| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

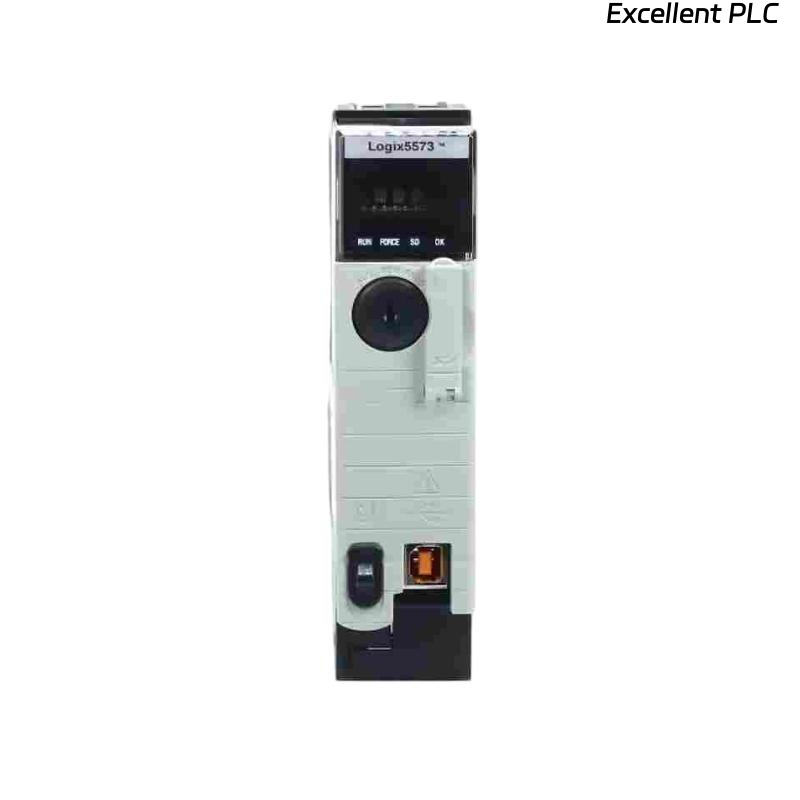

Introduction

The Allen Bradley 1756-L73 is a high-performance controller from the ControlLogix® 5570 series. It provides 8 MB of user memory, supports large I/O capacities, and is designed for complex automation systems that demand speed, scalability, and reliable communication. The controller is ideal for both discrete and process control environments, offering superior flexibility and integration with a wide range of industrial networks.

It fits directly into a 1756 series chassis and operates seamlessly with Rockwell Automation’s Studio 5000 or RSLogix 5000 software. With its modular architecture, the 1756-L73 simplifies system design, allowing engineers to build scalable control systems that can expand as needs evolve.

Product Parameters

| Parameter | Value | Notes / Comments |

|---|---|---|

| User memory | 8 MB | High-capacity memory for complex programs. |

| I/O non-volatile memory | 0.98 MB | Dedicated memory for I/O data retention. |

| On-board port | USB (programming only) | For configuration, download, and firmware updates. |

| Maximum digital I/O supported | 128,000 points | Ideal for large automation networks. |

| Maximum analog I/O supported | 4,000 points | Designed for high-precision process applications. |

| Power supply draw | 5 mA @ 1.2 V DC; 800 mA @ 5.1 V DC | Standard control power requirements. |

| Weight | 0.25 kg (0.55 lb) | Compact and lightweight. |

| Operating temperature | 0 °C to +60 °C (32 °F to 140 °F) | Standard ambient range. |

| Storage temperature | –40 °C to +85 °C (–40 °F to 185 °F) | Safe long-term storage. |

| Relative humidity | 5 % to 95 % non-condensing | Suitable for industrial environments. |

| Shock rating | 30 g | Robust for mechanical impact. |

| Vibration rating | 2 g, 10–500 Hz | For reliable operation under vibration. |

| Supported network protocols | EtherNet/IP™, ControlNet™, DeviceNet™, DH+, Remote I/O, SynchLink™ | Broad communication flexibility. |

Application Scenarios

The 1756-L73 controller is suitable for a wide range of automation and industrial control systems, including:

-

Manufacturing plants — Centralized control of large-scale production lines and process systems.

-

OEM machine builders — Modular control for machines requiring future expansion and multi-network integration.

-

Process industries — Advanced process control with analog and digital I/O handling.

-

Material handling systems — Coordinated motion control and communication between devices.

-

Energy and utilities — SCADA, DCS, and substation automation with reliable real-time control.

-

System upgrades — Migration path for users upgrading from older ControlLogix processors to higher performance controllers.

Advantages (Key Strengths)

-

High Performance & Memory: 8 MB user memory enables management of complex automation processes and extensive I/O configurations.

-

Scalability: Modular architecture supports easy expansion within the same chassis and network.

-

Advanced Task Handling: Supports up to 32 tasks and 100 programs per task for superior multitasking capability.

-

Network Integration: Compatible with major industrial protocols for seamless data exchange across systems.

-

Modular Flexibility: Can be installed in any slot of the 1756 chassis, with interchangeable modules for communication and I/O.

-

Reliable Design: Built to withstand harsh environments, with strong tolerance to vibration, temperature, and humidity.

-

Ease of Maintenance: Supports USB connectivity for programming and firmware updates through Studio 5000 software.

-

Long-term Compatibility: As part of the ControlLogix ecosystem, it ensures spare part availability and consistent support.

Excellent PLC

Excellent PLC