| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Overview

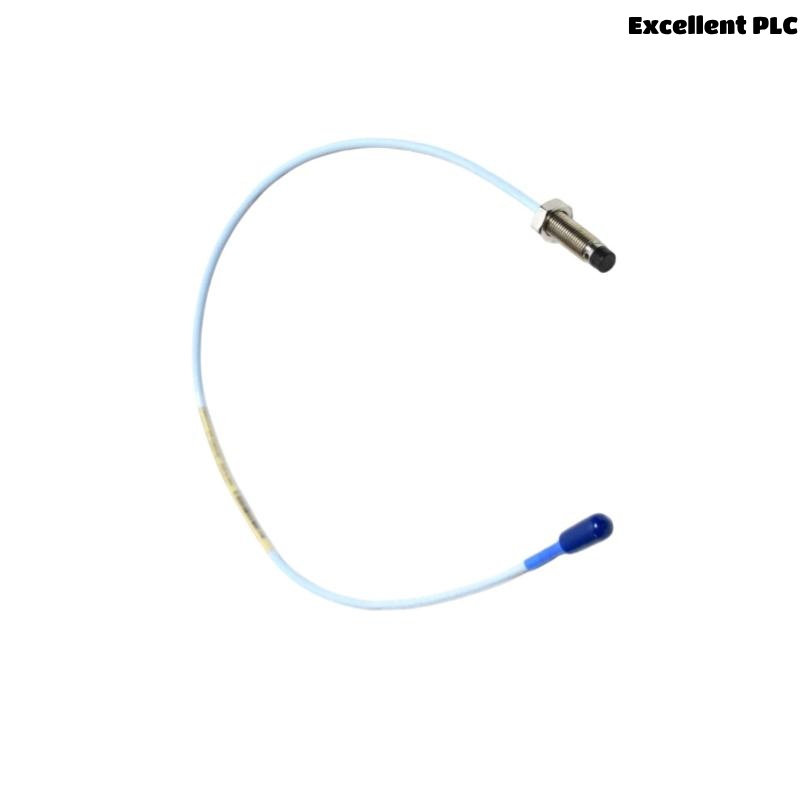

The Bently Nevada 330101-00-14-10-02-05 is part of the 3300 XL 8 mm Proximity Transducer System, which includes a probe, extension cable, and proximitor sensor. This system is widely used in critical rotating machinery monitoring to detect and measure shaft vibration, axial thrust, and position displacement.

As a component of the 3300 XL series, this probe features a rugged design, enhanced EMI immunity, and highly stable performance across a wide range of temperatures and environmental conditions. It is specifically tuned for API 670-compliant applications and optimized for standard Bently Nevada proximitor interfaces.

Key Features

-

8 mm tip diameter for high-precision shaft position sensing

-

Compatible with 3300 XL Extension Cable and Proximitor Sensor

-

Designed per API 670 industry standards

-

Pre-configured system length: 14 ft (4.3 m) total system

-

Enhanced EMI/RFI shielding for noise immunity in harsh environments

-

Standard 10 ft extension cable and 4 ft probe included

-

Polyurethane cable jacket for chemical resistance and flexibility

-

Durable probe tip for direct mounting in high-vibration zones

-

Compatible with a wide range of Bently Nevada monitoring systems

Technical Specifications

| Parameter | Specification |

|---|---|

| Probe Tip Diameter | 8 mm |

| Probe Length | 4 ft (1.2 m) |

| Extension Cable Length | 10 ft (3.0 m) |

| Total System Length | 14 ft (4.3 m) |

| Thread Size | 3/8-24 UNF (standard mounting) |

| Connector Type | Miniature coaxial connector |

| Linear Range | 2 mm (80 mils) |

| Sensitivity | 7.87 mV/μm (200 mV/mil) |

| Non-linearity | ±0.25% of full scale |

| Operating Temperature | -35°C to +177°C (Probe and Cable) |

| Frequency Response | DC to 10 kHz |

| Material | Probe body: AISI 303 Stainless Steel; Tip: PEEK |

| Insulation Resistance | >10 GΩ |

| Environmental Protection | IP67 |

| Compliance | RoHS, CE, ATEX/IECEx (select variants) |

| Dimensions | Total Length : 1.0 meters |

| Weight | 0.323 kg |

Product Advantages

-

Industry-Proven Reliability: Extensively deployed in industrial turbines, motors, compressors, and pumps.

-

High Accuracy: Excellent linearity across the measurement range ensures precise vibration analysis.

-

Mechanical Ruggedness: Suitable for mounting near high-temperature, high-vibration areas.

-

Electromagnetic Immunity: Designed for stable operation near VFDs, SCRs, and other noisy equipment.

-

Flexible Configurations: Wide range of extension cable and proximitor options.

-

Field Compatibility: Compatible with legacy and modern Bently Nevada monitoring systems.

-

Oil & Gas Ready: Certified and widely used in hazardous area installations.

Industry Applications

-

Steam and Gas Turbines (Axial Thrust Monitoring)

-

Compressors (Radial Vibration Monitoring)

-

Electric Motors (Shaft Position Detection)

-

Pumps (Dynamic Performance Evaluation)

-

Refineries and Petrochemical Plants

-

Power Generation (Thermal, Hydro, Nuclear)

-

Mining and Pulp & Paper Equipment Monitoring

The 330101-00-14-10-02-05 proximity probe is a critical component in predictive maintenance and rotating machinery protection systems, enabling real-time condition monitoring and early fault detection.

Frequently Asked Questions (FAQ)

-

Q: What does the part number 330101-00-14-10-02-05 represent?

A: It encodes the system configuration—specifically a 14 ft total length system with a 10 ft extension cable and 4 ft probe. -

Q: Can this probe be used with non-Bently proximitor sensors?

A: It is designed for Bently Nevada proximitor sensors and may not function accurately with other brands. -

Q: What is the standard output sensitivity?

A: 200 mV/mil (7.87 mV/μm), in compliance with API 670. -

Q: Is the probe safe for hazardous area installation?

A: Yes, certain variants are certified ATEX/IECEx for hazardous environments. -

Q: How is the probe mounted?

A: Typically threaded into a mounting bracket or probe holder using the 3/8-24 UNF thread. -

Q: Can I shorten the cable if needed?

A: No, altering cable length affects calibration. Use factory-set lengths. -

Q: Does it support high-speed machinery monitoring?

A: Yes, up to 10 kHz frequency response for high-speed shaft vibration. -

Q: What materials are used in the probe tip?

A: A rugged PEEK (polyether ether ketone) non-conductive material. -

Q: Can this probe be submerged in oil?

A: Yes, the IP67 rating allows operation in oil-lubricated environments. -

Q: Is the probe interchangeable with other 3300 XL models?

A: Yes, provided the total system length and components are matched accordingly.

Related or Compatible Models (Same Series)

| Model | Description |

|---|---|

| 330101-00-10-10-02-00 | 10 ft system with 10 ft extension and 0 ft probe |

| 330101-00-20-10-02-00 | 20 ft system; 10 ft cable and 10 ft probe |

| 330104-00-05-10-02-00 | 8 mm XL probe, alternative configuration |

| 330130-040-00-00 | 3300 XL Extension Cable – 40 ft |

| 330180-91-05 | 3300 XL Proximitor Sensor for 8 mm probes |

| 330105-02-12-10-02-00 | High-temperature variant of 8 mm XL probe |

Popular Bently Nevada Models (Same Brand)

| Model | Description |

|---|---|

| 3500/42M | Vibration Monitor Module for 3500 series |

| 330180-90-00 | 3300 XL Proximitor Sensor, standard configuration |

| 330104-00-03-05-02-00 | 8 mm Proximity Probe, 3 ft probe and 5 ft cable |

| 3500/15-05-05-00 | AC Power Supply Module for 3500 rack system |

| 330130-080-00-00 | XL Extension Cable, 80 ft variant |

| 3500/22M | Transient Data Interface Module for external communication |

Excellent PLC

Excellent PLC