| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Introduction

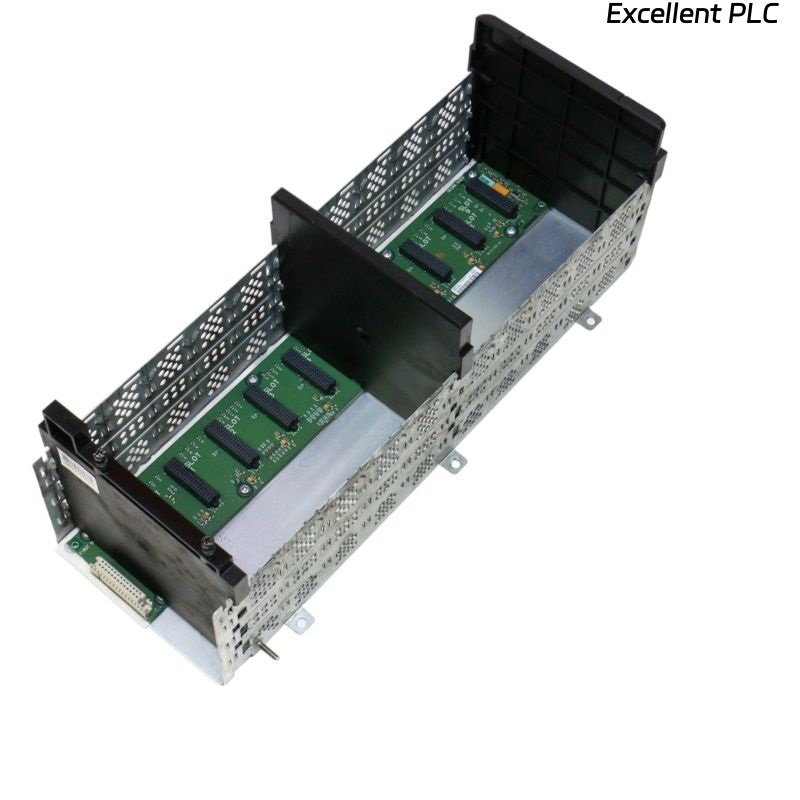

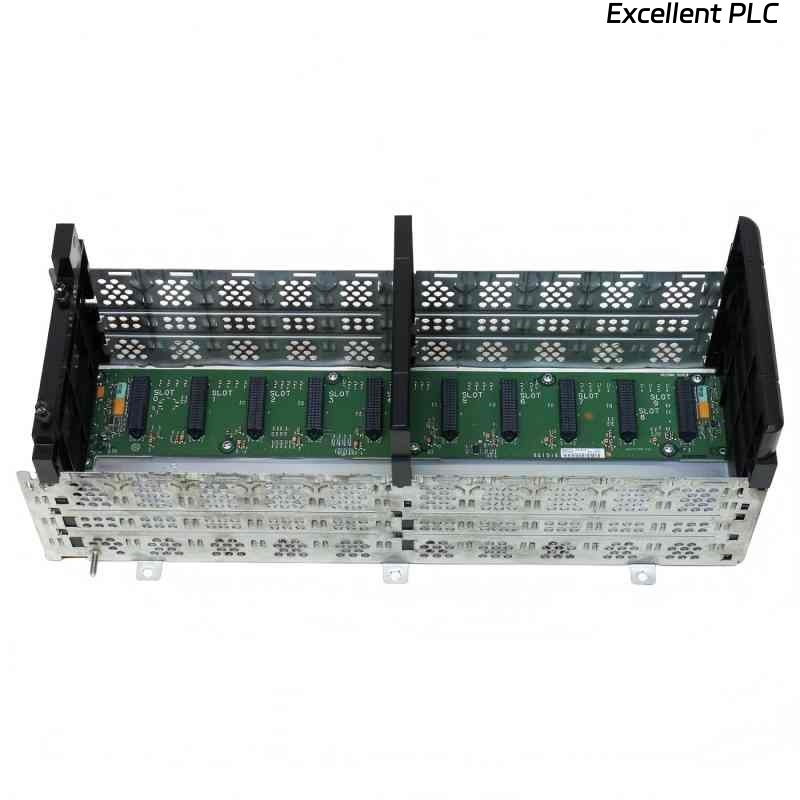

The Allen Bradley 1756‑A10 is a modular rack/chassis unit designed for the ControlLogix® system family, engineered by Rockwell Automation. It supports up to 10 plug‑in I/O or communication modules, offering a flexible infrastructure for industrial automation, control, and monitoring systems. As a horizontally mounted back‑panel chassis, it forms the backbone of the ControlLogix architecture, delivering high‑speed backplane communication and reliable power distribution to the modules inside.

The chassis meets demanding industrial standards, provides ease of maintenance, and supports future expansion thanks to its slot‑based architecture. With convection cooling and open‑style enclosure (in typical installations), it is suited for control‑panel environments where modularity and scalability matter.

Product Parameters

| Parameter | Value | Notes / Comments |

|---|---|---|

| Number of slots | 10 | Capacity for up to ten modules. |

| Cooling method | Convection | No forced‑air required; relies on panel airflow. |

| Mounting orientation | Horizontal only | The chassis is designed for horizontal back‑panel mounting. |

| Minimum enclosure size (HxWxD) | 50.8 × 76.2 × 20.3 cm (20 × 30 × 8 in) | For standard power‑supply version. |

| Approximate weight | 1.45 kg (3.2 lb) | Base chassis only; modules and power supply add to total. |

| Backplane current rating (chassis/slot) @ 1.2 V DC | 1.5 A / 1.5 A | |

| Backplane current rating @ 3.3 V DC | 4 A / 4 A | |

| Backplane current rating @ 5.1 V DC | 15 A / 6 A | |

| Backplane current rating @ 24 V DC | 2.8 A / 2.8 A | |

| Power dissipation (max) | 5 W | For the chassis itself under typical loads. |

| Operating temperature range | 0 °C to +60 °C (32 °F to 140 °F) | Standard environment. |

| Storage (non‑operating) temperature | –40 °C to +85 °C (–40 °F to 185 °F) | |

| Relative humidity (non‑condensing) | 5 % to 95 % RH | |

| Vibration (operating) | 2 g @ 10–500 Hz | |

| Shock (operating) | 30 g (unpackaged) |

Application Scenarios

The 1756‑A10 chassis is suited to a variety of industrial automation environments. Typical applications include:

-

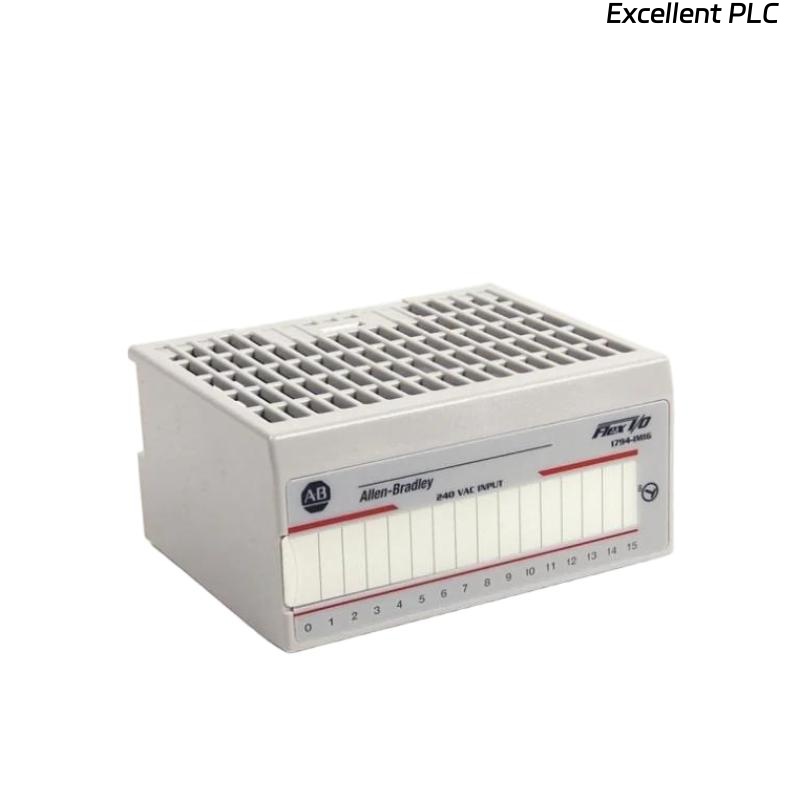

Large‑scale production lines or process plants where multiple I/O modules, communication adapters and specialty modules (motion, safety, high‑speed counter) are required.

-

OEM machine builders who need a modular rack to host a mix of control modules (digital I/O, analog I/O, communication, motion, safety) inside the same backplane infrastructure.

-

Distributed I/O architectures where remote racks feed back to a master controller via network modules inserted into the chassis.

-

Applications where future expansion is anticipated: starting with fewer modules and leaving unused slots available for future add‑ons helps reduce redesign cost.

-

Harsh industrial environments where the chassis will support modules that require robust power and backplane connectivity, as well as standard ambient conditions rated to 60 °C and strong vibration/shock tolerance.

Advantages (Key Strengths)

The 1756‑A10 offers several compelling advantages:

-

Modularity & Scalability: With 10 slots in one rack, you can mix and match a wide range of modules (I/O, communications, motion, safety). This flexibility reduces panel‑count and simplifies wiring architecture.

-

Unified Backplane Architecture: The backplane serves both data and power distribution, simplifying high‑speed communication between modules and reducing module-to-module wiring.

-

Expansion capability: Choosing a 10‑slot chassis offers future head‑room: you may initially populate fewer slots, leaving others free for growth without panel modification.

-

High reliability / industrial rating: The chassis meets rigorous environmental standards (vibration, shock, temperature, humidity) and employs horizontal mounting and convection cooling for longevity in industrial settings.

-

Standardized installation: Horizontal mounting, standard panel dimensions, and full compatibility with the ControlLogix ecosystem means easier integration, reduced engineering time and simplified stocking.

-

Efficient power distribution: By specifying chassis current ratings and power dissipation values, system designers can size the power supply and cooling appropriately.

-

Strong vendor support & ecosystem: Being a core component of the ControlLogix family ensures accessory availability (slot fillers, power supplies, adapters, documentation) and long‑term serviceability.

Excellent PLC

Excellent PLC