| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

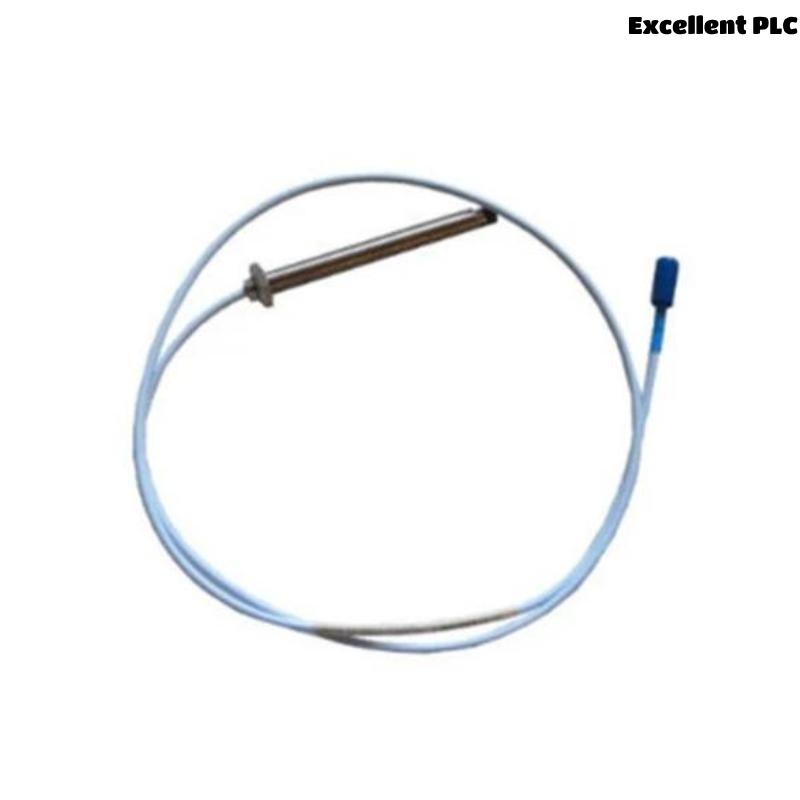

The Bently Nevada 330104-00-07-10-01-05 is an advanced 8 mm proximity probe designed for the precise monitoring of rotating machinery, offering exceptional reliability and high-performance measurement. Part of the 3300 XL series, this proximity probe utilizes eddy current technology to provide accurate and consistent measurement of vibration and displacement.

With a total length of 1.0 meter and a weight of just 0.323 kg, the probe is equipped with a rugged stainless steel tip and metric connectors, ensuring durability and ease of installation in industrial environments. It is ideal for a variety of applications in machinery condition monitoring, helping to detect potential issues before they lead to failures, ultimately preventing downtime and reducing maintenance costs.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | 330104-00-07-10-01-05 |

| Probe Tip Diameter | 8 mm |

| Total Length | 1.0 meter |

| Weight | 0.323 kg |

| Sensing Technology | Eddy Current |

| Measurement Range | Up to 1.27 mm (50 mils) typical |

| Operating Temperature | -40°C to +120°C |

| Mounting Type | Threaded Mount |

| Connector Type | Metric |

| Probe Material | Stainless Steel |

| Vibration Resistance | High |

| Shielding | Yes |

Product Applications

The Bently Nevada 330104-00-07-10-01-05 proximity probe is widely utilized in various industrial sectors to monitor the health of rotating machinery. Its precision and reliability make it suitable for:

-

Turbines (both gas and steam) to monitor vibration and shaft displacement

-

Compressors in gas and oil applications for early detection of shaft misalignment or vibration problems

-

Pumps used in chemical plants, refineries, and water treatment facilities to detect abnormal movement

-

Motors and generators in power plants for ensuring smooth operation and minimizing risk

-

Gearboxes and drives in heavy industrial machinery to avoid mechanical failures

-

Marine systems including offshore platforms and marine propulsion systems that require high durability

This proximity probe is especially beneficial in systems where maintenance is critical and downtime is costly. It aids in predictive maintenance and helps avoid unplanned shutdowns.

Product Advantages

-

Non-contact measurement ensures wear-free operation, extending the life of the probe and the machinery.

-

Metric connector simplifies installation in international or metric-standard plants.

-

Rugged stainless steel probe tip is resistant to wear and damage in harsh industrial environments.

-

Shielded cable minimizes electrical interference and improves signal integrity, ensuring accurate measurements.

-

Wide operating temperature range allows the probe to function in both high- and low-temperature environments.

-

Threaded mounting allows for easy and secure installation, providing flexibility during setup.

-

Lightweight (0.323 kg) reduces the mechanical load on machines, preventing additional strain.

-

Proven reliability in critical machinery monitoring, making it a trusted choice for industrial applications.

-

Prevents costly machine failures by continuously monitoring displacement and vibration.

-

Supports predictive maintenance strategies, reducing unexpected downtimes and extending equipment lifespan.

Frequently Asked Questions (FAQ)

-

What machines can the Bently Nevada 330104-00-07-10-01-05 probe be used with?

It is suitable for use with turbines, compressors, pumps, motors, gearboxes, and other rotating machinery. -

What is the maximum displacement measurement range of this probe?

The probe can measure up to 1.27 mm (50 mils) of shaft displacement. -

What is the probe’s total length?

The probe’s total length is 1.0 meter. -

What is the weight of the Bently Nevada 330104-00-07-10-01-05 probe?

The total weight of the probe is 0.323 kg. -

Can the Bently Nevada 330104-00-07-10-01-05 probe operate in extreme temperatures?

Yes, it operates within a wide temperature range from -40°C to +120°C. -

Does the probe come with a metric connector?

Yes, the probe is equipped with a metric connector for compatibility with metric systems. -

What type of mounting does the Bently Nevada 330104-00-07-10-01-05 probe use?

The probe uses a threaded mounting method for easy and secure installation. -

Can this probe be used for marine or offshore applications?

Yes, its durable design makes it ideal for marine environments and offshore platforms. -

How does this probe measure vibration?

The probe uses eddy current sensing technology to measure displacement and vibration in rotating machinery. -

How frequently should this probe be inspected or replaced?

While the probe is designed for long service life, it should be regularly checked during maintenance intervals to ensure optimal performance.

Recommended Related Models

| Model Number | Description |

|---|---|

| 330104-00-07-10-02-00 | 8 mm Proximity Probe (metric, standard connector) |

| 330110-00-07-10-02-00 | High Temperature 8 mm Proximity Probe |

| 330106-00-07-10-02-00 | 5 mm Proximity Probe (metric) |

| 330180-91-05 | Reverse Mount Proximity Probe |

| 330130-00-07-10-02-00 | Ruggedized 8 mm Proximity Probe |

| 330105-00-07-10-02-00 | 8 mm Proximity Probe for harsh environments |

Popular Bently Nevada Models

| Model Number | Description |

|---|---|

| 3500/05-03-02-00 | System Rack for 3500 Monitoring Systems |

| 3500/22-01-01-00 | Transient Data Interface Module |

| 3500/40M-01-00 | Proximitor Monitor |

| 3500/42M-01-00 | Vibration Monitor |

| 330103-00-05-10-02-00 | High Temperature 8 mm Proximity Probe |

| 330106-05-30-10-02-00 | 5 mm Proximity Probe, Panel Mount |

Excellent PLC

Excellent PLC