| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

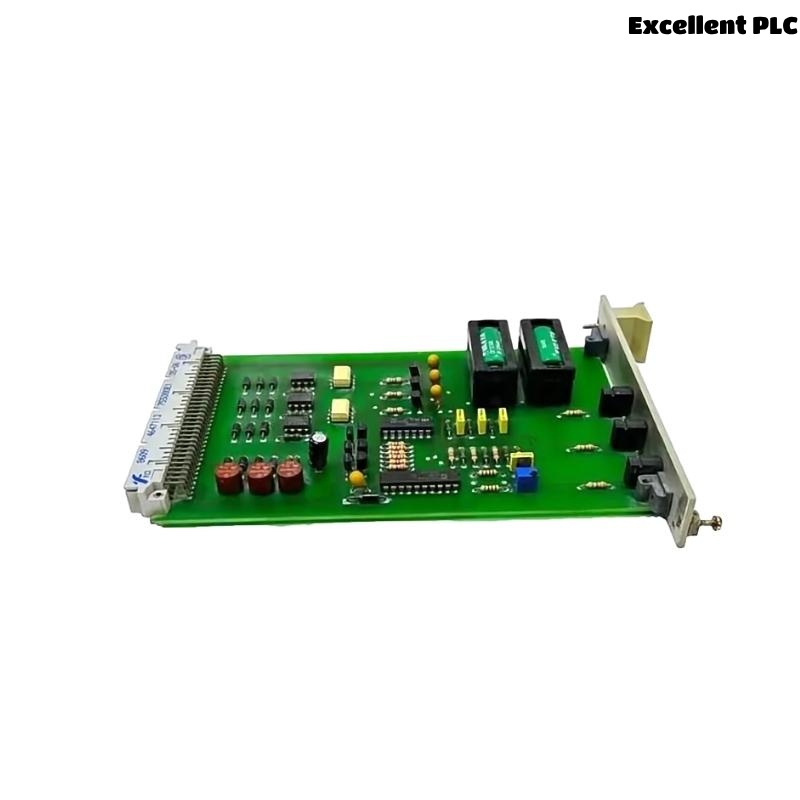

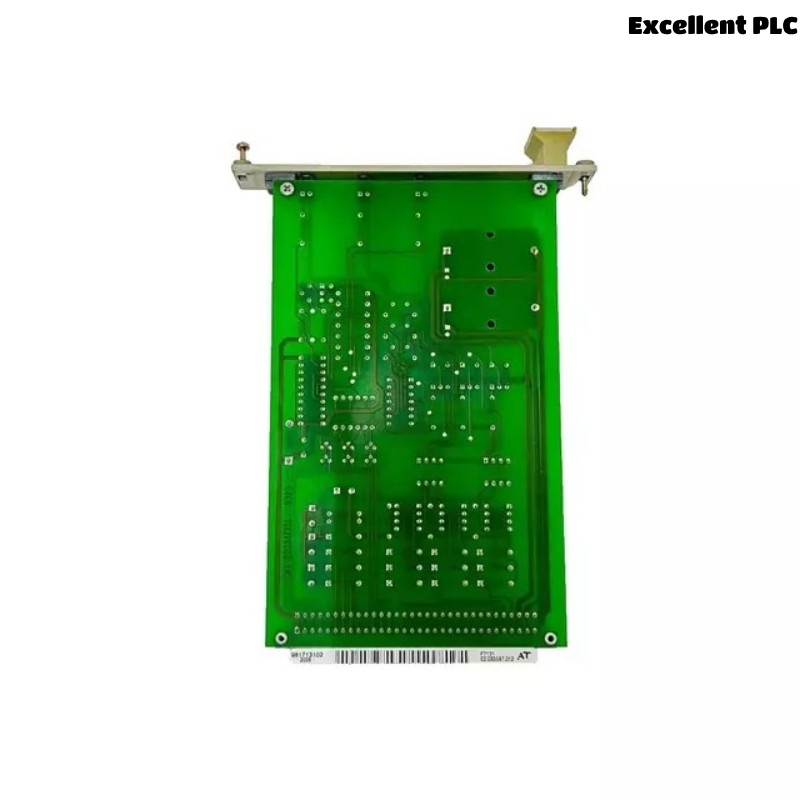

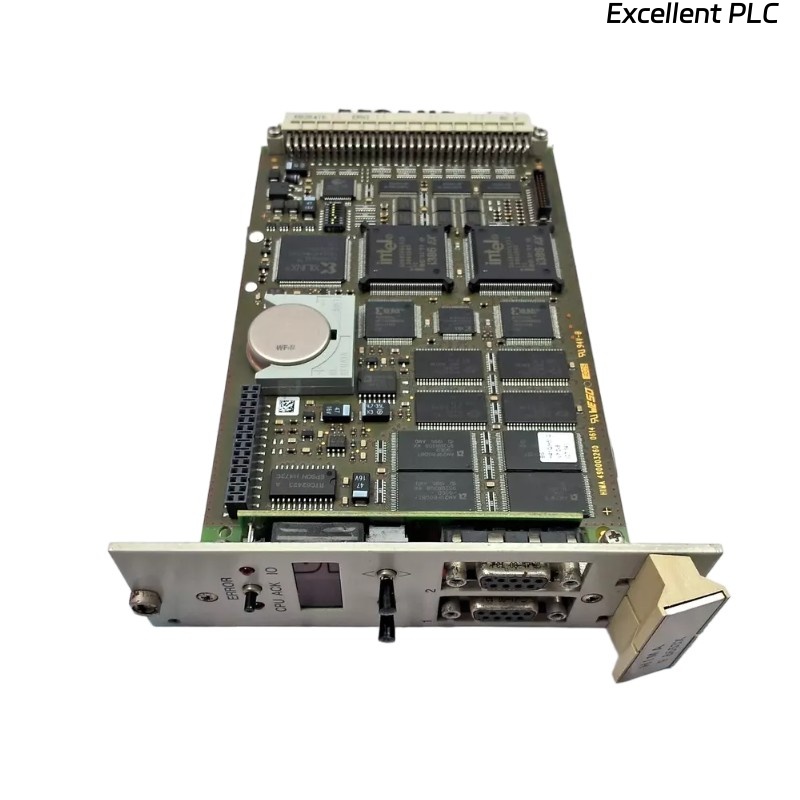

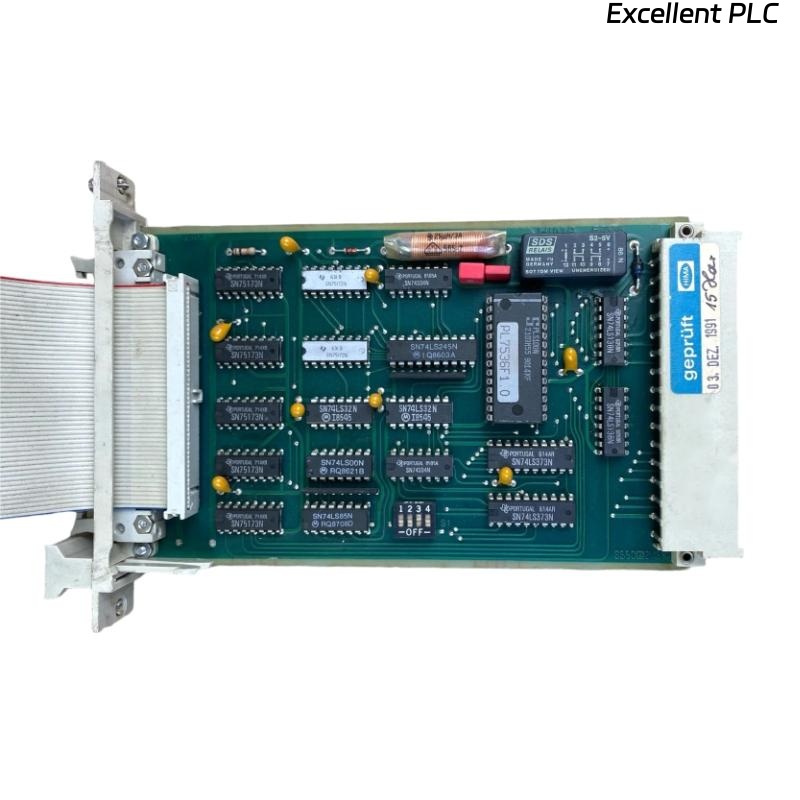

Product Introduction

The HIMA F7131 is a specialized power supply monitoring unit designed for critical industrial safety systems that require continuous and reliable power supply monitoring. This product integrates buffer batteries, which ensure that in the event of power disruptions or failures, the monitoring system maintains uninterrupted operation. The unit is primarily employed in safety-instrumented systems (SIS) and control environments where power reliability is paramount to avoid hazardous conditions or operational interruptions.

The F7131 is engineered to monitor the status and health of the power supply while managing the charging and discharging cycles of the buffer batteries. This guarantees that backup power is available instantly when needed. By providing detailed diagnostics and alarms, the device allows timely maintenance actions and enhances overall system availability and safety integrity.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | HIMA F7131 |

| Function | Power Supply Monitoring with Buffer Batteries |

| Input Voltage Range | 24 V DC nominal |

| Output Voltage | 24 V DC (regulated) |

| Battery Type | Lead-acid or NiMH buffer batteries (configurable) |

| Monitoring Capabilities | Voltage, current, battery status, charger status, fault detection |

| Communication Interface | PROFIBUS DP / Modbus TCP (optional) |

| Operating Temperature | -20 °C to +70 °C |

| Storage Temperature | -40 °C to +85 °C |

| Humidity | 5% to 95% (non-condensing) |

| Mounting | DIN rail |

| Space requirement | 4 TE |

| Weight | 0.19 kg |

| Certifications | SIL 3 certified, ATEX, IECEx |

Product Applications

-

Industrial Safety Instrumented Systems (SIS): Ensures power supply reliability to emergency shutdown systems.

-

Process Automation: Power monitoring in chemical, petrochemical, and refining plants.

-

Power Plants: Supports continuous monitoring of power supply for turbine control and safety systems.

-

Oil & Gas: Reliable power backup monitoring in hazardous and remote environments.

-

Transportation Systems: Monitoring buffer battery health in railway signaling and control.

-

Manufacturing: Continuous power supply supervision to prevent downtime in critical automation processes.

Product Advantages

-

High Reliability: Designed for mission-critical environments with SIL 3 certification ensuring high safety standards.

-

Buffer Battery Integration: Real-time monitoring and management of buffer batteries extend power availability during outages.

-

Comprehensive Diagnostics: Early fault detection and status monitoring reduce maintenance costs and improve uptime.

-

Flexible Communication: Supports integration into various industrial networks for seamless data exchange.

-

Robust Design: Withstands harsh industrial environments, wide temperature range, and certified for explosive atmospheres.

-

Compact Size: Small footprint for easy installation within existing control cabinets.

-

User-Friendly Interface: Simple configuration and clear visual status indicators facilitate fast commissioning and troubleshooting.

Frequently Asked Questions (FAQ)

-

What types of buffer batteries are compatible with the HIMA F7131?

The unit supports lead-acid and NiMH batteries, configurable based on customer requirements. -

Can the F7131 operate in hazardous environments?

Yes, it is certified for ATEX and IECEx zones, making it suitable for explosive atmospheres. -

What is the typical lifespan of the buffer batteries monitored by this device?

Battery life depends on usage and environmental conditions, but typically ranges between 3-5 years with proper maintenance. -

Is remote monitoring supported?

Yes, the unit can interface with PROFIBUS DP or Modbus TCP for remote diagnostics and control. -

How does the device alert operators to power or battery faults?

It provides both visual indicators and communication alarms to notify operators immediately. -

What is the installation process like?

The F7131 mounts on a standard DIN rail and comes with detailed installation manuals for quick setup. -

Can this device be integrated into existing safety systems?

Yes, it is designed to integrate seamlessly with HIMA and third-party safety instrumented systems. -

What maintenance is required?

Regular battery checks and occasional calibration are recommended, supported by the device’s diagnostic reports. -

Does it support redundant power supply monitoring?

Yes, configurations can include redundant power supplies and battery monitoring to increase reliability. -

What are the weight of the device?

The unit weighs about 0.19 kg.

Recommended Related Models

| Model Number | Description | Key Feature |

|---|---|---|

| HIMA F7130 | Power Supply Monitoring (without batteries) | Basic power monitoring unit |

| HIMA F7132 | Power Supply Monitoring with Extended Battery Backup | Longer battery runtime |

| HIMA F7135 | Advanced Battery Management Module | Enhanced diagnostics and control |

| HIMA F7121 | Safety Power Supply Module | Integrated safety-rated power unit |

| HIMA F7140 | UPS Monitoring Module | Uninterruptible power supply monitoring |

| HIMA F7150 | Power Supply & Battery Health Analytics | Advanced analytics and reporting |

Popular Models from HIMA Brand

| Model Number | Description | Typical Use |

|---|---|---|

| HIMA F7200 | Safety PLC with High Availability | Safety automation controller |

| HIMA F7201 | Compact Safety Controller | Small to medium safety applications |

| HIMA F7241 | Modular Safety System | Large-scale safety system control |

| HIMA F7206 | Safety I/O Module | Flexible I/O integration |

| HIMA F7230 | Wireless Safety Communication Module | Safety communication over wireless |

| HIMA F7210 | Safety Network Module | Network redundancy and diagnostics |

Excellent PLC

Excellent PLC