| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Overview

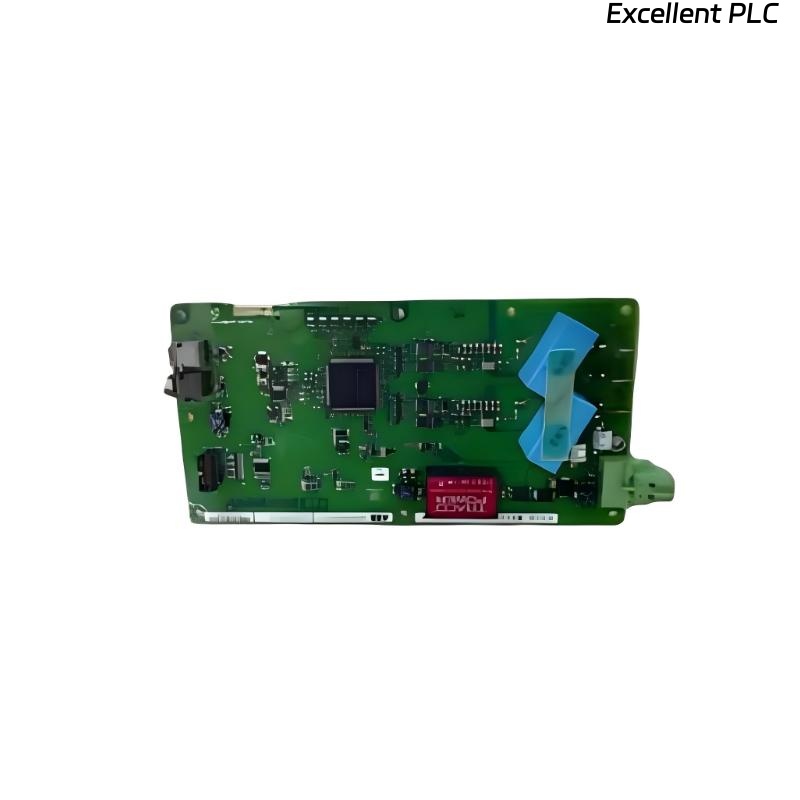

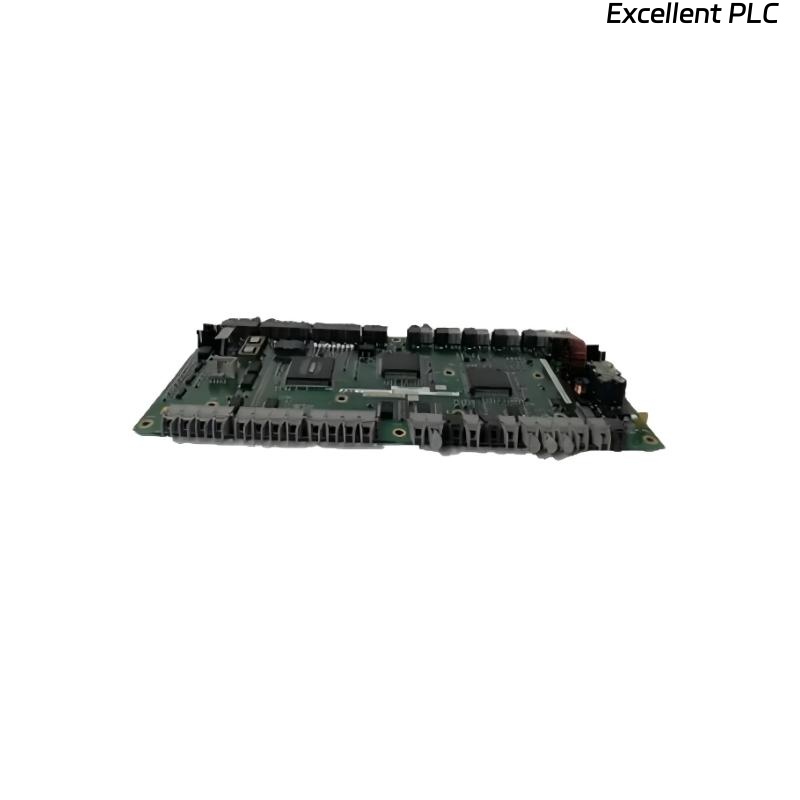

The ABB UD C920 BE101 (3BHE033489R0101) is a communication interface module designed to enhance data exchange and network reliability within ABB’s Symphony Plus and Freelance distributed control systems (DCS). It provides high-speed communication pathways between controllers, I/O systems, and supervisory networks, ensuring stable and synchronized process automation. Built with ABB’s industrial-grade reliability standards, the UD C920 BE101 serves as a critical bridge between control processors and field devices, offering real-time data handling and strong electromagnetic compatibility for demanding plant environments.

Key Specifications

| Parameter | Specification | Description |

|---|---|---|

| Product Type | Communication Interface Module | Provides network and fieldbus communication between controllers and systems |

| Model Number | UD C920 BE101 | Part of ABB’s Symphony Plus system family |

| Part Number | 3BHE033489R0101 | ABB catalog identification number |

| Processor Type | Embedded high-speed communication processor | Optimized for low-latency data handling |

| Communication Ports | Dual Ethernet, RS-485, System Bus | Supports redundant data links |

| Protocols Supported | Modbus TCP/IP, PROFIBUS DP, IEC 61850 | Broad industrial protocol compatibility |

| Memory | 64 MB SDRAM / 32 MB Flash | For network buffering and firmware management |

| Power Supply | 24 VDC nominal (19–30 VDC range) | Industry-standard low-voltage operation |

| Power Consumption | 10 W typical | Efficient and stable energy usage |

| Mounting Type | DIN-rail or rack-mounted | Supports flexible installation |

| Operating Temperature | 0°C to +55°C | Suitable for general industrial environments |

| Storage Temperature | -40°C to +85°C | Designed for long-term storage stability |

| Humidity | 5%–95% non-condensing | Tolerant of industrial humidity conditions |

| EMC Compliance | IEC/EN 61000 | Meets global EMC standards |

| Dimensions (H × W × D) | 128 mm × 35 mm × 150 mm (5.04″ × 1.38″ × 5.91″) | Compact module size for cabinet integration |

| Weight | 0.42 kg (0.93 lb) | Lightweight, robust structure |

Use Cases and Industrial Integration

-

Power Generation Systems: Facilitates real-time data transfer between turbine controllers and plant DCS networks.

-

Oil & Gas Automation: Ensures secure communication between distributed PLCs and SCADA interfaces.

-

Chemical and Process Plants: Provides deterministic data exchange for process control and monitoring.

-

Water and Wastewater Management: Enables continuous monitoring and remote diagnostics across treatment networks.

-

Pulp and Paper Industry: Synchronizes high-speed control loops and data logs between production stages.

Core Benefits

-

Enhanced Data Throughput: Designed for high-speed Ethernet communication and fast response times.

-

Reliable Redundancy: Dual-port architecture supports redundant topologies and hot-standby modes.

-

Broad Protocol Support: Natively compatible with multiple ABB and third-party communication standards.

-

Industrial Durability: Rugged design with EMC shielding for high-interference zones.

-

Ease of Integration: Plug-and-play setup with ABB DCS configuration tools.

-

Scalable Performance: Can operate standalone or in distributed network clusters.

-

Secure Data Handling: Firmware-level encryption for communication integrity.

-

Energy Efficient: Operates with low power draw and minimal heat output.

-

Field Serviceability: Hot-swappable module design for minimal downtime.

-

Future-Proof Architecture: Compatible with ABB’s next-generation control networks.

Excellent PLC

Excellent PLC