| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

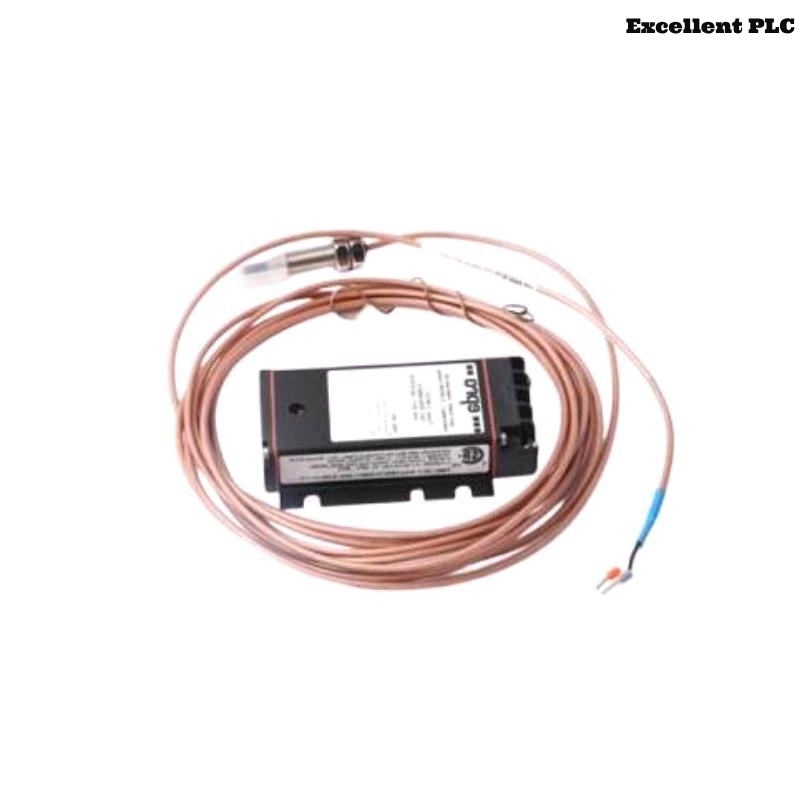

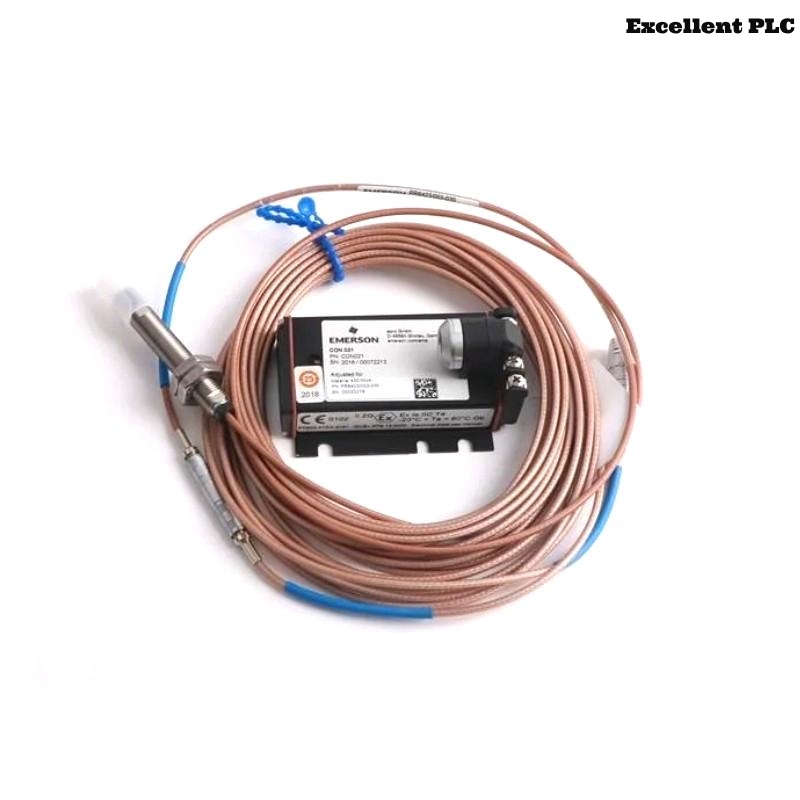

The Epro PR6423/00E-030 is a high-precision, non-contact eddy current proximity sensor designed for continuous vibration and displacement monitoring in rotating machinery. With an 8 mm tip diameter and a measurement range optimized for mid-range shaft gaps and dynamic motion, the sensor is built to operate reliably under harsh industrial conditions such as high temperatures, high vibration levels, and contaminated environments.

This model belongs to Epro’s PR6423 series, well-known in turbomachinery condition monitoring. Paired typically with the CON0x1 connection units and suitable monitoring modules (such as the MMS6000 series), the sensor delivers consistent and accurate output for critical applications in power plants, petrochemical facilities, refineries, and OEM turbomachinery systems.

Product Specifications

| Parameter | Description |

|---|---|

| Model Number | PR6423/00E-030 |

| Sensing Principle | Eddy Current (non-contact) |

| Probe Tip Diameter | 8 mm |

| Measurement Range | 0.25 mm to 2.0 mm (typical dynamic range) |

| Linear Range | ±1.0 mm |

| Calibration Target | AISI 4140 steel or equivalent (standard) |

| Sensitivity | Nominal 7.87 mV/μm |

| Frequency Range | DC to 10 kHz |

| Power Supply (via CON module) | 24 VDC (typically through CON011/CON021) |

| Operating Temperature Range | -35°C to +180°C |

| Storage Temperature Range | -40°C to +200°C |

| Probe Material | Stainless steel, hermetically sealed |

| Cable Type | Integrated mineral insulated (MI) cable, shielded |

| Cable Length | 3 meters (specified by “-030” in model) |

| Connector | Compatible with CON011, CON021 connection units |

| Mounting Thread | M10 x 1.0 (custom options available) |

| Mounting Torque | 2.0 Nm (recommended) |

| Weight | 0.1 kg |

| Protection Rating | IP67 |

| Certifications | CE, ATEX (when used with appropriate accessories) |

Product Applications

-

Steam and Gas Turbines

Used for continuous shaft vibration monitoring and position measurement to ensure safe operation of turbines. -

Compressors and Pumps

Helps detect imbalance, misalignment, and bearing wear in axial and radial directions for rotating machinery. -

Motors and Generators

Enables predictive maintenance by tracking vibration levels over time and detecting early-stage mechanical degradation. -

Hydroelectric Machinery

Ideal for large-scale power generation applications requiring robust and reliable proximity measurement. -

Petrochemical Industry

Commonly deployed in API 670-compliant systems for condition monitoring in refineries and chemical plants. -

OEM Machinery and Test Benches

Frequently integrated into custom-built rotating test rigs and equipment for R&D or QA testing.

Product Advantages

-

High Temperature Capability

The sensor is engineered to function reliably in environments up to +180°C, making it ideal for steam turbines and hot process zones. -

Excellent Signal Stability

Offers long-term stability with minimal drift, ensuring accurate vibration data over extended operation periods. -

Precision Manufacturing

German-engineered to exact tolerances, ensuring reliable calibration and tight linearity performance. -

Seamless Integration

Fully compatible with Epro’s CON series (CON011, CON021) and monitoring systems like MMS6000 and VM600. -

Compact Form Factor

The 8 mm diameter allows it to be installed in confined areas or OEM machinery with space constraints. -

Robust Mechanical Design

Stainless steel housing and MI cable ensure durability in demanding industrial environments. -

IP67 Protection

Suitable for wet and dusty installations without additional sealing. -

Field Proven

Trusted by OEMs and major industrial users worldwide in continuous process and critical machinery protection systems.

Frequently Asked Questions (FAQs)

-

What is the sensing range of the PR6423/00E-030 sensor?

The typical linear sensing range is from 0.25 mm to 2.0 mm, optimized for mid-range shaft displacement and vibration. -

What cable length does the “-030” suffix represent?

The “-030” suffix indicates a 3-meter cable length, permanently integrated into the sensor body. -

Is this sensor compatible with Bently Nevada systems?

No, it is designed specifically for use with Epro systems (e.g., CON011, CON021, MMS6000), though signal-level adaptation may be possible with engineering. -

Can this sensor operate in high-temperature zones?

Yes, it is rated for continuous operation at up to +180°C, with a storage limit of +200°C. -

Does this sensor meet API 670 standards?

Yes, when used with the appropriate monitoring and connection modules, it can be part of an API 670-compliant system. -

How is the sensor mounted?

The sensor uses an M10 x 1.0 mounting thread. It should be installed with a recommended torque of 2.0 Nm. -

What is the typical sensitivity of this model?

Nominal sensitivity is around 7.87 mV/μm (micro-meter), depending on the system configuration. -

Is the cable field replaceable?

No, the MI cable is integrated and not replaceable in the field. Cable length must be specified at the time of ordering. -

Does it require external signal conditioning?

Yes, it must be used in conjunction with a compatible connection unit (e.g., CON011 or CON021) to function correctly. -

What is the protection rating?

The PR6423/00E-030 is rated IP67, offering protection against water and dust ingress.

Related or Similar Epro Models

| Model Number | Description | Probe Tip | Cable Length | Max Temp |

|---|---|---|---|---|

| PR6423/000-030 | Standard 8mm probe, uncalibrated variant | 8 mm | 3 m | 180°C |

| PR6423/002-030 | 5 mm probe, calibrated, shorter range | 5 mm | 3 m | 180°C |

| PR6423/003-030 | 11 mm tip for larger shaft gaps | 11 mm | 3 m | 180°C |

| PR6423/005-010 | 8 mm probe with 1 m cable, axial mounting | 8 mm | 1 m | 180°C |

| PR6423/00R-030 | Right-angle 8 mm probe | 8 mm | 3 m | 180°C |

| PR6423/004-010 | Ultra-high temp variant, 8 mm tip | 8 mm | 1 m | 220°C |

Popular Epro Models from the Same Brand

| Model Number | Description | Type | Application Area |

|---|---|---|---|

| CON011 | Connection unit for PR6423 series | Signal Conditioner | Turbomachinery Monitoring |

| MMS3120/022-100 | Vibration Monitoring Module | Monitor Module | API 670 Systems |

| PR6424/010-010 | Displacement Sensor with 10 mm tip | Eddy Current Sensor | Axial Displacement |

| CON021 | Dual-channel Connection Unit | Signal Conditioner | Redundant Systems |

| MMS6410 | Online Monitoring System | Full Monitoring Unit | Centralized DCS |

| PR9268/201-100 | Velocity Sensor for casing vibration | Velocity Transducer | Bearing Housing Vibration |

Excellent PLC

Excellent PLC