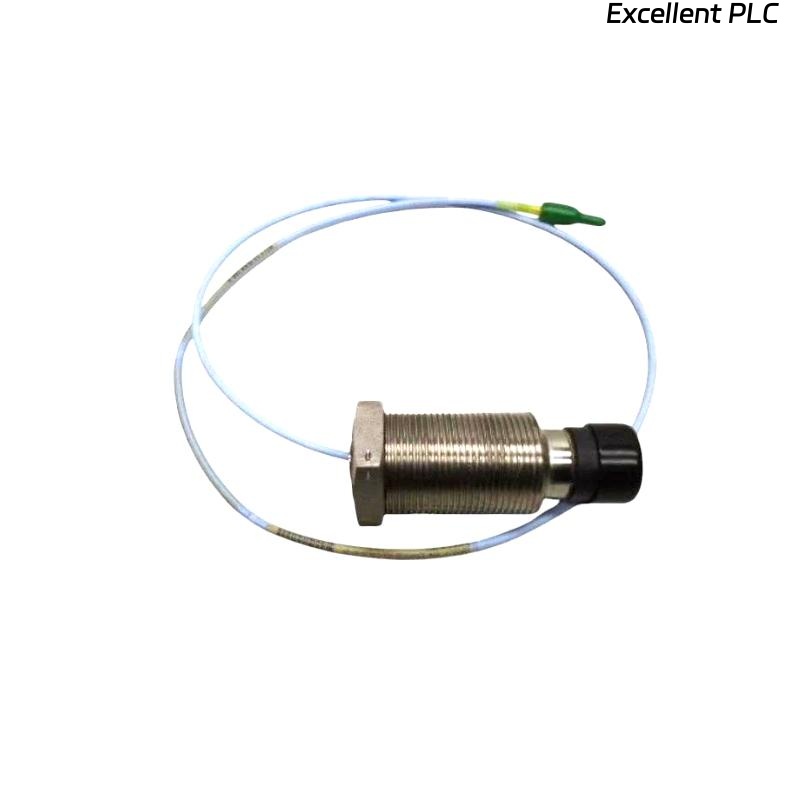

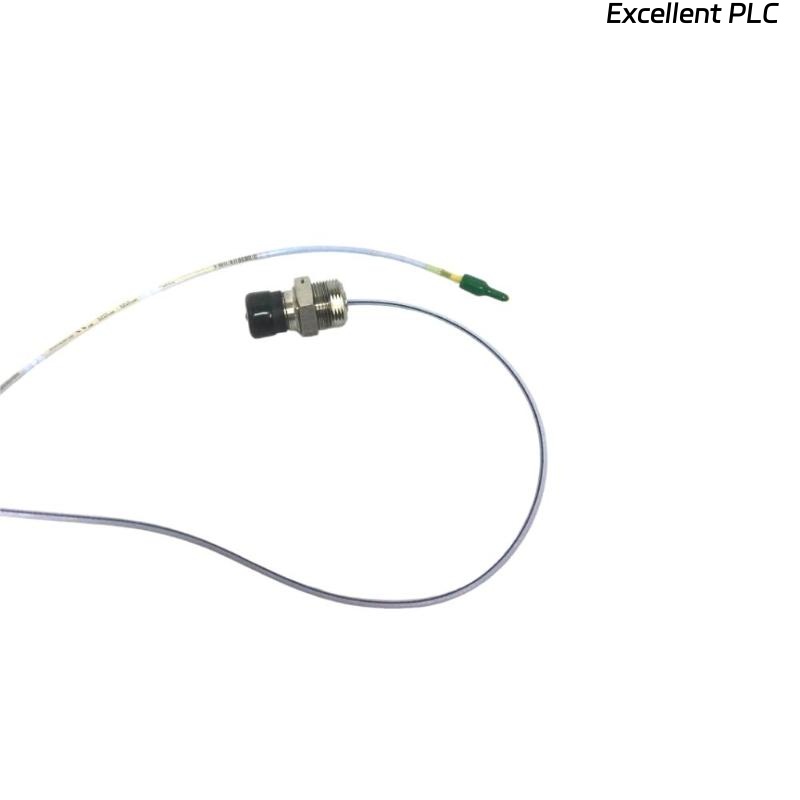

The Bently Nevada 330851-02-000-080-10-00-05 3300 XL 25 mm proximity probe is part of the renowned 3300 XL series, designed for accurate and reliable shaft displacement and vibration measurements in industrial machinery. This model uses eddy current technology, which allows it to measure without direct contact, thus minimizing wear and extending the life of both the sensor and the machinery being monitored.

The 3300 XL series is highly valued in industries where precision monitoring is essential, such as in power generation, oil & gas, and chemical processing. The 25 mm measurement range makes this probe ideal for larger machinery that requires precise and accurate readings to detect issues like misalignment, imbalance, and bearing wear.

With a total length of 1.0 meter and a weight of 0.23 kg, this probe is designed to be flexible and adaptable to various industrial environments, ensuring long-term, reliable operation under challenging conditions.

Product Parameters

Here are the key technical specifications of the Bently Nevada 330851-02-000-080-10-00-05 proximity probe:

| Parameter | Specification |

|---|---|

| Model | 330851-02-000-080-10-00-05 |

| Measurement Range | 25 mm |

| Output Type | Analog (4-20 mA or 0-10V) |

| Measurement Principle | Eddy Current |

| Probe Length | 1.0 meter |

| Weight | 0.23 kg |

| Operating Temperature | -40°C to +85°C |

| Material | Stainless Steel |

| Mounting Type | Fixed Mounting |

| Power Supply | 24V DC (Nominal) |

| Accuracy | ±0.01% of full scale |

Product Applications

The Bently Nevada 3300 XL 25 mm proximity probe is designed for use in industries that require highly accurate measurements of rotating machinery, such as:

-

Power Generation: The probe is used in the monitoring of turbines, generators, and other rotating machinery to detect early signs of wear or misalignment.

-

Oil and Gas: Used to monitor compressors, pumps, and turbines in oil rigs and refineries, ensuring that machinery is running smoothly and efficiently.

-

Chemical Processing: Essential for monitoring rotating equipment in chemical plants, where maintaining operational reliability is crucial for safety and efficiency.

-

Mining: Ideal for large-scale mining operations, where machinery is subjected to heavy loads and harsh environmental conditions.

-

Aerospace and Manufacturing: Provides accurate monitoring of aircraft engines, manufacturing equipment, and heavy-duty machinery, ensuring reliability and performance.

-

Marine Applications: Used for condition-based monitoring of ship turbines, pumps, and other critical systems, helping avoid unexpected downtime or failures.

Product Advantages

-

Non-contact Measurement: The eddy current technology allows for non-contact measurement, which helps reduce the wear and tear on both the sensor and the machinery.

-

High Accuracy: The probe provides highly accurate measurements with ±0.01% accuracy, making it suitable for precision applications.

-

Durable and Resistant: Built with stainless steel, the probe is resistant to corrosion, vibrations, and electromagnetic interference, ensuring it operates reliably in tough environments.

-

Flexible Installation: The 1.0-meter cable length offers flexibility in installation, making it easy to integrate into a wide range of monitoring systems.

-

Wide Operating Temperature Range: The probe can function effectively in temperatures ranging from -40°C to +85°C, making it suitable for various industrial conditions.

-

Advanced Monitoring Capability: Compatible with 4-20 mA and 0-10V outputs, the probe integrates seamlessly into most monitoring systems, allowing for real-time data analysis.

FAQ

1. What is the purpose of the Bently Nevada 3300 XL 25 mm proximity probe?

The probe is used for precise monitoring of shaft displacement and vibration in rotating machinery, enabling early detection of faults like misalignment, imbalance, and bearing wear.

2. How does the Bently Nevada 3300 XL proximity probe work?

It uses eddy current technology to measure displacement without contact, generating an electromagnetic field that detects changes in distance between the probe and the machine surface.

3. What industries benefit from using this proximity probe?

Industries like power generation, oil & gas, chemical processing, mining, and aerospace rely on the probe for accurate condition monitoring of critical rotating machinery.

4. How accurate is the Bently Nevada 3300 XL proximity probe?

The probe offers an accuracy of ±0.01% of the full scale, ensuring reliable and precise measurements for high-performance machinery.

5. What are the typical applications for this proximity probe?

It is used for monitoring turbines, compressors, motors, and other large machinery components, detecting potential issues like misalignment, vibration, and wear.

6. Can the probe operate in extreme environmental conditions?

Yes, the 3300 XL 25 mm proximity probe is designed to function in extreme conditions, with an operating temperature range of -40°C to +85°C, making it adaptable to various industrial environments.

7. What is the significance of non-contact measurement with this probe?

Non-contact measurement minimizes wear on both the sensor and machinery, increasing the longevity and reliability of both the probe and the equipment being monitored.

8. How does the Bently Nevada 3300 XL proximity probe integrate with other systems?

The probe provides 4-20 mA or 0-10V analog outputs, making it compatible with most industrial monitoring systems for real-time condition-based monitoring.

9. Is the 3300 XL probe suitable for predictive maintenance applications?

Yes, the probe is a key component of predictive maintenance systems, enabling early detection of equipment issues and preventing costly downtime or failures.

10. What is the probe’s lifespan in industrial applications?

The 3300 XL 25 mm proximity probe is designed for long-term durability, with its stainless steel construction offering resistance to corrosion and mechanical wear in harsh environments.

Recommended Similar Models

| Model | Description |

|---|---|

| 330704-000-070-50-02-00 | 3300 XL 8 mm proximity probe for medium-range applications |

| 330704-000-060-50-02-00 | 3300 XL 8 mm proximity probe with higher sensitivity |

| 330850-00-000-070-10-00 | 3300 XL 12 mm proximity probe for larger machinery monitoring |

| 330854-00-000-070-10-00 | 3300 XL proximity probe with enhanced durability for extreme environments |

| 330301-00-000-070-10-00 | 3300 XL 25 mm proximity probe for heavy-duty industrial use |

| 330107-00-000-070-10-00 | 3300 XL proximity probe for precision measurement in rotating machinery |

Popular Models from Bently Nevada

| Model | Description |

|---|---|

| 330101-02-21-10-01-00 | 3300 XL 8 mm proximity probe for compact systems |

| 330104-09-16-05-01-05 | 3300 XL 5 mm proximity probe for high-precision applications |

| 330171-00-36-05-02-05 | 3300 XL 5 mm proximity probe with advanced vibration measurement |

| 330301-00-000-070-10-01 | 3300 XL 10 mm proximity probe for condition monitoring |

| 330171-00-20-10-02-05 | 3300 XL 5 mm proximity probe for heavy-duty industrial machinery |

| 330704-000-070-50-02-00 | 3300 XL 8 mm proximity probe for large-scale machinery monitoring |

Excellent PLC

Excellent PLC