| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

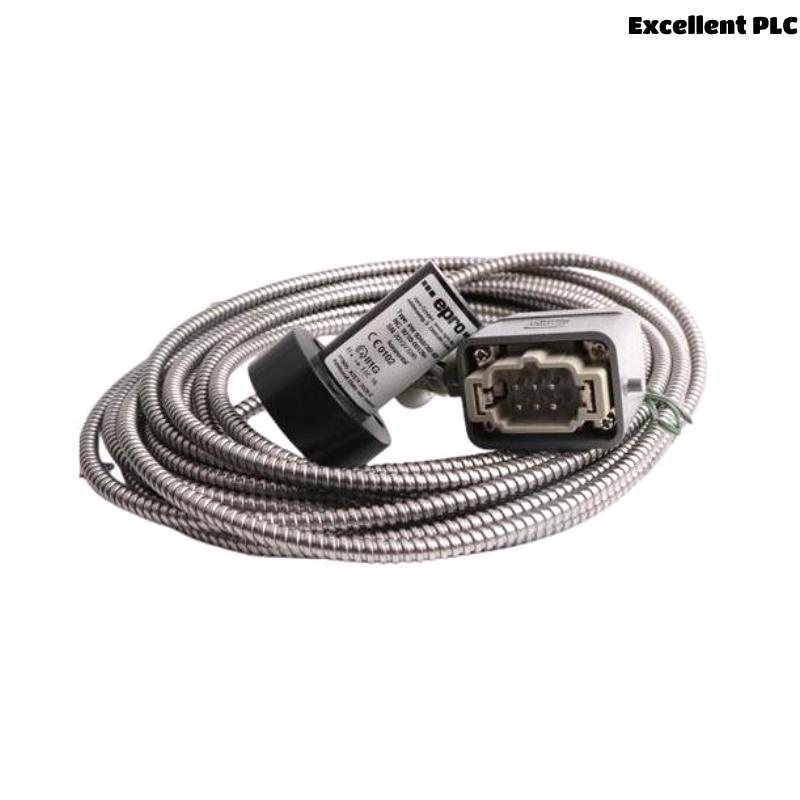

The Epro PR9268/602-000 is a robust and reliable electrodynamic velocity sensor designed specifically for vibration monitoring in industrial rotating machinery. This sensor is part of the trusted PR9268 series by Epro, a brand known for high-quality condition monitoring solutions tailored for demanding environments.

As a velocity transducer, the PR9268/602-000 converts mechanical vibrations directly into an electrical voltage signal, which is proportional to the velocity of the movement. The rugged design ensures long-term performance even under severe operating conditions such as those found in power generation, steel processing, pulp & paper, and petrochemical industries.

This sensor is suitable for both OEM installations and retrofit projects where high sensitivity and broad frequency response are essential. It integrates seamlessly with monitoring systems like the Epro MMS series or other industrial vibration measurement platforms.

Product Specifications

| Parameter | Description |

|---|---|

| Model | PR9268/602-000 |

| Sensor Type | Electrodynamic Velocity Sensor |

| Measuring Range | 0 to 50 mm/s RMS (typical) |

| Frequency Range | 10 to 1,000 Hz (±3 dB) |

| Sensitivity | 28.5 mV/mm/s ±5% (at 80 Hz, 22°C) |

| Output Signal | Analog Voltage (proportional to velocity) |

| Internal Damping | < 5% |

| Mounting | M8 or M10 stud mount |

| Operating Temperature Range | -35°C to +120°C |

| Shock Resistance | Up to 1000 g |

| Housing Material | Stainless Steel |

| Protection Class | IP67 (dust and water tight) |

| Connector Type | MIL-C-5015, 2-pin or integral cable |

| Weight | 1.05 kg |

| Dimensions | 78 × 58 mm |

Product Applications

The PR9268/602-000 sensor is widely used in condition monitoring and predictive maintenance programs for rotating equipment. Common applications include:

-

Gas and Steam Turbines

-

Centrifugal Compressors

-

Pumps and Blowers

-

Motors and Generators

-

Industrial Fans

-

Rolling Mills and Conveyors

Its ability to detect low-frequency vibration makes it highly suitable for identifying issues like misalignment, imbalance, looseness, and bearing faults at an early stage, helping to prevent costly machinery failures and unplanned shutdowns.

Product Advantages

-

High Sensitivity and Accuracy

Offers excellent signal quality for precise vibration velocity measurements, even at low frequencies. -

Wide Frequency Response

Ensures effective detection of a broad range of mechanical faults. -

Rugged and Reliable Design

Stainless steel housing and IP67 protection allow for deployment in harsh industrial environments. -

Versatile Mounting Options

Compatible with both M8 and M10 threads for flexible integration into various machine configurations. -

Low Maintenance and Long Life

The non-electronic, passive design minimizes maintenance needs and improves MTBF (Mean Time Between Failures). -

Compatibility with Epro Monitoring Systems

Seamlessly integrates with Epro’s MMS6000 and MMS8000 systems as well as other third-party monitoring solutions.

Frequently Asked Questions (FAQ)

-

What is the primary function of the PR9268/602-000 sensor?

It measures vibration velocity to detect potential mechanical faults in rotating equipment. -

Is this sensor suitable for hazardous areas?

The PR9268/602-000 is available in ATEX-certified variants upon request for hazardous environments. -

Can I use this sensor in high-moisture or dusty areas?

Yes, it has an IP67 rating for water and dust ingress protection. -

What type of signal does this sensor produce?

It generates an analog voltage signal proportional to the vibration velocity. -

Is the sensor sensitive to installation direction?

Yes, it should be mounted perpendicularly to the vibration source for optimal performance. -

Does this sensor require power supply?

No external power is required; it is a passive sensor based on electrodynamic principles. -

Can it detect low-frequency vibrations?

Yes, with a frequency response starting from 10 Hz, it is well-suited for detecting low-frequency faults. -

How is it typically mounted?

Using M8 or M10 studs, either horizontally or vertically, depending on application needs. -

Is this sensor compatible with PLCs or DCS systems?

Yes, via intermediate signal conditioners or monitoring modules, it can feed into DCS/PLC systems. -

What are the calibration requirements?

While it is factory-calibrated, annual calibration checks are recommended for critical applications.

Related Models from the Same Series

| Model | Sensitivity | Frequency Range | Mounting Type | Output Type |

|---|---|---|---|---|

| PR9268/600-000 | 28.5 mV/mm/s | 10 – 1,000 Hz | M10 Stud | Analog |

| PR9268/601-000 | 28.5 mV/mm/s | 10 – 1,000 Hz | M8 Stud | Analog |

| PR9268/603-000 | 100 mV/in/s | 12 – 1,000 Hz | M10 Stud | Analog |

| PR9268/604-000 | 10 mV/mm/s | 5 – 500 Hz | M8 Stud | Analog |

| PR9268/605-000 | 45 mV/mm/s | 15 – 900 Hz | Flange Mount | Analog |

| PR9268/606-000 | 28.5 mV/mm/s | 10 – 1,000 Hz | Magnetic Base | Analog |

Popular Models from the Same Brand (Epro)

| Model | Product Type | Application Area | Output Signal |

|---|---|---|---|

| PR6423/002-030 | Eddy Current Sensor | Shaft Vibration Monitoring | 4–20 mA / Voltage |

| CON021 | Sensor Connection Interface | PR6423 Signal Conditioning | Analog |

| MMS6312 | Monitoring Module | Vibration & Speed | Digital / Relay |

| MMS3120/022-100 | Signal Conditioner Module | Vibration Monitoring | Digital / Analog |

| PR6424/010-000 | Proximity Probe System | Axial Position Monitoring | Voltage |

| PR9350/02 | Speed Sensor | Overspeed Detection | TTL / Frequency |

Excellent PLC

Excellent PLC