| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

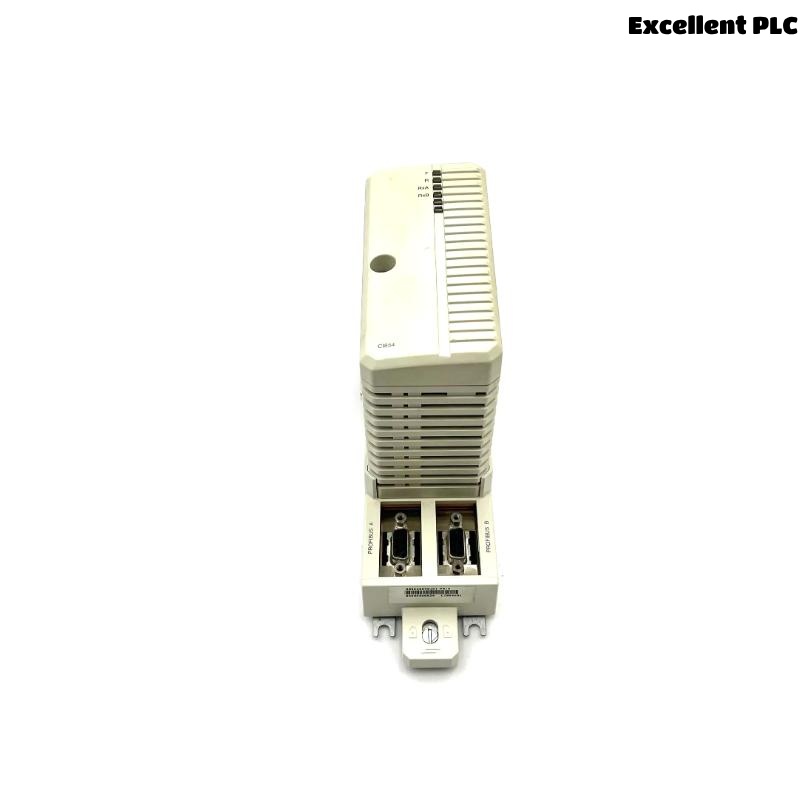

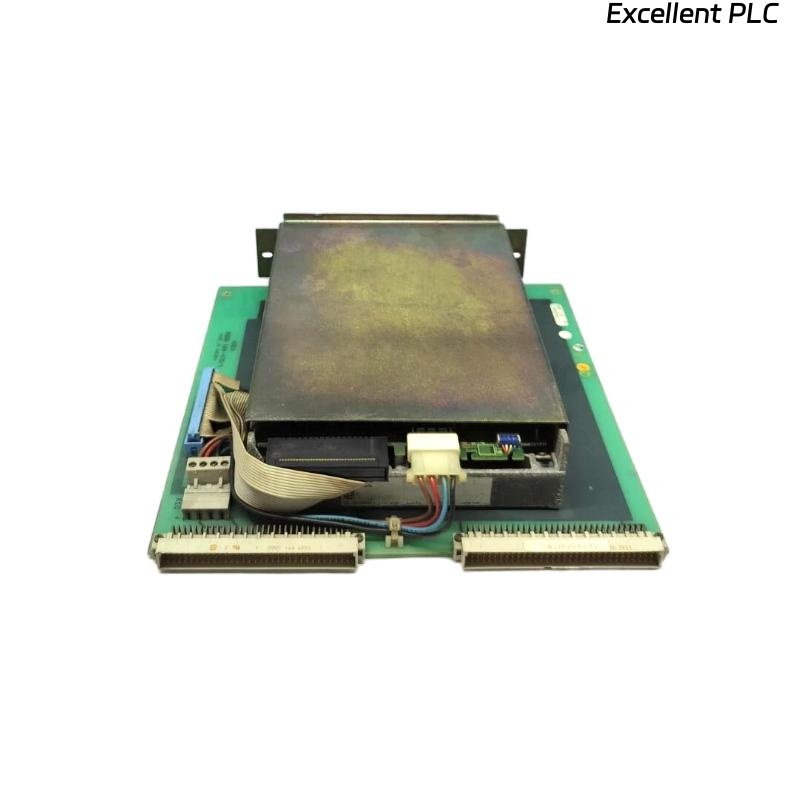

The ABB CI854 3BSE025347R1 is a communication interface module designed for seamless integration between ABB’s AC 800M controllers and FOUNDATION Fieldbus H1 networks. It plays a crucial role in enabling high-performance industrial automation systems to interact with field devices operating on the Fieldbus protocol, ensuring real-time control, reliability, and operational efficiency.

The CI854 module supports two H1 channels and is installed in a communication interface unit (TU854) within the AC 800M system. It complies with the IEC 61158-2 standard for Fieldbus networks, and the module facilitates smooth data exchange, process control, and remote diagnostics.

This module is especially favored in industries such as power generation, oil & gas, chemical processing, and pharmaceuticals, where reliability, safety, and process integrity are paramount.

Product Specifications

| Parameter | Specification |

|---|---|

| Product Model | CI854 |

| Order Code | 3BSE025347R1 |

| Communication Interface | FOUNDATION Fieldbus H1 |

| Number of Channels | 2 independent H1 channels |

| Fieldbus Standard | IEC 61158-2 |

| Redundancy Support | Yes |

| Input Voltage | 24 V DC |

| Power Consumption | Approx. 2 W |

| Operating Temperature | 0 to +55 °C |

| Storage Temperature | -40 to +70 °C |

| Humidity | 5–95% RH (non-condensing) |

| Dimensions (W x H x D) | 150 x 130 x 40 mm |

| Weight | 0.5 kg |

| Mounting | DIN rail (via TU854 base unit) |

| Protection Class | IP20 (when mounted in a cabinet) |

| Supported Controllers | AC 800M (PM861, PM862, PM864, etc.) |

| Firmware Upgradeable | Yes |

| Certifications | CE, RoHS, UL, cUL, ATEX |

Product Applications

The ABB CI854 module is deployed in a wide array of industrial automation environments where robust communication with field devices is required. Key application areas include:

-

Power Plants – Facilitating communication between distributed control systems and smart field instruments.

-

Chemical Processing – Integrating safety and automation systems in highly regulated environments.

-

Oil & Gas – Ensuring real-time data acquisition and control in upstream and downstream processes.

-

Pharmaceutical Manufacturing – Supporting compliance with stringent operational standards and traceability.

-

Water and Wastewater Treatment – Enhancing plant-wide control and diagnostics.

-

Pulp and Paper Industry – Providing reliable process monitoring in harsh operational conditions.

Product Advantages

-

High Integration: Seamlessly connects AC 800M controllers to Fieldbus devices, supporting complex automation scenarios.

-

Dual H1 Channels: Enables connection to two Fieldbus segments, improving scalability and network management.

-

Robust Redundancy: Supports module redundancy, ensuring continuous operation during hardware failure.

-

Real-Time Communication: Designed for deterministic control, essential in mission-critical processes.

-

Scalable Architecture: Can be used in both small-scale and large-scale automation systems.

-

Easy Maintenance: Plug-and-play configuration with hot-swappable modules simplifies system maintenance.

-

Strong Environmental Tolerance: Operates in a wide temperature and humidity range, suited for harsh industrial conditions.

-

Future-Proof: Firmware upgradable to support evolving standards and protocols.

Frequently Asked Questions (FAQ)

1. What does the CI854 module do?

It enables AC 800M controllers to communicate with FOUNDATION Fieldbus H1 devices, providing real-time control and monitoring.

2. Can CI854 be used with redundant controllers?

Yes, it supports full redundancy configurations for fault-tolerant applications.

3. How many Fieldbus channels are supported?

The CI854 provides two independent H1 channels for connecting multiple field devices.

4. Is CI854 compatible with all AC 800M controller types?

Yes, it is compatible with most AC 800M controllers such as PM861, PM862, and PM864.

5. Does the CI854 require a specific terminal unit?

Yes, it is typically installed in the TU854 terminal unit.

6. Can firmware be updated in the field?

Yes, the firmware can be updated via ABB’s Control Builder tools.

7. What is the recommended power supply for CI854?

It operates on a 24 V DC power supply with approximately 2 W power consumption.

8. Is the module suitable for hazardous environments?

Yes, it has ATEX certification and can be used in approved hazardous locations.

9. How is the module mounted?

It is DIN-rail mounted via the TU854 interface unit.

10. Does the CI854 support diagnostics and asset management?

Yes, it supports diagnostics of Fieldbus devices, enhancing predictive maintenance.

Recommended Related Models (Same Series or Communication Purpose)

| Model | Function | Communication Type | Dimensions (mm) | Weight (g) |

|---|---|---|---|---|

| CI854AK01 | Fieldbus communication module kit | FOUNDATION Fieldbus | 59 x 186 x 127 | 260 |

| CI853 | PROFIBUS DP communication interface | PROFIBUS DP | 59 x 186 x 127 | 250 |

| CI851 | MODBUS RTU interface | MODBUS | 59 x 186 x 127 | 240 |

| CI862 | CAN communication module | CANopen | 59 x 186 x 127 | 250 |

| TU854 | Base unit for CI854 module | — | — | 120 |

| PM861 | AC 800M controller unit | — | 115 x 186 x 127 | 500 |

Popular ABB Models (Across Automation & Control)

| Model | Function | Series | Dimensions (mm) | Weight (g) |

|---|---|---|---|---|

| AC800M PM864 | High-performance CPU for control systems | AC 800M | 115 x 186 x 127 | 520 |

| AI810 | Analog input module (8 channels) | S800 I/O | 45 x 120 x 100 | 220 |

| DO810 | Digital output module (16 channels) | S800 I/O | 45 x 120 x 100 | 210 |

| CI840A | Communication interface (CEX bus) | S800 I/O | 45 x 120 x 100 | 230 |

| PM866 | CPU unit for advanced control applications | AC 800M | 115 x 186 x 127 | 540 |

| CP600 HMI | Touch panel operator interface | CP600 Series | Varies (7-15″) | ~1000–3000 |

Excellent PLC

Excellent PLC