| Company Information | ||||||||

| sales@xmjzjsgs.com | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

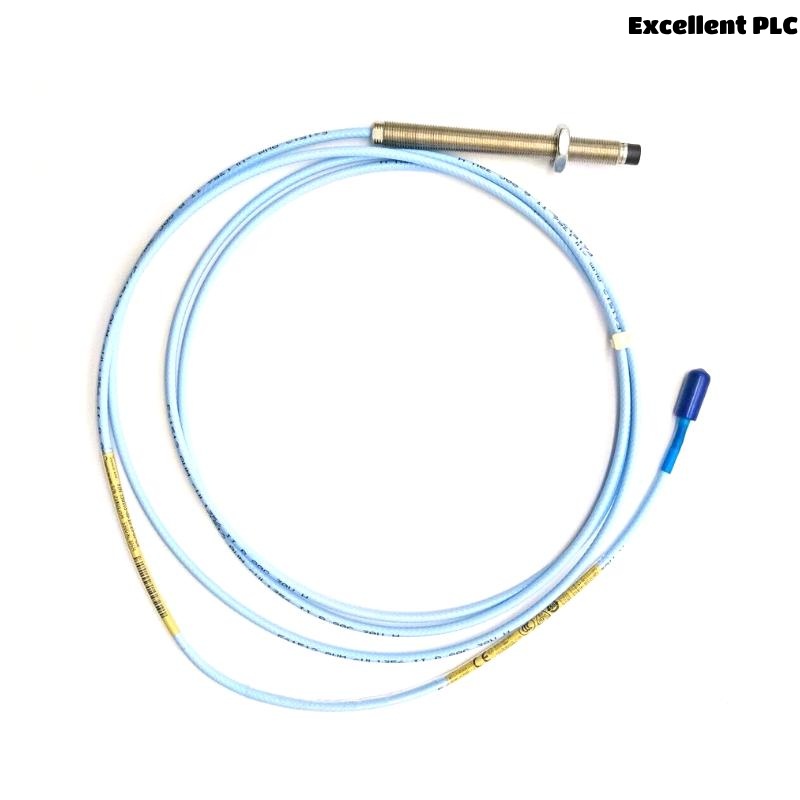

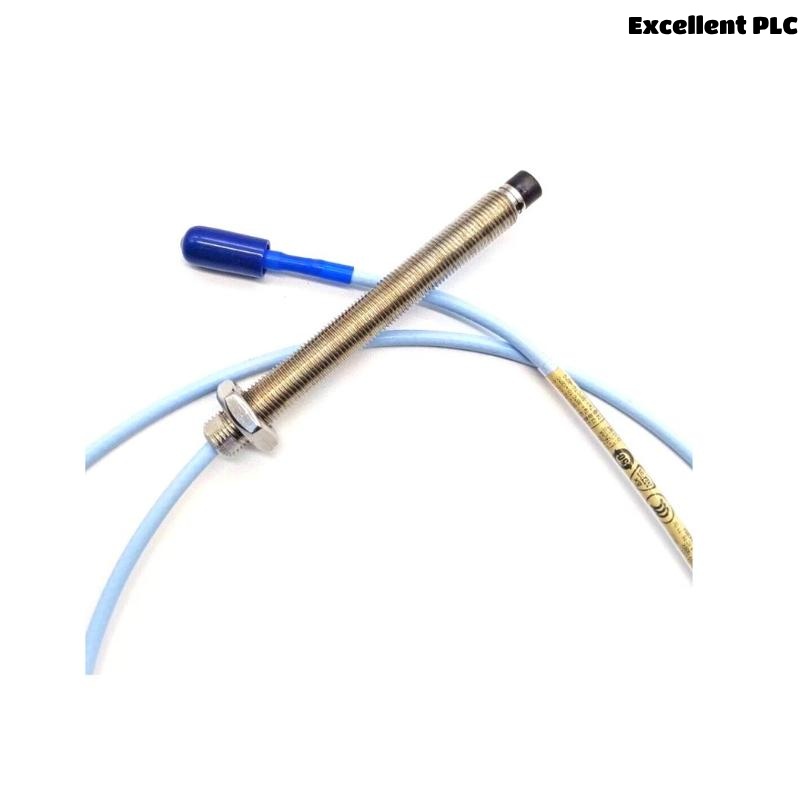

The Bently Nevada 330103-00-12-05-02-00 is an advanced 8 mm proximity probe from the renowned 3300 XL series. Designed for precise monitoring of shaft displacement and vibration, this probe is a crucial component in Bently Nevada’s condition monitoring and predictive maintenance systems. The 3300 XL series is known for its high accuracy, robustness, and versatility in a variety of industrial applications, making it an indispensable tool in industries where machinery reliability and uptime are critical.

The 3300 XL 8 mm proximity probe is typically used in rotating machinery, such as turbines, compressors, and pumps, providing real-time data that helps detect early signs of mechanical issues. With its durable design, exceptional sensitivity, and ease of integration, the 330103-00-12-05-02-00 probe helps minimize the risk of unplanned downtime and extends the life of expensive machinery.

Product Parameters

| Parameter | Value |

|---|---|

| Model Number | 330103-00-12-05-02-00 |

| Probe Type | 3300 XL 8 mm |

| Measurement Type | Proximity |

| Total Length | 0.5 meter |

| Weight | 0.161 kg |

| Diameter | 8 mm |

| Shaft Size | Compatible with shafts up to 150 mm in diameter |

| Output Type | DC Voltage |

| Cable Length | 0.5 meter |

| Operating Temperature | -40°C to +120°C |

| Mounting Type | Integral Mounting |

| Sensitivity | High Sensitivity |

| Protection Class | IP67 |

Applications

The Bently Nevada 330103-00-12-05-02-00 proximity probe is engineered for use in a variety of industries where continuous monitoring of rotating equipment is essential. It finds its primary applications in:

-

Rotating Machinery Vibration Monitoring: Ideal for monitoring vibrations and shaft displacement in critical rotating machinery such as turbines, compressors, and motors.

-

Predictive Maintenance: The probe allows for early detection of mechanical failures by continuously monitoring shaft behavior, which helps in making maintenance decisions based on actual machine condition.

-

Power Generation: In power plants, the probe ensures turbines, pumps, and motors are operating optimally, preventing costly unplanned downtimes and enhancing operational reliability.

-

Manufacturing: Used in manufacturing plants to monitor the performance of industrial machinery such as presses, mixers, and conveyor belts.

-

Condition-Based Monitoring Systems: The probe plays a critical role in automated vibration monitoring systems, allowing for real-time fault detection and extended equipment life.

Product Advantages

-

Precise Vibration Detection: The 3300 XL 8 mm proximity probe offers highly accurate displacement measurements, enabling early detection of faults before they escalate into major issues.

-

Durability in Harsh Environments: With its robust construction, the probe is designed to withstand extreme industrial conditions, including high temperatures and vibrations, ensuring long-lasting performance.

-

Integration with Bently Nevada Systems: The probe is fully compatible with other Bently Nevada monitoring systems, allowing for easy integration into existing condition monitoring setups.

-

Enhanced Sensitivity: This probe has a high sensitivity to minute vibration changes, ensuring that even small irregularities are detected before they cause failure.

-

Long-Term Reliability: The 3300 XL series probes are known for their long service life, which reduces the need for frequent replacements and maintenance, making them a cost-effective solution.

-

Minimal Installation Time: The integral mounting design allows for quick and easy installation, minimizing downtime during setup.

-

Wide Temperature Range: The probe operates effectively in a broad temperature range, from -40°C to +120°C, ensuring reliability in both cold and hot environments.

Frequently Asked Questions (FAQs)

-

What is the operating temperature range of the 3300 XL 8 mm proximity probe?

-

The 3300 XL 8 mm proximity probe operates within an extensive temperature range of -40°C to +120°C, ensuring reliable performance in a variety of industrial environments.

-

-

How is the 3300 XL proximity probe installed?

-

The probe features an integral mounting system that simplifies installation, ensuring a secure fit without requiring complex tools or procedures.

-

-

What shaft sizes can the 3300 XL 8 mm proximity probe monitor?

-

This probe is suitable for shafts up to 150 mm in diameter, making it versatile for a wide range of industrial applications.

-

-

Can the 3300 XL 8 mm proximity probe be used in hazardous environments?

-

Yes, the probe is designed to function reliably in harsh and hazardous environments, such as those found in power generation and heavy manufacturing.

-

-

What type of output does the 3300 XL 8 mm proximity probe provide?

-

The probe provides a DC voltage output, which integrates easily with other vibration monitoring equipment for real-time data analysis.

-

-

Is the 3300 XL proximity probe compatible with other Bently Nevada monitoring systems?

-

Yes, this probe is fully compatible with a wide range of Bently Nevada systems, allowing for seamless integration into existing monitoring setups.

-

-

How does the 3300 XL 8 mm proximity probe aid in predictive maintenance?

-

By monitoring vibrations and shaft displacements, the probe helps identify issues early, enabling maintenance activities to be scheduled before equipment failure occurs.

-

-

What industries benefit from using the 3300 XL proximity probe?

-

The 3300 XL 8 mm proximity probe is widely used in industries such as power generation, chemical manufacturing, mining, and heavy machinery, where machinery uptime is crucial.

-

-

What is the sensitivity of the 3300 XL 8 mm proximity probe?

-

The probe has a high sensitivity, allowing it to detect even the smallest changes in machinery behavior, which is crucial for early fault detection.

-

-

How often should the 3300 XL proximity probe be calibrated?

-

Regular calibration is recommended to maintain optimal performance, although the probe’s design ensures it remains stable and accurate with minimal maintenance.

Related Models

| Model | Description |

|---|---|

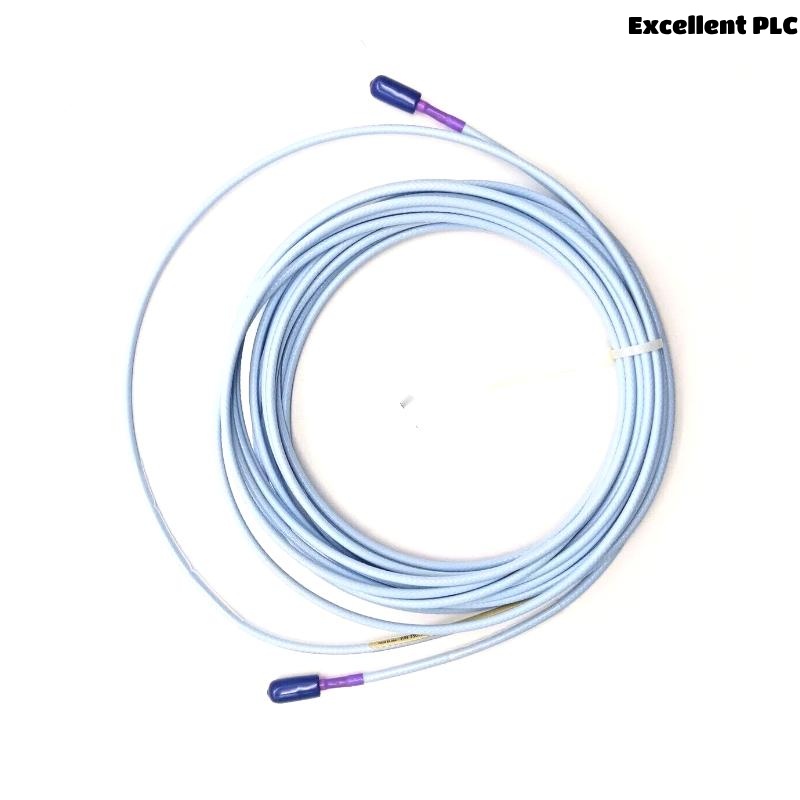

| 330104-00-12-05-02-00 | 3300 XL 8 mm proximity probe with extended cable |

| 330103-00-12-05-02-01 | 3300 XL 8 mm proximity probe (standard configuration) |

| 330101-00-12-05-02-00 | 3300 XL 5 mm proximity probe |

| 330106-00-12-05-02-00 | 3300 XL 12 mm proximity probe |

| 330102-00-12-05-02-00 | 3300 XL 8 mm proximity probe with higher sensitivity |

| 330107-00-12-05-02-00 | 3300 XL 8 mm proximity probe with enhanced durability |

Popular Bently Nevada Models

| Model | Description |

|---|---|

| 330500-00-01-10-00-00 | 3300 XL 8 mm vibration probe |

| 330350-00-01-00-00-00 | 3300 XL vibration monitoring system |

| 330420-00-01-01-01-00 | 3300 XL vibration transducer |

| 330400-00-02-10-02-00 | 3300 XL 10 mm proximity probe |

| 330101-00-01-10-00-00 | 3300 XL system with 5 mm probe |

| 350101-00-02-10-00-01 | 3500 vibration monitoring system |

Excellent PLC

Excellent PLC