| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

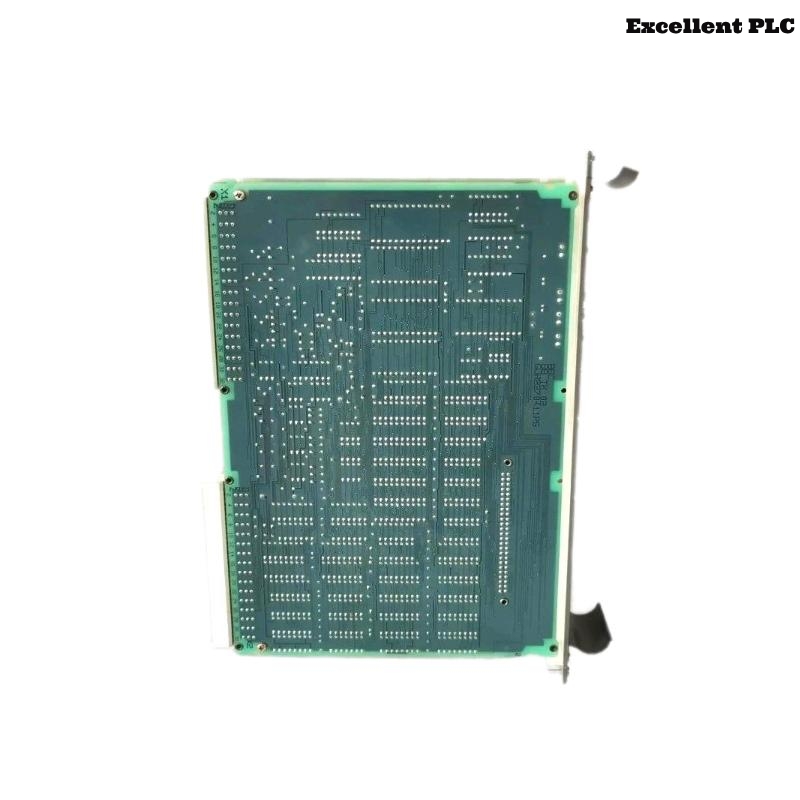

The ABB 88VT02 GJR2363900R1000 Printed Circuit Board (PCB) is a critical electronic component used within ABB’s industrial automation platforms. It is part of the Advant Controller 31 and related control systems, specifically designed for reliable data processing, I/O signal conditioning, and control logic execution. Built to meet the stringent demands of industrial environments, the 88VT02 PCB ensures system reliability, long-term operation, and electrical performance across various critical applications.

As part of ABB’s trusted portfolio, the 88VT02 is engineered for seamless integration, featuring precise signal transmission pathways, high-grade materials for durability, and compatibility with legacy and modern ABB control architectures. It is frequently employed in process control systems, DCS configurations, and manufacturing automation lines where dependable control and data integrity are essential.

Product Specifications

| Parameter | Specification |

|---|---|

| Product Name | ABB 88VT02 Printed Circuit Board |

| Product Code | GJR2363900R1000 |

| Product Type | PCB (Control Logic / I/O Interface) |

| System Compatibility | Advant Controller 31 / ABB Automation Systems |

| Main Function | Signal processing, I/O interfacing, system logic |

| PCB Layers | Multi-layer design (4–6 layers typical) |

| Operating Voltage Range | 5V / 12V DC (dependent on application) |

| Power Consumption | < 4 W (typical) |

| Interface Type | Backplane / Connector edge slot |

| Operating Temperature Range | 0°C to +60°C |

| Storage Temperature Range | -25°C to +70°C |

| Humidity Tolerance | 5%–95%, non-condensing |

| Mounting | Rack-mount or Backplane Slot |

| PCB Material | FR-4 industrial-grade epoxy glass |

| Dimensions (W x H x D) | 160 x 100 x 20 mm |

| Weight | 0.2 kg |

| Compliance | CE, RoHS |

| Maintainability | Field-replaceable with diagnostics |

Product Applications

The ABB 88VT02 PCB is deployed in a wide array of industrial and automation systems, supporting mission-critical control operations. Typical applications include:

-

Process Control Systems – Interfaces with field instruments and sensors for real-time control and monitoring.

-

Factory Automation – Used in programmable logic controller (PLC) systems for discrete and batch processes.

-

Chemical and Petrochemical Plants – Supports robust and stable process operations in hazardous environments.

-

Power Generation Facilities – Functions within turbine control and auxiliary management systems.

-

Water Treatment Plants – Manages control tasks related to filtration, chemical dosing, and pumping systems.

-

Metals and Mining – Handles distributed I/O and logic control in harsh, vibration-intensive operations.

Product Advantages

-

Highly Reliable Construction

The multi-layered PCB design ensures optimal signal isolation and minimal interference, reducing noise in complex control systems. -

Compact, Efficient Design

With a small footprint, the 88VT02 conserves space within rack-mounted enclosures while still delivering full functionality. -

ABB System Integration

Built specifically for ABB platforms, allowing plug-and-play operation within Advant Controller frameworks. -

Field-Replacement Capability

Designed for easy swap-out with minimal downtime, aiding rapid maintenance and reducing Mean Time to Repair (MTTR). -

Long Lifecycle Support

ABB’s long-term support programs ensure availability of replacements and documentation for extended system life. -

Proven Field Performance

Deployed across thousands of installations globally with a solid track record of durability and precision.

Frequently Asked Questions (FAQ)

1.What is the primary function of the 88VT02 PCB within the ABB control system?

The 88VT02 board typically functions as a signal conditioning or interface module between I/O devices and the central processor in ABB control systems. It ensures accurate transmission of control or monitoring signals across the system.

20Does the 88VT02 require calibration before commissioning?

No, this board does not require field calibration. It is designed for direct plug-and-play operation within the correct ABB rack environment, assuming system configuration is correctly set.

3.What type of environmental protections does the 88VT02 include?

The board itself is protected by a conformal coating to resist dust and humidity. However, it must be housed within an industrial-grade enclosure for proper operation in harsh environments.

4.How should the board be stored if not installed immediately?

The 88VT02 must be stored in anti-static, moisture-proof packaging and kept in a climate-controlled environment to prevent electrostatic damage and oxidation of contacts.

5.Can the 88VT02 operate in systems with redundant control architecture?

Yes, the 88VT02 can be deployed in systems that utilize redundancy, as long as it is properly assigned to its channel or segment and synchronized through the main controller’s logic.

6.What kind of connector interface does the 88VT02 board utilize?

It typically uses card-edge or multi-pin backplane connectors designed to slot directly into a proprietary ABB rack. No additional cabling is required on the board itself.

7.Are there known compatibility limitations with certain firmware versions of ABB controllers?

Compatibility is generally stable, but it’s always best practice to verify the hardware compatibility list (HCL) or contact ABB technical support when integrating with newer-generation controllers.

8.How can I verify that the board is receiving and transmitting data correctly?

System diagnostics via the main HMI or engineering station can verify input/output activity. Some setups may also use loopback tests or signal simulation for more rigorous checks.

9.Is there a way to test the 88VT02 board outside the control rack?

No, it must be tested within a compatible ABB rack or simulation station. Bench testing is not supported unless using proprietary ABB diagnostic tools.

10.What maintenance does the board require during normal system operation?

The 88VT02 is maintenance-free under normal conditions. However, routine visual inspection for dust accumulation, corrosion, or bent connectors during scheduled plant shutdowns is recommended.

Related Models (Same Series or Functional Range)

| Model | Description | System Compatibility | Dimensions (mm) | Weight |

|---|---|---|---|---|

| ABB 88VU01 | Voltage Measurement PCB for Advant systems | Advant Controller 31 | 160 x 100 x 20 | 210 g |

| ABB 88YA01 | Digital Output Interface Board | Advant DCS/31 systems | 160 x 100 x 20 | 200 g |

| ABB 88FG01 | Analog Signal Processing PCB | ABB I/O rack systems | 160 x 100 x 22 | 220 g |

| ABB 88TV01 | Timing and Synchronization Control Board | Advant Process Systems | 165 x 105 x 20 | 230 g |

| ABB 88UR01 | Redundant Logic Interface Module | AC 31/Advant compatible | 160 x 100 x 20 | 215 g |

| ABB 88SL02 | Safety Loop Signal Board | ABB safety-critical systems | 170 x 110 x 25 | 250 g |

Popular ABB Models (Cross-Platform and Widely Used)

| Model | Description | Application | Dimensions (mm) | Weight |

|---|---|---|---|---|

| ABB PM866K02 | CPU unit for AC800M with redundancy support | DCS / PLC applications | 170 x 140 x 55 | 620 g |

| ABB REF620 | Feeder Protection Relay | Power transmission and grids | 230 x 280 x 100 | 1.9 kg |

| ABB CI854AK01 | PROFIBUS communication interface | AC800M / S800 I/O systems | 115 x 145 x 50 | 320 g |

| ABB PM572 ETH | Compact CPU with built-in Ethernet | Small-scale industrial control | 125 x 140 x 60 | 400 g |

| ABB AI835A | Analog Input Module for S800 I/O | Temperature and signal monitoring | 110 x 120 x 35 | 300 g |

| ABB CP665 | HMI with 10.4″ TFT display | Human-machine interface | 260 x 190 x 55 | 1.4 kg |

Excellent PLC

Excellent PLC