| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

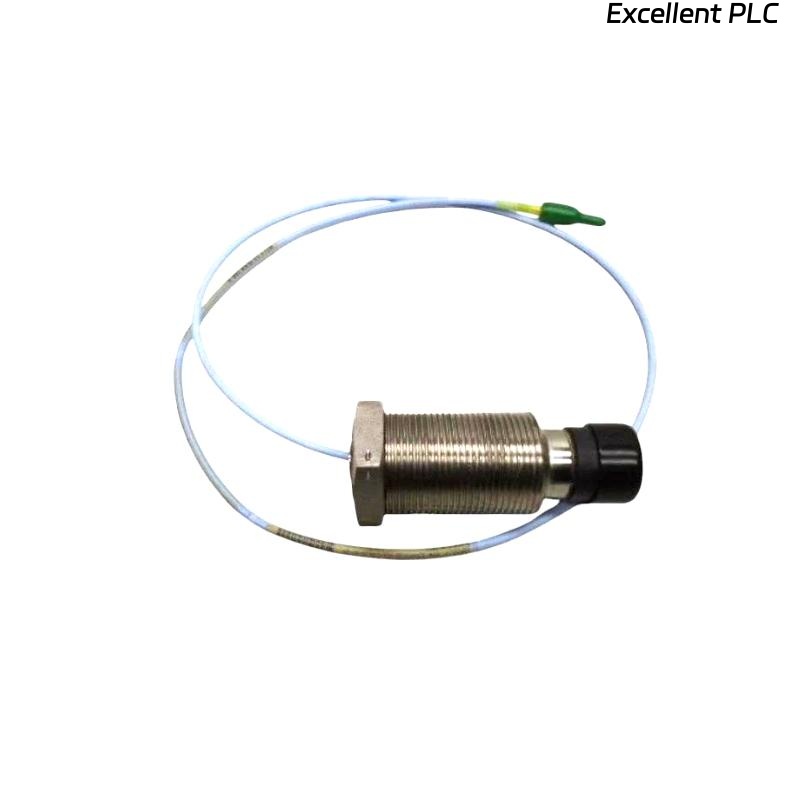

The Bently Nevada 330851-04-000-015-10-01-05 is a highly reliable 25mm proximity probe designed for precise measurement in rotating machinery applications. This probe is part of the 3300 XL series, known for its exceptional accuracy, durability, and ease of use. It is an essential component in vibration monitoring systems, used extensively in industrial applications to ensure the safety and efficiency of machinery.

The 3300 XL series features an advanced sensor that can be paired with various monitoring systems to detect any misalignment, imbalance, or mechanical fault in rotating equipment. This proximity probe is primarily used for rotating equipment condition monitoring, providing critical data to maintain operational integrity and reduce the risk of failures.

Product Specifications

| Specification | Value |

|---|---|

| Model | Bently Nevada 330851-04-000-015-10-01-05 |

| Probe Type | Proximity Probe (25 mm) |

| Probe Size | 25 mm diameter |

| Total Length | 1.0 meter |

| Weight | 0.33 kg |

| Material | Stainless Steel |

| Temperature Range | -40°C to +120°C |

| Mounting Type | Surface Mount |

| Signal Type | 4-20mA Output |

| Operating Voltage | 10-30 VDC |

| Measurement Range | 0-25 mm |

| Accuracy | ±0.05 mm |

Applications

The 3300 XL 25mm Proximity Probe is suitable for a wide range of industrial applications, including:

-

Vibration Monitoring: It helps detect vibration levels in rotating machinery like motors, pumps, compressors, and turbines.

-

Condition Monitoring: Essential for monitoring bearing wear, shaft alignment, and machinery imbalance.

-

Predictive Maintenance: It provides real-time data that supports maintenance decisions, helping avoid unnecessary downtime and reduce repair costs.

-

Machinery Protection: Used in systems designed to prevent machinery damage by monitoring key parameters, ensuring operations run smoothly.

-

Rotating Equipment Monitoring: Specifically for large-scale industrial operations, it can detect faults such as misalignment and imbalance in rotating equipment.

-

Process Industries: Widely used in industries like power generation, oil & gas, and manufacturing where high-performance equipment requires constant monitoring.

Advantages

-

High Accuracy: With an accuracy of ±0.05 mm, this probe ensures precise measurement for sensitive equipment.

-

Wide Temperature Range: Designed to perform in temperatures ranging from -40°C to +120°C, making it suitable for harsh environments.

-

Durability: Stainless steel construction ensures long-term durability even under challenging conditions.

-

Compatibility: Easily integrates with the Bently Nevada 3300 XL system, ensuring seamless operation with other monitoring components.

-

Signal Output: Provides a 4-20 mA output for easy integration with monitoring systems and data collection.

-

Predictive Maintenance: By providing real-time data on machinery health, it contributes to reducing unplanned downtime and improving operational efficiency.

-

Versatility: Ideal for use in various industries like oil & gas, power plants, and industrial manufacturing.

FAQ

1. What is the working principle of the 3300 XL proximity probe?

The 3300 XL proximity probe works on the principle of inductance, where the probe measures the change in magnetic field as it gets closer to a metal object (such as a shaft). This change is then converted into a corresponding electrical signal.

2. Can the 3300 XL proximity probe be used in hazardous environments?

Yes, the 3300 XL proximity probe is designed to be used in a variety of environments, including hazardous zones, provided it is used in accordance with the safety guidelines for installation in those areas.

3. What is the maximum operating temperature for the probe?

The maximum operating temperature for the 3300 XL proximity probe is +120°C, making it suitable for high-temperature industrial applications.

4. How accurate is the 3300 XL proximity probe?

The probe offers an accuracy of ±0.05 mm, which is highly precise for critical measurements in machinery monitoring.

5. Can the 3300 XL proximity probe be used for vibration measurement?

Yes, it is specifically designed for vibration monitoring and can detect imbalances, misalignments, and other faults in rotating machinery.

6. What is the output signal type of this proximity probe?

The 3300 XL 25mm proximity probe outputs a 4-20mA signal, which is standard for industrial monitoring systems.

7. What type of equipment is compatible with the 3300 XL proximity probe?

This probe is fully compatible with the Bently Nevada 3300 XL system and other compatible vibration and condition monitoring systems.

8. What materials is the 3300 XL proximity probe made of?

The probe is constructed from stainless steel, ensuring durability and resistance to corrosion in various industrial environments.

9. How is the 3300 XL proximity probe mounted?

It is designed for surface mounting on the machinery to monitor the rotating parts or shafts.

10. Is the 3300 XL proximity probe suitable for use in power plants?

Yes, the 3300 XL proximity probe is ideal for use in power plants, where it can monitor rotating equipment like turbines and pumps.

Related Product Recommendations

Here are some related models from the Bently Nevada 3300 XL series and other popular Bently Nevada models in the requested format:

| Model | Description |

|---|---|

| 330851-06-000-070-50-00-05 | Similar to the 25mm version, but with a 50mm range. |

| 330851-04-000-100-50-00-05 | Extended measurement range for larger machines. |

| 330851-04-000-010-10-00-05 | For more precise measurements in smaller machines. |

| 330851-04-000-015-50-00-05 | Provides higher accuracy for demanding applications. |

| 330851-04-000-080-20-00-05 | Ideal for high-vibration environments. |

| 330851-04-000-020-10-00-05 | A specialized version for monitoring critical machinery. |

Popular Bently Nevada Models

| Model | Description |

|---|---|

| 3500-33-02-01-00-00-01 | Advanced monitoring for vibration analysis. |

| 3500-42-02-01-00-00-01 | Multi-channel monitoring for complex systems. |

| 3500-22-02-01-00-00-01 | Measures vibration in machinery, compatible with 3500 series. |

| 3300-10-01-00-05-01 | For measuring rotational speed in machinery. |

| 3500-72-01-00-00-01 | A protective relay module for critical machinery. |

| 3500-91-01-00-00-01 | Signal conditioning for data integration. |

Excellent PLC

Excellent PLC