| Company Information | ||||||||

| sales@xmjzjsgs.com | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

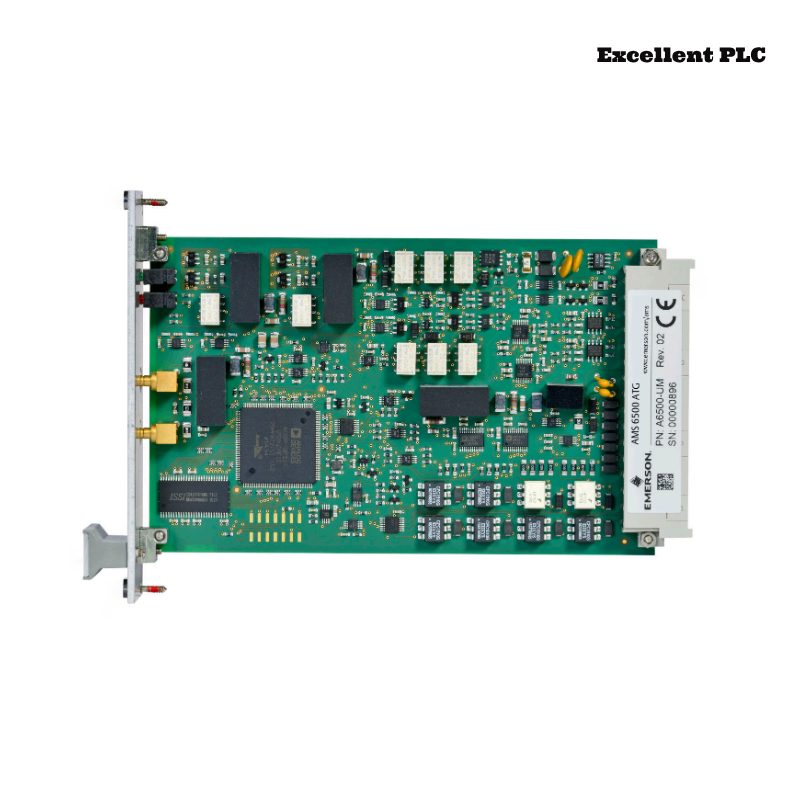

Product Overview

The A6500-UM Universal Measurement Card is engineered to interface with a wide array of sensor types, including eddy-current, piezoelectric (accelerometer or velometer), seismic (electro-dynamic), low-frequency bearing vibration (LF), Hall-effect, and Linear Variable Differential Transformer (LVDT) sensors (when combined with the A6500-LC). This flexibility allows it to effectively monitor parameters such as shaft vibration, casing vibration, displacement, and rotational speed, making it an essential tool for maintaining machinery health.

Product Specifications

Below is a detailed table outlining the key specifications of the A6500-UM Universal Measurement Card:

| Parameter | Specification |

|---|---|

| Input Channels | 2 (independent or combined, depending on measurement mode) |

| Compatible Sensors | Eddy-current, piezoelectric (accelerometer or velometer), seismic (electro-dynamic), LF (low-frequency bearing vibration), Hall-effect, LVDT (with A6500-LC) |

| Digital Inputs | 5 |

| Digital Outputs | 6 |

| Buffered Outputs | Front and rear |

| Proportional Outputs | 0/4–20 mA |

| Power Supply Voltage | 24 VDC |

| Operating Temperature Range | -40°C to +85°C (-40°F to +185°F) |

| Storage Temperature Range | -40°C to +95°C (-40°F to +203°F) |

| Humidity | 5% to 95% RH (non-condensing) |

| Vibration Tolerance | 0.03 inches peak-to-peak, 10 to 500 Hz |

| Shock Tolerance | 15 G, 11 ms, half-sine wave |

| Dimensions | 100 x 160 mm |

| Weight | 0.2 kg |

Product Applications

The A6500-UM is utilized in various industrial settings, including:

- Rotating Machinery: Monitoring pumps, compressors, turbines, and generators to detect anomalies in vibration, displacement, and speed.

- Process Equipment: Ensuring the operational integrity of critical process machinery by monitoring vibration and other parameters.

- Manufacturing Systems: Overseeing the health of manufacturing equipment to prevent unexpected downtime and maintain product quality.

- Power Generation: Monitoring turbines and generators in power plants to ensure efficient and safe operation.

- Oil and Gas Operations: Supervising the condition of equipment used in extraction, refining, and transportation processes to prevent failures and enhance safety.

Product Advantages

The A6500-UM offers several benefits:

- Enhanced Machinery Protection: Provides comprehensive monitoring to prevent equipment failures.

- Flexible Sensor Compatibility: Supports various sensor types, allowing for tailored monitoring solutions.

- High Precision: Delivers accurate measurements, facilitating reliable data analysis.

- Scalability: Easily integrates into existing systems, accommodating future expansion.

- Cost Efficiency: By enabling predictive maintenance, it reduces downtime and maintenance costs.

Recent News Headlines

While specific recent news articles about the A6500-UM are not available in the provided sources, Emerson continues to innovate in machinery health monitoring, with the A6500-UM being a testament to their commitment to advancing industrial automation solutions.

Frequently Asked Questions (FAQs)

-

What types of sensors are compatible with the A6500-UM?

- The card supports eddy-current, piezoelectric (accelerometer or velometer), seismic (electro-dynamic), low-frequency bearing vibration (LF), Hall-effect, and LVDT sensors (when combined with the A6500-LC).

-

Can the A6500-UM monitor multiple parameters simultaneously?

- Yes, it can monitor various parameters such as shaft vibration, casing vibration, displacement, and speed concurrently.

-

Is the A6500-UM suitable for high-temperature environments?

- It operates effectively within a temperature range of -40°C to +85°C (-40°F to +185°F).

-

How does the A6500-UM integrate with existing systems?

- It communicates via an internal RS485 bus to the A6500-CC communication card, which converts signals to Modbus RTU and Modbus TCP/IP protocols for integration with host or analysis systems.

-

What are the power requirements for the A6500-UM?

- The card requires a 24 VDC power supply.

-

Does the A6500-UM support remote configuration?

- Yes, it allows for remote selectable limit multiples and trip bypasses, facilitating flexible configuration.

-

What are the dimensions and weight of the A6500-UM?

- The card has a 3U size, single-slot plug-in module design, and weighs 0.2 kg.

-

How does the A6500-UM handle signal outputs?

- It provides front and rear buffered outputs, as well as proportional outputs ranging from 0/4–20 mA.

-

Is the A6500-UM compliant with industry standards?

- Yes, it is designed to meet industry monitoring hardware standards, ensuring reliability and compatibility.

-

What digital input and output capabilities does the A6500-UM have?

- The card includes 5 digital inputs and 6 digital outputs, enhancing its monitoring and control capabilities.

Related Models in the Same Series or Category

| Model | Description |

|---|---|

| A6500-TP | Temperature Process Card designed to monitor temperature-related parameters in machinery. |

| A6500-RC | Relay Card used for managing relay outputs within the AMS 6500 ATG system. |

| A6500-CC | Communication and Rack Interface Module facilitating data transmission and system integration. |

| A6500-SR | System Rack capable of housing multiple protection cards, including the A6500-UM and A6500-TP. |

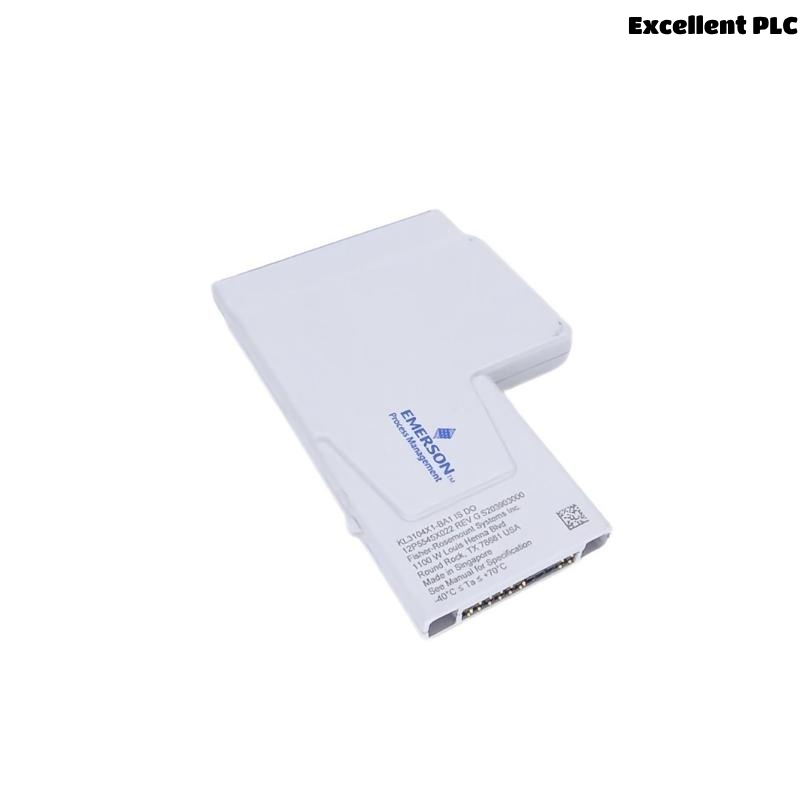

| A6500-LC | LVDT Converter Module enabling the use of LVDT sensors with the AMS 6500 system. |

| CSI 6500 | Machinery Health Monitor offering comprehensive monitoring and protection features. |

| CSI 6300 | SIS Digital Overspeed Protection System designed for critical machinery protection. |

| CSI 2140 | Machinery Health Analyzer providing advanced vibration analysis and diagnostics. |

| CSI 9420 | Wireless Vibration Transmitter enabling remote monitoring of vibration parameters. |

| CSI 5200 | Machinery Health Protection System offering scalable monitoring solutions for various applications. |

Popular Models from Emerson

| Model | Description |

|---|---|

| Rosemount 3051 | Pressure Transmitter known for its accuracy and reliability in pressure measurement. |

| Rosemount 5408 | Non-Contacting Radar Level Transmitter suitable for level measurement in various applications. |

| DeltaV DCS | Distributed Control System offering advanced process control and automation capabilities. |

| Ovation DCS | Control System designed specifically for the power generation industry. |

| AMS Trex | Device Communicator facilitating field device configuration and diagnostics. |

| Micro Motion Coriolis | Flow Meter providing precise mass flow and density measurements. |

| Fisher Control Valves | Range of control valves known for their performance and durability in process control. |

| Roxar 2600 | Multiphase Flow Meter used in oil and gas applications to measure flow rates of oil, gas, and water. |

| SolaHD Power Supplies | Industrial power supplies ensuring reliable power delivery in automation systems. |

| PACSystems RX3i | Programmable Automation Controller offering scalable and flexible control solutions. |

Excellent PLC

Excellent PLC