| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

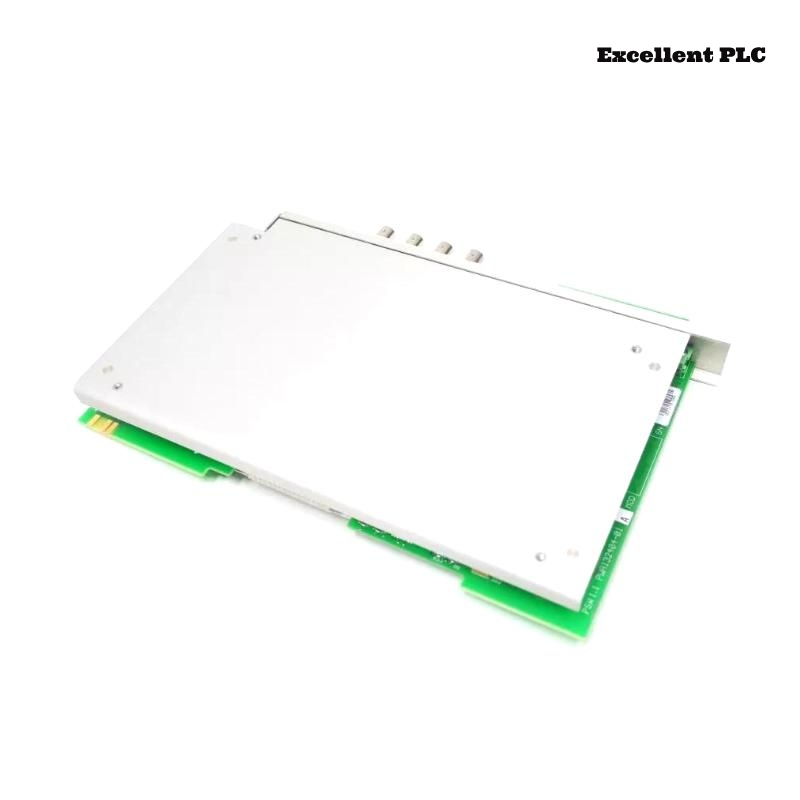

The Bently Nevada 132417-01 190662-26 is a four-channel monitor specifically designed for integration with Solar Turbines. This high-precision instrument is part of Bently Nevada’s renowned monitoring systems, providing real-time surveillance of critical parameters in industrial machinery. Its primary function is to monitor vibration levels in reciprocating compressors, particularly focusing on the crankcase and crosshead components. By receiving inputs from seismic sensors, it processes these signals to deliver accurate vibration measurements, ensuring machinery operates within safe parameters.

Product Specifications

| Parameter | Description |

|---|---|

| Model Number | 132417-01 |

| Part Number | 190662-26 |

| Manufacturer | Bently Nevada |

| Channels | 4 |

| Monitored Parameters | Vibration (Crankcase and Crosshead) |

| Sensor Compatibility | Seismic Sensors |

| Operating Temperature | -20°C to +65°C |

| Power Supply | 24 V DC |

| Dimensions | 241 x 24.4 x 99.1 mm |

| Weight | 0.45 kg |

| Mounting | Rack-mounted |

| Compliance | CE, RoHS |

| Display | LED Indicators for Channel Status |

| Alarm Outputs | Configurable Relay Outputs |

| Communication Interface | RS485 |

Applications

The Bently Nevada 132417-01 190662-26 Four-Channel Monitor is utilized across various industrial sectors, including:

- Oil & Gas Industry: Monitoring vibration in reciprocating compressors to prevent unexpected downtimes.

- Power Generation: Ensuring the reliability of turbines and associated machinery by tracking critical vibration parameters.

- Petrochemical Plants: Overseeing the performance of compressors and pumps to maintain optimal operational efficiency.

- Manufacturing: Supervising heavy machinery to detect anomalies early and schedule preventive maintenance.

- Marine Engineering: Monitoring engine vibrations to ensure the safety and efficiency of marine vessels.

Product Advantages

- Multi-Channel Monitoring: Simultaneously observes four channels, allowing comprehensive surveillance of machinery components.

- High Precision: Delivers accurate vibration measurements, facilitating early detection of potential issues.

- Real-Time Data Processing: Provides immediate insights into machinery health, enabling prompt responses to anomalies.

- Robust Compatibility: Integrates seamlessly with various seismic sensors, offering flexibility in monitoring setups.

- User-Friendly Interface: Features LED indicators and configurable outputs for straightforward operation and integration.

- Durable Design: Engineered to withstand harsh industrial environments, ensuring longevity and reliability.

- Compact Form Factor: Its rack-mounted design saves space and simplifies installation.

- Energy Efficient: Operates on a low power supply, reducing energy consumption.

- Compliance with Standards: Adheres to international safety and environmental standards, ensuring safe operation.

- Enhanced Safety: Early detection of vibration anomalies helps prevent catastrophic machinery failures.

Latest News & Updates

- “Advancements in Vibration Monitoring: Bently Nevada’s Four-Channel Solutions”

- “Integrating Bently Nevada Monitors with Solar Turbines for Enhanced Efficiency”

- “The Role of Seismic Sensors in Modern Industrial Monitoring Systems”

- “Preventive Maintenance: How Vibration Monitoring Reduces Downtime”

- “Bently Nevada’s Commitment to Sustainable and Reliable Monitoring Solutions”

Frequently Asked Questions (FAQ)

-

What is the primary function of the Bently Nevada 132417-01 190662-26 monitor?

- It monitors vibration levels in reciprocating compressors, focusing on the crankcase and crosshead areas.

-

How many channels does this monitor support?

- It supports four independent channels.

-

Which sensors are compatible with this monitor?

- It is compatible with seismic sensors designed to detect vibration.

-

Can this monitor operate in extreme temperatures?

- Yes, it operates within a temperature range of -20°C to +65°C.

-

What are the dimensions of the monitor?

- The monitor measures approximately 241 mm in height, 24.4 mm in width, and 99.1 mm in depth.

-

Is the monitor compliant with international standards?

- Yes, it complies with CE and RoHS standards.

-

How is the monitor mounted?

- It is designed for rack-mounted installations.

-

Does the monitor provide real-time data?

- Yes, it offers real-time data processing and monitoring.

-

What type of power supply is required?

- It requires a 24 V DC power supply.

-

Are there alarm features included?

- Yes, it has configurable relay outputs for alarms.

Related Models in the Bently Nevada Series

| Model Number | Description |

|---|---|

| 3500/42M | Proximitor Seismic Monitor |

| 3500/44M | Aeroderivative Gas Turbine Monitor |

| 3500/50 | Tachometer Module |

| 3500/60 | Temperature Monitor |

| 3500/64M | Dynamic Pressure Monitor |

| 3500/65 | Velocity Monitor |

| 3500/70M | Reciprocating Compressor Monitor |

| 3500/72M | Rod Position Monitor |

| 3500/92 | Communication Gateway Module |

| 3500/94 | VGA Display Module |

Popular Models from Bently Nevada

| Model Number | Description |

|---|---|

| 3300 XL | 8 mm Proximity Probes |

| 330500 | Velomitor Piezo-velocity Sensor |

| 3701/55 | Hazardous Area Monitoring System |

| 990 Vibration Transmitter | Loop-powered Vibration Transmitter |

| 2300/20 | Vibration Monitor |

| 1900/65A | General Purpose Equipment Monitor |

| 3500/33 | Relay Module |

| 3500/25 | Enhanced Keyphasor Module |

| 3500/15 | Power Supply Module |

| 3500/22M | Transient Data Interface |

Excellent PLC

Excellent PLC