| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

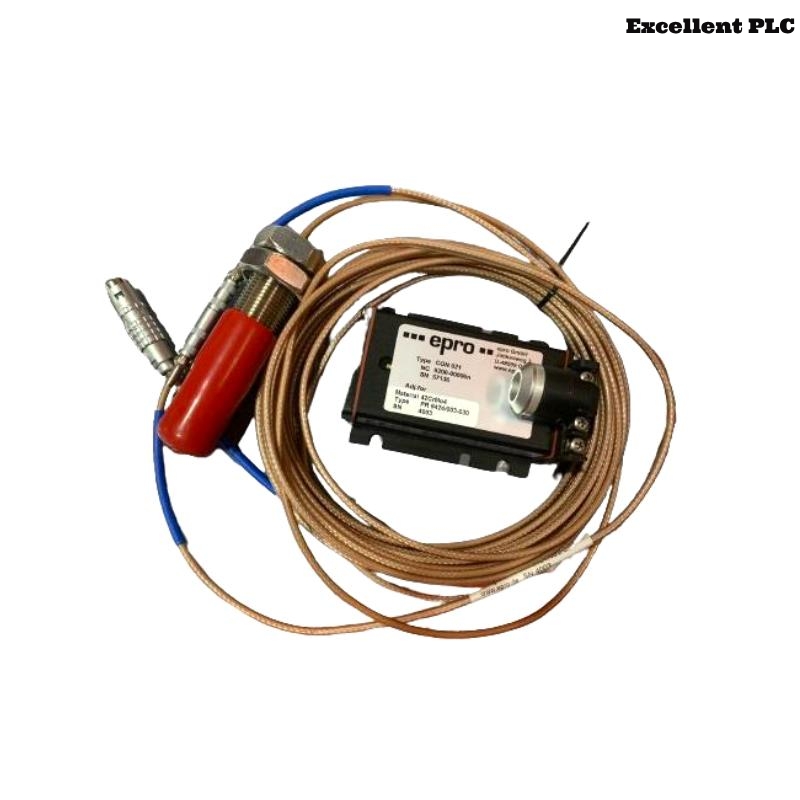

The Emerson EPRO PR6424/002-030 is a high-precision, non-contact eddy current sensor designed for critical turbomachinery applications. It accurately measures radial and axial shaft dynamic displacement, position, eccentricity, and speed/key in rotating machinery. Its robust design ensures reliable performance in harsh industrial environments, making it an essential component for monitoring and protecting vital equipment such as turbines, compressors, pumps, and fans.

Product Specifications

| Parameter | Details |

|---|---|

| Model Number | PR6424/002-030 |

| Sensor Type | Eddy Current Displacement Sensor |

| Measurement Principle | Non-contact eddy current |

| Sensitivity/Linearity | 4 V/mm (101.6 mV/mil) ±1.5% |

| Air Gap (Center) | Approx. 2.7 mm (0.11″) Nominal |

| Static Measurement Range | ±2.0 mm (0.079″) |

| Dynamic Measurement Range | 0 to 1,000 µm (0 to 0.039″) |

| Long-Term Drift | < 0.3% |

| Shaft Diameter | ≥ 80 mm |

| Operating Temperature | -35°C to +180°C (-31°F to +356°F) |

| Shock and Vibration | 5g @ 60 Hz @ 25°C (77°F) |

| Target Material | Ferromagnetic Steel (42 Cr Mo4 Standard) |

| Maximum Surface Speed | 2,500 m/s (98,425 ips) |

| Material | Sleeve – Stainless Steel; Cable – PTFE |

| Sensor Head Diameter | 16 mm |

| Weight | 0.2 kg |

| Mounting Type | Field or enclosure mounting |

| Certifications | CE, UL, RoHS |

Product Applications

The PR6424/002-030 sensor is widely used in various industries for monitoring and diagnostic purposes:

-

Steam, Gas, and Hydro Turbines: Measures shaft displacement and vibration to ensure efficient operation.

-

Compressors: Monitors axial and radial movements to prevent mechanical failures.

-

Pumps and Fans: Detects misalignments and imbalances to maintain optimal performance.

-

Generators: Ensures stability by tracking shaft position and movement.

-

Industrial Machinery: Provides real-time data for predictive maintenance and system optimization.

Product Advantages

-

High Precision: Offers accurate measurements with minimal drift, ensuring reliable data over time.

-

Non-Contact Measurement: Eliminates mechanical wear, reducing maintenance requirements.

-

Robust Design: Withstands harsh environments, including high temperatures and vibrations.

-

Versatile Applications: Suitable for various machinery and operational conditions.

-

Easy Integration: Compatible with standard monitoring systems and signal converters.

-

Compliance with Standards: Meets international safety and environmental certifications.

Frequently Asked Questions (FAQ)

-

What is the primary function of the PR6424/002-030 sensor?

-

It measures radial and axial shaft dynamic displacement, position, eccentricity, and speed/key in rotating machinery.

-

-

Is the sensor suitable for high-temperature environments?

-

Yes, it operates effectively in temperatures ranging from -35°C to +180°C.

-

-

Can the sensor be used with different shaft sizes?

-

It is designed for shafts with diameters of 80 mm or larger.

-

-

What materials are compatible with the sensor’s measurement capabilities?

-

It is optimized for ferromagnetic steel, specifically 42 Cr Mo4 standard.

-

-

How is the sensor mounted?

-

It can be mounted in the field or within an enclosure, depending on the application requirements.

-

-

Does the sensor require regular calibration?

-

Due to its low drift (<0.3%), it requires minimal calibration over its operational lifespan.

-

-

Is the sensor resistant to vibrations and shocks?

-

Yes, it can withstand shocks and vibrations up to 5g at 60 Hz and 25°C.

-

-

What is the weight of the sensor cable?

-

0.2 kg.

-

-

Is the sensor compliant with international standards?

-

Yes, it holds CE, UL, and RoHS certifications.

-

-

Can the sensor be integrated with existing monitoring systems?

-

Yes, it is compatible with standard monitoring systems and signal converters like the CON021.

-

Related Models from the Same Series or Functionality (Epro PR6424 Series)

| Model Number | Description |

|---|---|

| PR6424/000-100 | 16mm Eddy Current Sensor with standard range and cable assembly |

| PR6424/002-100 | 16mm Sensor with extended temperature range capability |

| PR6424/010-030 | 16mm Sensor with straight connector and compact design |

| PR6424/003-030 | 16mm Sensor for shorter mounting locations |

| PR6424/005-010+CON021 | 16mm Sensor + CON021 signal converter set, used in dual-channel setups |

| PR6424/01CS | Customized 16mm sensor for specific OEM configurations |

Popular Models from the Same Brand (Epro/Emerson)

| Model Number | Type | Description |

|---|---|---|

| PR6423/002-030 | Eddy Current Sensor (5mm) | High-resolution 5mm probe for compact installations |

| PR6423/003-010 | Eddy Current Sensor (8mm) | Versatile sensor for medium-sized shaft monitoring |

| MMS3120/022-100 | Vibration Monitor Module | Part of the MMS series for rotating machinery protection |

| MMS6120/000-000 | Diagnostic Module | Advanced module for vibration and speed signal processing |

| CON011 | Signal Converter | Interface between PR6423/24 sensors and diagnostic systems |

| CON021 | Advanced Signal Conditioner | Provides power and signal interface for Epro sensors |

Excellent PLC

Excellent PLC