| Company Information | ||||||||

| sales@xmjzjsgs.com | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

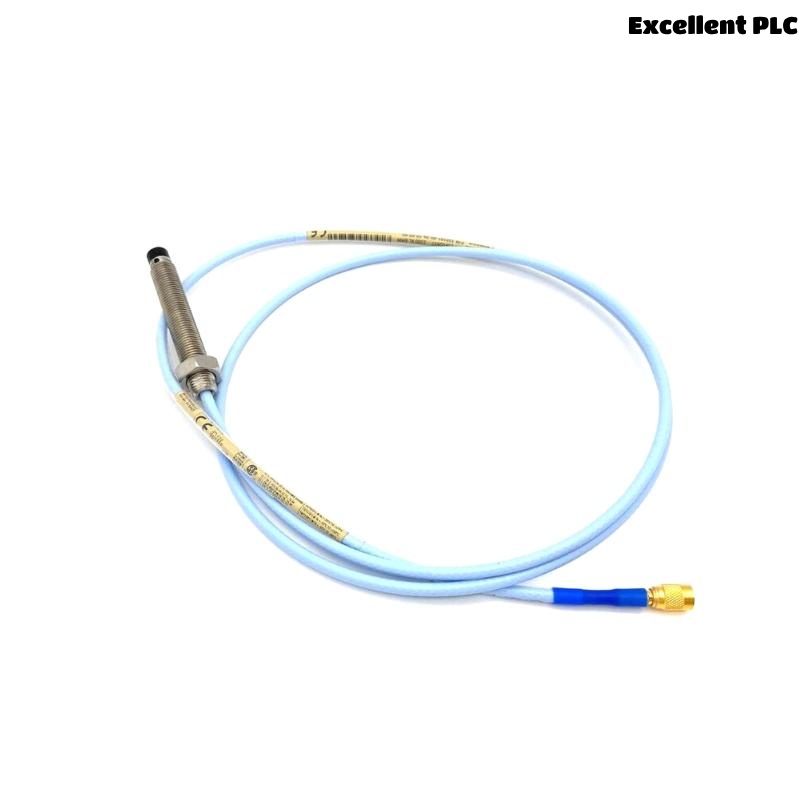

The Bently Nevada 21000-16-10-00-144-03-02 is a robust and precisely engineered proximity probe housing assembly designed to protect and securely position proximity probes in industrial machinery monitoring systems. As part of Bently Nevada’s renowned line of vibration and shaft displacement monitoring components, this housing ensures the probe’s accuracy and durability even under challenging operational environments.

Used primarily in large rotating equipment like turbines, compressors, and motors, the housing assembly provides a stable mounting platform that isolates the probe from mechanical vibrations and environmental contaminants. Its corrosion-resistant construction and precise engineering help deliver consistent, reliable data essential for predictive maintenance and avoiding unplanned downtime.

Product Specifications

| Parameter | Description |

|---|---|

| Model Number | 21000-16-10-00-144-03-02 |

| Product Type | Proximity Probe Housing Assembly |

| Material | Stainless Steel |

| Supported Probe Diameter | Typically 8 mm (compatible with standard probes) |

| Mounting Style | Threaded or flange mount (application dependent) |

| Housing Body Diameter | 83.3 mm |

| Weight | 1.1 kg |

| Operating Temperature Range | -40°C to +125°C |

| Environmental Protection | Resistant to dust, moisture, and vibration |

| Compatible Probes | Bently Nevada standard proximity probes |

| Certifications | Industrial-grade compliance |

Applications

The housing assembly is essential for safeguarding proximity probes in various industries, including:

-

Power Generation: Ensures accurate vibration and shaft displacement monitoring in turbines and generators.

-

Oil & Gas: Used in pumps and compressors operating in harsh environments to secure probe positioning.

-

Manufacturing: Applied in critical rotating machinery for early detection of faults.

-

Marine: Suitable for shipboard machinery monitoring due to corrosion resistance.

-

Aerospace: Used in specialized equipment for monitoring rotating parts.

-

Industrial Plants: Employed across various sectors where rotating equipment health monitoring is critical.

Advantages

-

Durability: Made of corrosion-resistant stainless steel, built to withstand harsh environmental conditions.

-

Precision Engineering: Ensures stable and accurate placement of proximity probes, improving measurement reliability.

-

Wide Temperature Tolerance: Functions effectively from -40°C up to +125°C, supporting diverse industrial environments.

-

Versatile Mounting Options: Threaded and flange mounts available, facilitating easy installation on different machinery.

-

Environmental Protection: Protects probes from moisture, dust, and mechanical shock.

-

Lightweight: At just 1.1 kg, it adds minimal load to machinery without compromising durability.

-

Ease of Maintenance: Designed for long-term use with minimal maintenance needs.

-

Compatibility: Works seamlessly with Bently Nevada’s proximity probes, ensuring integrated system performance.

-

Proven Reliability: Trusted by industry professionals worldwide for critical machine monitoring.

Frequently Asked Questions (FAQ)

-

What is the purpose of this proximity probe housing?

It protects and securely holds the proximity probe in place, ensuring accurate readings of shaft displacement and vibration. -

What material is used for this housing assembly?

The housing is made of stainless steel for strength and corrosion resistance. -

Is this housing suitable for harsh environments?

Yes, it is designed to resist dust, moisture, and mechanical vibration. -

What is the supported temperature range?

It operates reliably between -40°C and +125°C. -

Can this housing fit all types of proximity probes?

It is compatible with standard Bently Nevada proximity probes, typically 8 mm in diameter. -

How is the housing mounted?

It supports threaded or flange mounting, depending on the machinery and application. -

Does the housing affect the accuracy of probe measurements?

When properly installed, it maintains probe stability, ensuring precise measurements. -

What maintenance does the housing require?

Generally, it requires only routine inspection for wear or corrosion. -

Is this housing assembly suitable for offshore or marine use?

Yes, its corrosion resistance makes it suitable for marine environments. -

How do I verify compatibility with my equipment?

Check the probe diameter and mounting specifications or consult Bently Nevada technical support.

Recommended Related Models (Same Series or Related)

| Model Number | Description | Length (mm) | Diameter (mm) | Weight (kg) | Notes |

|---|---|---|---|---|---|

| 21000-16-10-00-124-03-02 | Proximity Probe Housing Assembly | 100 | 25 | 0.15 | Earlier model, slightly smaller |

| 21000-16-10-00-144-04-02 | Probe Housing with Flange Mount | 115 | 28 | 0.18 | Flange mount design |

| 21000-16-10-00-144-05-02 | High Temp Housing Assembly | 110 | 27 | 0.17 | Enhanced temperature resistance |

| 21000-16-10-00-144-06-02 | Compact Probe Housing Assembly | 90 | 23 | 0.13 | Designed for tight spaces |

| 21000-16-10-00-144-07-02 | Probe Housing with Integrated Seal | 110 | 28 | 0.18 | Improved environmental seal |

| 21000-16-10-00-144-08-02 | Heavy Duty Probe Housing Assembly | 120 | 30 | 0.20 | Suitable for heavy industrial use |

Popular Bently Nevada Models (Same Brand)

| Model Number | Description | Type | Key Feature | Weight (kg) | Notes |

|---|---|---|---|---|---|

| 330105-00-02 | 3500 Series Proximity Probe | Proximity Probe | High accuracy, rugged design | 0.1 | Widely used in turbine monitoring |

| 330103-00-02 | 3500 Series Vibration Sensor | Vibration Sensor | Piezoelectric sensor | 0.12 | Reliable vibration monitoring |

| 134-680-00 | 3500/50 Vibration Monitor Module | Monitor Module | Real-time vibration analysis | 0.25 | Integrated monitoring system |

| 134-126-00 | 3500/46 Vibration Monitor Module | Monitor Module | High sensitivity monitoring | 0.22 | Popular in power generation |

| 330120-00 | 3500 Series Speed Sensor | Speed Sensor | Precise shaft speed measurement | 0.08 | Essential for rotating machinery |

| 330110-00 | 3500/22 Proximitor Sensor | Proximitor Sensor | Shaft displacement detection | 0.11 | Core component in monitoring systems |

Excellent PLC

Excellent PLC