| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

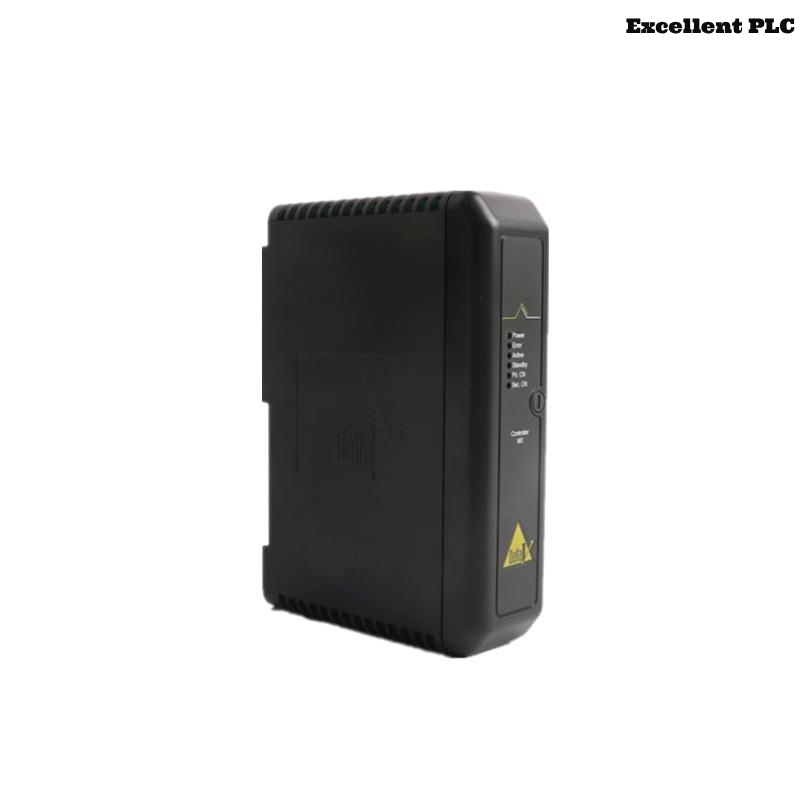

The Emerson KJ2005X1-BA1 MX Controller is a high-performance control module engineered for use within the DeltaV™ distributed control system (DCS). As part of Emerson’s legacy of dependable automation solutions, this controller provides reliable and scalable control for process automation applications, enabling industries to achieve superior process safety, optimization, and operational efficiency.

This module is designed to operate as the central control unit within a DeltaV system, capable of executing complex process control strategies and managing large volumes of input/output (I/O) data. With real-time diagnostics, robust cybersecurity features, and seamless integration capabilities, the KJ2005X1-BA1 ensures efficient control under demanding industrial environments.

Product Specifications

| Parameter | Description |

|---|---|

| Product Name | MX Controller |

| Model Number | KJ2005X1-BA1 |

| Manufacturer | Emerson Process Management |

| System Compatibility | DeltaV™ DCS |

| Processor Type | 32-bit Motorola PowerPC |

| Memory | 64 MB Flash / 32 MB DRAM |

| I/O Capacity | Supports up to 30,000 I/O |

| Communication Protocols | DeltaV Proprietary Protocol, Ethernet, OPC |

| Redundancy Support | Yes (when configured with redundant controller pair) |

| Execution Speed | High-speed deterministic execution |

| Status Indicators | LED indicators for power, fault, and active state |

| Operating Temperature | -40°C to +70°C (-40°F to +158°F) |

| Storage Temperature | -40°C to +85°C (-40°F to +185°F) |

| Humidity Range | 5% to 95% non-condensing |

| Power Consumption | Less than 5 W |

| Mounting | DIN Rail / Chassis-based |

| Dimensions (H x W x D) | 120 x 102 x 55 mm |

| Weight | 0.272 kg |

| Certifications | CE, CSA, ATEX Zone 2, UL, GOST, IECEx |

| Firmware Upgradeability | Supported via DeltaV system |

| Diagnostics | Advanced self-diagnostics and system health monitoring |

Product Applications

-

Oil and Gas Processing: Controls upstream, midstream, and downstream operations including refining, pipeline control, and LNG processing.

-

Power Generation: Manages turbine control, auxiliary systems, and balance of plant (BOP) operations.

-

Chemical and Petrochemical Industries: Ensures precise control of reactors, batch processes, and hazardous environments.

-

Pharmaceutical Manufacturing: Supports GMP-compliant control strategies for batch automation.

-

Food and Beverage Production: Delivers consistent and regulated control for hygienic process systems.

-

Water and Wastewater Treatment: Monitors and adjusts critical flow, pressure, and treatment parameters in real time.

-

Pulp and Paper Mills: Ensures reliable control of continuous production lines and energy-efficient process loops.

Product Advantages

-

High Availability and Reliability: Built for mission-critical applications with support for redundancy and robust fault tolerance.

-

Real-Time Performance: Delivers deterministic, high-speed execution for time-sensitive operations.

-

Flexible Integration: Seamlessly integrates with third-party systems, legacy protocols, and digital fieldbus.

-

Cybersecurity Built-in: Includes encryption support, access control, and secure firmware updates.

-

Compact Form Factor: Ideal for space-constrained installations while maintaining scalability.

-

Field-Proven Platform: Backed by extensive deployment in multiple industrial sectors worldwide.

-

Simplified Maintenance: Advanced diagnostics and easy firmware upgrades reduce operational overhead.

-

Energy Efficiency: Low power consumption supports energy-conscious automation environments.

FAQ

-

What is the primary function of the KJ2005X1-BA1 controller?

It serves as the core processing unit within a DeltaV system, executing control logic and managing I/O communications. -

Is the KJ2005X1-BA1 compatible with redundant configurations?

Yes, it supports redundant controller pairing to ensure uninterrupted operation. -

Can the controller be used in hazardous environments?

Absolutely, it holds certifications like ATEX Zone 2 and IECEx for hazardous area deployment. -

Does this controller support third-party communication protocols?

It primarily uses DeltaV protocols, but integration via OPC and Ethernet is supported. -

What type of processor is used in the MX Controller?

It uses a 32-bit Motorola PowerPC processor for high-speed execution. -

What happens in case of a controller failure?

If configured with redundancy, the backup controller takes over automatically without process interruption. -

Can the firmware be updated remotely?

Yes, firmware can be securely updated through the DeltaV system interface. -

Is there a built-in diagnostic feature?

Yes, the controller includes real-time system health and diagnostics capabilities. -

What is the maximum I/O capacity supported?

The controller supports managing up to 30,000 I/O points within a fully scaled system. -

What kind of mounting is required?

It can be DIN rail-mounted or placed in a compatible DeltaV chassis.

Related Models from the Same Series or Family

| Model Number | Description | System Compatibility | Redundancy | Weight |

|---|---|---|---|---|

| KJ2005X1-BA2 | Enhanced version of MX controller | DeltaV™ | Yes | 0.65 kg |

| KJ2003X1-BB1 | Classic controller with standard performance | DeltaV™ | Optional | 0.55 kg |

| KJ3002X1-BB1 | Redundant I/O controller | DeltaV™ | Yes | 0.62 kg |

| KJ4010X1-BG1 | Foundation Fieldbus controller | DeltaV™ | No | 0.58 kg |

| KJ3222X1-BA1 | I/O Subsystem controller | DeltaV™ | Yes | 0.57 kg |

| KJ3241X1-BA1 | Profibus DP interface module | DeltaV™ | No | 0.50 kg |

Popular Emerson Models (Same Brand, Various Systems)

| Model Number | Description | Application | System | Weight |

|---|---|---|---|---|

| AMS Trex 375 | Field communicator for HART & Foundation | Field device management | AMS | 0.85 kg |

| ROC800-Series | Remote Operations Controller | Oil & Gas SCADA | ROC800 | 1.20 kg |

| DeltaV CHARM I/O | Modular I/O subsystem with CHARM tech | Process automation | DeltaV | 0.90 kg |

| Ovation Controller | Power plant control platform | Power & Water | Ovation™ | 1.10 kg |

| Emerson PACSystem RX3i | Programmable automation controller | Discrete and hybrid control | PACSystems | 1.25 kg |

| DeltaV M-Series | Modular control system with legacy support | Batch and continuous process | DeltaV M-Series | 1.00 kg |

Excellent PLC

Excellent PLC