| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

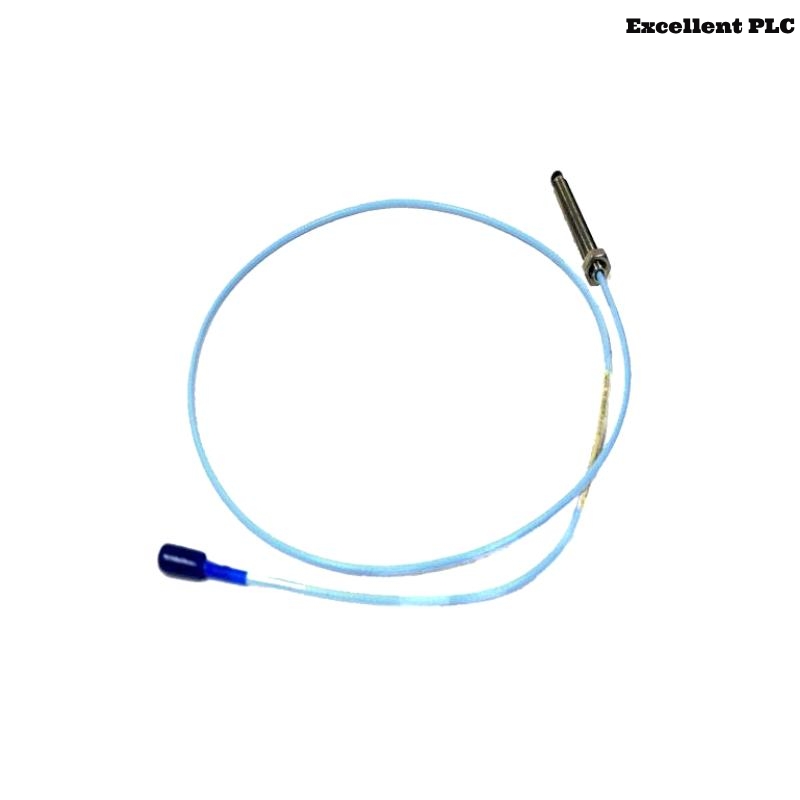

The Bently Nevada 330101-00-45-05-02-00 is a part of the 3300 XL 8mm Proximity Transducer System, a globally recognized standard for non-contact shaft vibration and position monitoring in rotating machinery. This particular model includes a 0.5 meter unarmored probe and is designed to deliver accurate, high-resolution displacement measurements using eddy current sensing technology.

Specifically engineered to operate reliably in demanding industrial environments such as turbines, compressors, motors, and pumps, this probe plays a critical role in predictive maintenance and machinery protection strategies. Combined with a matching extension cable and Proximitor® sensor, it forms a complete system with industry-proven performance.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | 330101-00-45-05-02-00 |

| Series | 3300 XL 8mm Proximity Transducer System |

| Measurement Principle | Eddy Current, Non-contact displacement measurement |

| Probe Tip Diameter | 8 mm |

| Thread Size | 3/8-24 UNF-2A (forward mount) |

| Total Length | 0.5 meter |

| Cable Type | Unarmored |

| Connector | ClickLoc Stainless Steel |

| Target Material | AISI 4140 Steel (standard calibration) |

| Sensitivity | 200 mV/mil (7.87 mV/μm) |

| Linear Range | 0.5 to 2.0 mm (20 to 80 mils) |

| Total System Length | Specified by probe, extension, and proximitor combination |

| Frequency Response | 0 to 10 kHz (-3dB, system dependent) |

| Operating Temperature Range | -35°C to +177°C (-31°F to +350°F) |

| Storage Temperature Range | -51°C to +177°C (-60°F to +350°F) |

| Housing Material | Stainless Steel |

| Ingress Protection | IP65 (with proper sealing and installation) |

| Weight | 0.323 kg |

Product Applications

The Bently Nevada 330101-00-45-05-02-00 is designed for real-time condition monitoring in high-value rotating equipment. Its most common industrial applications include:

-

Steam and Gas Turbines – For radial and axial shaft position monitoring to detect early-stage wear, rotor bow, or thermal growth.

-

Compressors (Centrifugal & Axial) – Monitoring rotor vibration and alignment issues to prevent unplanned shutdowns.

-

Industrial Motors and Generators – Ensures that shaft deflection does not cause damage to internal components.

-

Large Pumps – Protects against seal failures by monitoring shaft movement.

-

Gearboxes – Enables detection of gear mesh issues, misalignment, and bearing faults.

-

Fans and Blowers – Tracks imbalance and vibration trends to optimize uptime and reduce maintenance costs.

Product Advantages

-

Non-contact Measurement: Prevents mechanical wear, suitable for continuous long-term use.

-

High Precision: Delivers accurate and linear measurements across a broad temperature range.

-

Robust Construction: Stainless steel housing ensures durability in harsh and hazardous industrial environments.

-

Seamless Integration: Fully compatible with 3300 XL system including extension cables and Proximitor sensors.

-

ClickLoc Connector: Ensures reliable and secure connections resistant to vibration-induced loosening.

-

Broad Compatibility: Optimized for use with a variety of machinery and materials (standard target: AISI 4140).

-

Temperature Resilience: Operates effectively across extreme ambient and process temperatures.

-

Fast Response Time: Capable of monitoring fast dynamic changes in shaft behavior.

-

Low Maintenance: Designed for ease of installation, calibration, and long maintenance intervals.

-

Global Standard: Accepted and trusted in industries worldwide for machine protection systems.

Frequently Asked Questions (FAQ)

-

What is the purpose of the 330101-00-45-05-02-00 probe?

It measures the proximity (distance) between the probe tip and a conductive shaft to monitor vibration and position in rotating machinery. -

Can this probe be used in high-temperature environments?

Yes, it supports operation up to +177°C, making it suitable for many high-temperature industrial applications. -

Does it require a matching proximitor and extension cable?

Yes, this probe is part of a three-component system and must be paired with specific 3300 XL cables and Proximitor sensors. -

Is this model suitable for forward mounting only?

Correct, this variant uses a forward mount configuration and is threaded for installation from the machine exterior. -

What materials can it sense?

Standard calibration is for AISI 4140 steel, but custom calibrations are possible for other conductive targets. -

Is the cable replaceable or field-repairable?

No, the probe cable is fixed. If damaged, the entire probe needs replacement. -

Can the system detect bearing failures?

Indirectly, yes—by measuring shaft vibration, it can identify signs of bearing wear or failure. -

What’s the minimum measurable distance?

The linear operating range begins at 0.5 mm from the target surface. -

Is it compatible with older Bently Nevada systems?

It is optimized for the 3300 XL system and may not be compatible with legacy systems like the 7200 series. -

How do I ensure proper sealing for IP65 protection?

Use approved gaskets, sealing compounds, and proper cable glands as per Bently Nevada’s installation guidelines.

Related Models from the Same Series

| Model Number | Cable Length | Mount Style | Connector Type | Notes |

|---|---|---|---|---|

| 330101-00-40-05-02-00 | 40 inches | Forward Mount | ClickLoc | Similar functionality, shorter cable |

| 330101-00-50-05-02-00 | 50 inches | Forward Mount | ClickLoc | For extended reach installations |

| 330101-00-60-05-02-00 | 60 inches | Forward Mount | ClickLoc | Used in large-frame equipment |

| 330101-00-45-10-02-00 | 45 inches | Reverse Mount | ClickLoc | Alternate mounting configuration |

| 330104-00-08-10-02-00 | 8 meters | Armored Probe | ClickLoc | Harsh environments, extended range |

| 330103-00-08-10-02-00 | 8 meters | Extension Cable | N/A | For probe-to-proximitor connection |

Popular Bently Nevada Models (Same Brand)

| Model Number | Product Type | Function | Key Feature |

|---|---|---|---|

| 3500/42M | Proximitor Monitor | Vibration Monitoring | 4-channel system with buffered output |

| 3500/25 | Keyphasor Module | Speed and Phase Measurement | Dual-channel, essential for rotating machines |

| 3500/22M | Transient Data Interface | Data Communication Interface | Ethernet support, transient analysis |

| 330103-00-06-10-02-00 | Extension Cable (6m) | Probe System Interconnect | Essential for system matching |

| 7200-50 Series | Proximity Transducer | Displacement Monitoring | Legacy system, durable and proven |

| 330104-00-05-10-02-00 | 5-meter Proximity Probe | Vibration and Position Sensing | Armored cable for rugged installations |

Excellent PLC

Excellent PLC