| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Executive Summary

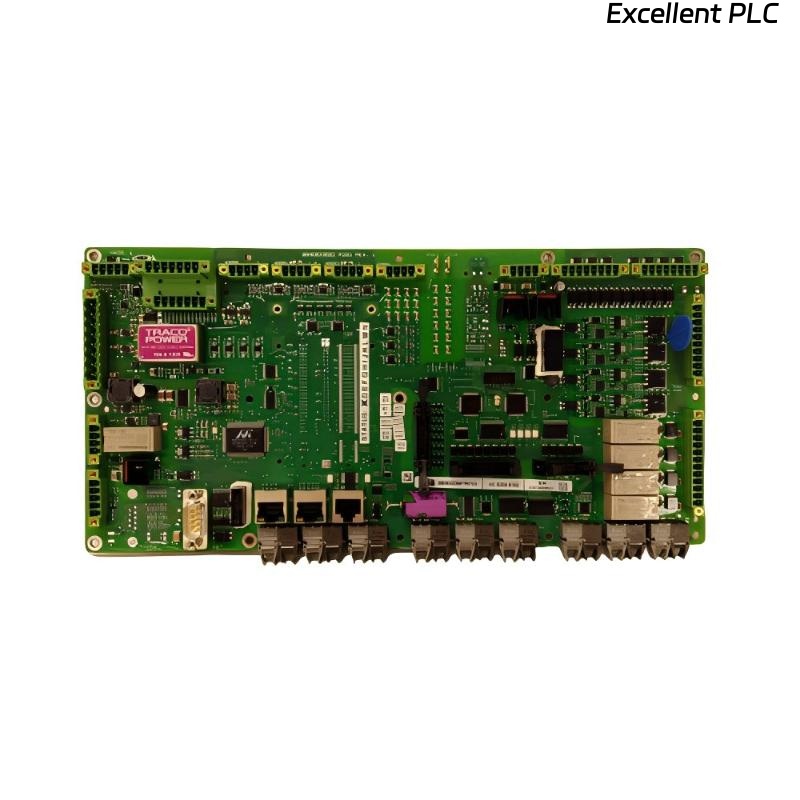

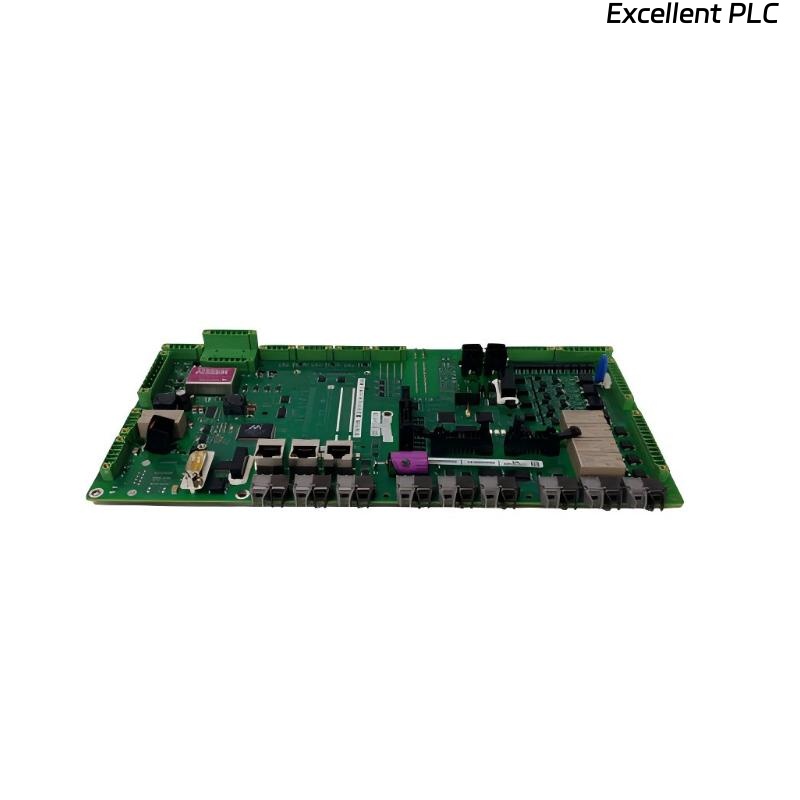

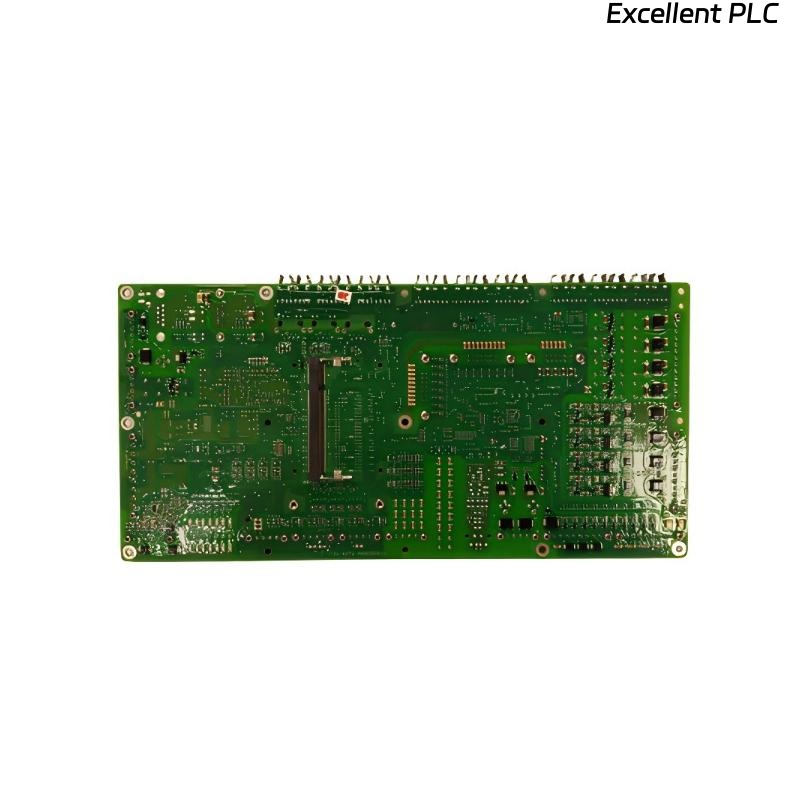

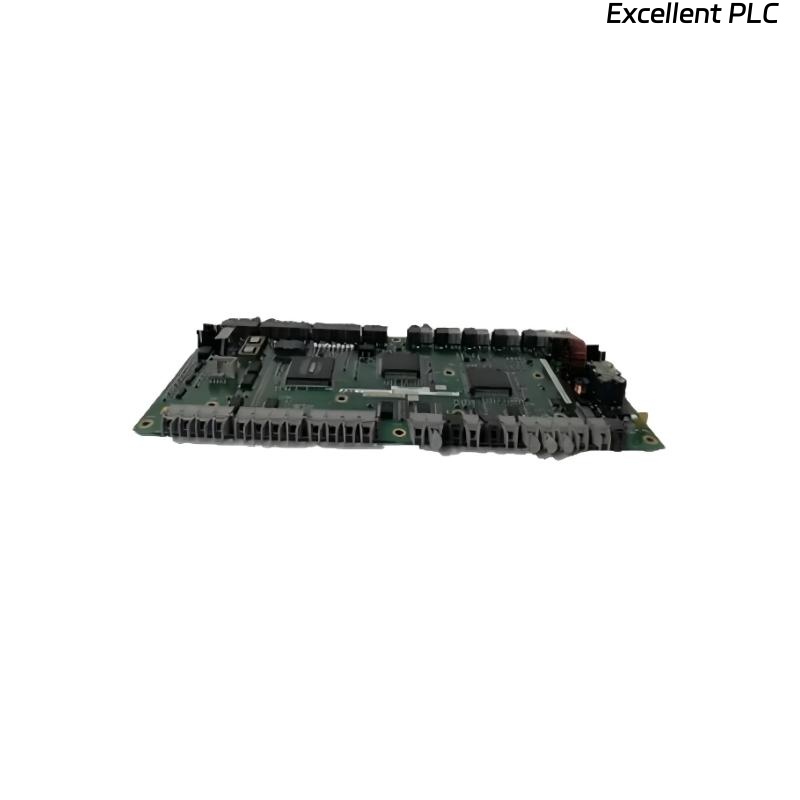

The ABB UC D224 A102 (3BHE023681R0102) Control Module is a high-performance process controller engineered for ABB’s Symphony Plus and Freelance Distributed Control Systems (DCS). It delivers powerful processing, flexible communication, and robust control logic suitable for mission-critical automation. Designed with ABB’s industrial-grade reliability, this module combines long-term stability, fast execution cycles, and multi-protocol connectivity, making it an ideal choice for complex process industries such as energy, petrochemical, and water treatment.

Technical Specifications

| Parameter | Specification | Description |

|---|---|---|

| Product Type | Process Control Module | Designed for ABB Symphony Plus / Freelance systems |

| Model Number | UC D224 A102 | Compact, high-speed control processor |

| Part Number | 3BHE023681R0102 | ABB product identification number |

| Processor | 32-bit RISC architecture | Optimized for real-time process applications |

| Memory | 64 MB RAM, 32 MB Flash | High-speed memory for control and logging |

| Communication Interfaces | Dual Ethernet, RS-485, System Bus | Redundant communication capability |

| Supported Protocols | Modbus TCP/IP, PROFIBUS DP, OPC | Industrial interoperability |

| Programming Environment | ABB Control Builder / Freelance Engineering Tool | IEC 61131-3 compliant |

| I/O Connectivity | Backplane connection to ABB I/O base units | Seamless DCS integration |

| Power Supply | 24 VDC nominal (19–30 VDC range) | Stable industrial power compatibility |

| Power Consumption | 12 W typical | Low-energy operation |

| Operating Temperature | 0 °C to +55 °C | Industrial environmental tolerance |

| Storage Temperature | -40 °C to +85 °C | Safe for long-term storage |

| Relative Humidity | 5% – 95% non-condensing | Built for harsh environments |

| Enclosure Type | DIN-rail or rack-mounted | Modular and serviceable design |

| Dimensions (H × W × D) | 128 mm × 35 mm × 150 mm (5.04″ × 1.38″ × 5.91″) | Compact form factor |

| Weight | 0.46 kg (1.01 lb) | Lightweight with industrial-grade durability |

Field Applications

-

Power and Energy Plants: Manages turbine and auxiliary systems with high precision and redundancy.

-

Oil & Gas Operations: Used in compressor control, pipeline automation, and refinery process units.

-

Chemical and Pharmaceutical Plants: Ensures consistent batch control and safety interlocks.

-

Water Treatment Facilities: Regulates flow control, filtration, and process sequencing.

-

Industrial Manufacturing Lines: Provides real-time logic and interlocking for machine coordination.

Major Advantages

-

High-Speed Logic Processing: 32-bit architecture enables sub-millisecond execution times.

-

Multi-Network Connectivity: Dual Ethernet and serial communication support complex topologies.

-

Seamless DCS Integration: Fully compatible with ABB’s Symphony Plus and Freelance environments.

-

Compact Modular Build: Allows for dense cabinet layouts without sacrificing accessibility.

-

Enhanced Reliability: EMI-hardened design suitable for high-interference industrial zones.

-

Redundancy-Ready Operation: Supports hot backup and fault-tolerant configurations.

-

Low Maintenance Demand: Built-in diagnostics and easy firmware updates via Ethernet.

-

Energy Efficient: Low 12 W power draw reduces system-level energy load.

-

Field-Proven Durability: Designed for 24/7 operation across varied industrial sectors.

-

Extended Lifecycle Support: Backed by ABB’s long-term product maintenance and parts program.

Excellent PLC

Excellent PLC