| Company Information | ||||||||

| sales@xmjzjsgs.com | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

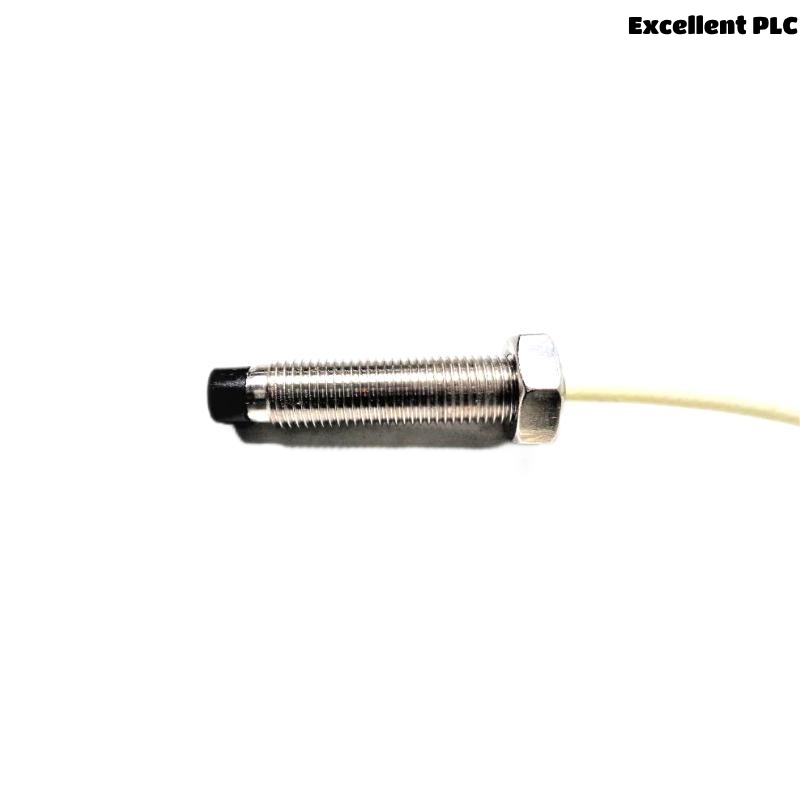

The Bently Nevada 21504-000-016-10-02 is a high-precision, non-contact proximity probe designed for accurate measurement of shaft position and vibration in rotating machinery. As part of the 7200 Series, this 8 mm reverse mount probe is engineered for applications requiring reliable performance in challenging industrial environments. Its reverse mount configuration allows for installation in tight spaces, making it ideal for machinery with limited access.

Manufactured by Bently Nevada, a division of Baker Hughes, this probe is compatible with the 7200 Proximity Transducer System, ensuring seamless integration into existing monitoring setups. The probe’s robust construction and precise measurement capabilities make it a preferred choice for condition monitoring and predictive maintenance programs.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | 21504-000-016-10-02 |

| Series | 7200 Series |

| Probe Type | Reverse Mount Proximity Probe |

| Tip Diameter | 8 mm |

| Thread Size | 3/8-24 UNF |

| Unthreaded Length | 0.0 inches |

| Connector Type | Miniature male coaxial connector |

| Lead Armor | Not included |

| Input Power | -17.5 VDC to -26 VDC at 12 mA max consumption |

| Output Calibrated Range | 80 mils (2.0 mm), starting at approximately 10 mils (0.25 mm) from the probe face |

| Operating Temperature | -51°C to +177°C (-60°F to +351°F) |

| Storage Temperature | -51°C to +177°C (-60°F to +351°F) |

| Weight | 0.09 kg |

| Compliance | RoHS |

Applications

The Bently Nevada 21504-000-016-10-02 probe is designed for use in a variety of industrial applications where precise, non-contact measurement of shaft position and vibration is critical. Typical applications include:

-

Gas and Steam Turbines: Monitoring shaft vibration and position to prevent mechanical failures.

-

Compressors: Detecting imbalance, misalignment, and bearing wear.

-

Pumps: Ensuring optimal performance and early detection of mechanical issues.

-

Electric Motors: Monitoring for shaft misalignment and vibration anomalies.

-

Generators: Ensuring stability and performance through continuous monitoring.

-

Centrifuges: Detecting imbalance and mechanical wear.

Its reverse mount design allows for installation in confined spaces, making it suitable for equipment with limited access.

Advantages

-

High Precision: Provides accurate measurements of shaft position and vibration, essential for condition monitoring.

-

Reverse Mount Design: Facilitates installation in tight or confined spaces without compromising measurement accuracy.

-

Robust Construction: Designed to withstand harsh industrial environments, including extreme temperatures and mechanical stress.

-

Wide Operating Temperature Range: Suitable for applications with temperature variations from -51°C to +177°C.

-

Compatibility: Integrates seamlessly with Bently Nevada’s 7200 Proximity Transducer System and other monitoring equipment.

-

Ease of Installation: Standard thread size and connector type simplify the installation process.

-

Maintenance-Friendly: Durable design reduces the need for frequent maintenance and calibration.

Frequently Asked Questions (FAQ)

1. What is the primary function of the 21504-000-016-10-02 probe?

It measures the static and dynamic distance between the probe tip and the observed object, typically used for monitoring shaft position and vibration in rotating machinery.

2. Can this probe be used in high-temperature environments?

Yes, it operates effectively in temperatures ranging from -51°C to +177°C, making it suitable for high-temperature applications.

3. Is the probe compatible with other Bently Nevada systems?

Yes, it is designed to work with Bently Nevada’s 7200 Proximity Transducer System and is compatible with other monitoring equipment.

4. What is the significance of the reverse mount design?

The reverse mount design allows for installation in areas with limited access, facilitating maintenance and reducing installation complexity.

5. Does the probe come with armored cable?

No, this specific model does not include lead armor. However, armored versions are available for applications requiring additional protection.

6. What is the output range of the probe?

It has an output calibrated range of 80 mils (2.0 mm), starting at approximately 10 mils (0.25 mm) from the probe face.

7. What type of connector does the probe use?

It uses a miniature male coaxial connector, standard for Bently Nevada probes.

8. Is the probe RoHS compliant?

Yes, it complies with the Restriction of Hazardous Substances (RoHS) directive.

9. What is the weight of the probe?

The probe weighs 0.09 kg.

10. Where is the probe manufactured?

It is manufactured in the United States, ensuring adherence to high-quality standards.

Related Models

| Model Number | Description | Mount Type | Tip Diameter |

|---|---|---|---|

| 21504-00-08-05-02 | 8 mm Standard Mount Proximity Probe | Standard | 8 mm |

| 21504-00-24-10-02 | 8 mm Standard Mount Proximity Probe | Standard | 8 mm |

| 21504-000-028-05-02 | 8 mm Reverse Mount Proximity Probe | Reverse | 8 mm |

| 21504-000-008-10-02 | 8 mm Reverse Mount Proximity Probe | Reverse | 8 mm |

| 21504-00-20-05-02 | 8 mm Standard Mount Proximity Probe | Standard | 8 mm |

| 21504-00-60-10-02 | 8 mm Standard Mount Proximity Probe | Standard | 8 mm |

Popular Models

| Model Number | Description | Application |

|---|---|---|

| 3300/16-11-01-00-01-00 | Dual Vibration Monitor | Vibration Monitoring |

| 330180-12-00 | Vibration Monitoring Sensor | General Vibration Monitoring |

| 21508-02-12-10-02 | 8 mm Standard Mount Proximity Probe | Shaft Vibration Monitoring |

| 30001-00-20-18-02 | Armored Vibration Probe | Harsh Environment Applications |

| 21500-00-12-10-02 | 5 mm Proximity Probe | Compact Machinery Monitoring |

| 21502-06 | 7200 Series Proximity Probe | General Industrial Applications |

Excellent PLC

Excellent PLC