| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Introduction

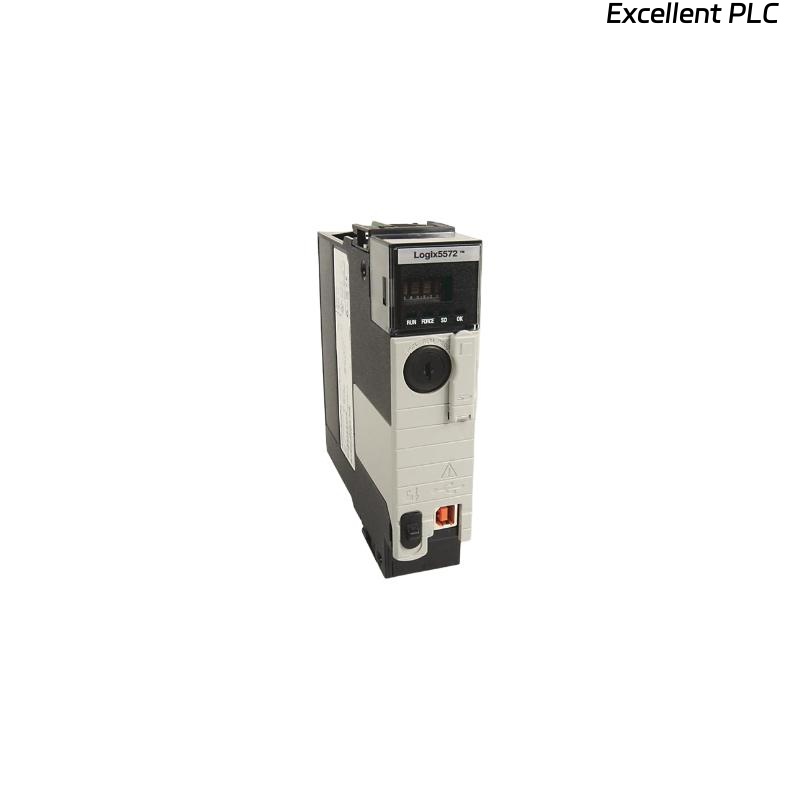

The Allen Bradley 1756-L72 is a high-performance ControlLogix 5561 L7 controller designed for complex industrial automation systems. Featuring 7 MB of user memory, dual EtherNet/IP ports with Device Level Ring (DLR) support, and advanced motion and process control capabilities, this controller is ideal for large-scale machine control, distributed I/O networks, and process automation. The 1756-L72 provides a balance of memory, connectivity, and processing power, making it suitable for demanding manufacturing and energy applications.

Technical Specifications

| Parameter | Specification | Notes / Comments |

|---|---|---|

| Controller Type | ControlLogix 5561 L7 | High-performance multi-task controller. |

| User Memory | 7 MB | Suitable for large and complex control programs. |

| Local I/O Expansion | Up to 32 modules | Supports extensive local I/O systems. |

| EtherNet/IP Nodes | Up to 64 nodes | Supports large distributed networks. |

| Communication Ports | 2 × EtherNet/IP, 1 × USB | Dual Ethernet supports DLR topology. |

| Ethernet Speed | 10/100/1000 Mbps | High-speed networking. |

| Non-Volatile Memory | SD Card (2 GB standard) | Stores programs, logs, and firmware. |

| Power Supply Voltage | 24 V DC | Standard industrial voltage. |

| Current Draw @5.1 V | ~1.5 A | From backplane. |

| Isolation Voltage | 30 V continuous, basic insulation | Between controller and system. |

| Operating Temperature | 0°C to +60°C | Suitable for industrial environments. |

| Storage Temperature | -40°C to +85°C | Non-operating range. |

| Relative Humidity | 5% to 95% non-condensing | Environmental tolerance. |

| Shock Rating | 30 g operational, 50 g non-op | Industrial standard. |

| Vibration | 5–2000 Hz @ 1 g | Resilient in harsh conditions. |

| Dimensions (H × W × D) | 203 mm × 55 mm × 129 mm | Approx. 8.0″ × 2.2″ × 5.1″. |

| Weight | 0.75 kg (≈1.65 lbs) | Full-featured, robust controller. |

Applications

The 1756-L72 controller is engineered for large and complex automation environments, including:

-

High-end Machine Control – Coordinating multiple motors, sensors, and axes.

-

Process Automation – Chemical, pharmaceutical, or food processing plants.

-

Factory Automation – Networks of distributed machines and devices over EtherNet/IP.

-

Energy & Utilities – Monitoring and controlling energy production, power generation, or distribution.

-

OEM Integration – Complex machinery requiring high memory and distributed control.

-

High-Availability Systems – Dual Ethernet ports enable DLR for redundancy and minimal downtime.

Advantages

-

Large Memory Capacity: 7 MB of user memory allows advanced control programs.

-

Dual Ethernet with DLR: Supports redundant network configurations for critical operations.

-

Expanded EtherNet/IP Node Support: Up to 64 nodes for distributed devices and I/O.

-

High-Speed Connectivity: Gigabit Ethernet enables fast communication and data transfer.

-

Modular and Scalable: Supports up to 32 local I/O modules for complex systems.

-

Robust Industrial Design: Designed for vibration, shock, humidity, and temperature extremes.

-

SD Card for Non-Volatile Storage: Stores program and firmware securely without batteries.

-

Seamless Studio 5000 Integration: Simplifies programming, diagnostics, and network management.

Excellent PLC

Excellent PLC