| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

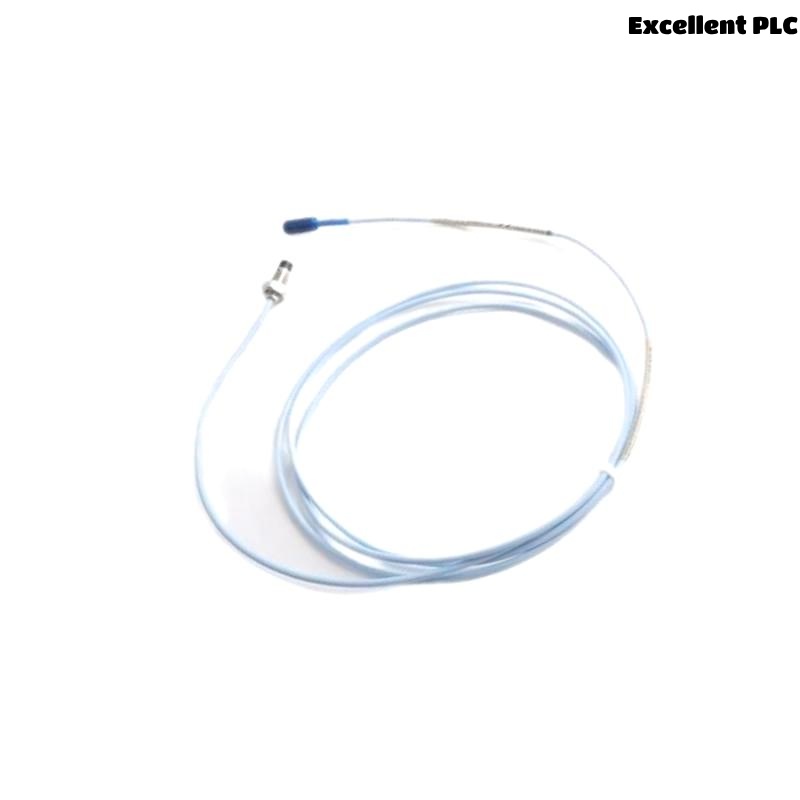

Bently Nevada 330101-00-08-20-02-CN Product Overview

The Bently Nevada 330101-00-08-20-02-CN is a high-performance vibration monitoring sensor designed for industrial applications. It is part of the Bently Nevada 3300 series, renowned for its reliability and precision in machinery protection and condition monitoring. This sensor is widely used in critical rotating equipment across industries such as oil & gas, power generation, and manufacturing.

Product Parameters

The technical specifications of the Bently Nevada 330101-00-08-20-02-CN are as follows:

| Parameter | Specification |

|---|---|

| Model Number | 330101-00-08-20-02-CN |

| Type | Proximity Vibration Sensor |

| Measurement Range | 0 to 20 mm (peak-to-peak) |

| Output Signal | 4–20 mA (linear to vibration) |

| Frequency Response | 0.5 to 1000 Hz |

| Operating Voltage | 18–30 VDC |

| Temperature Range | -40°C to +85°C (-40°F to +185°F) |

| Housing Material | Stainless Steel |

| Connector Type | Integral Cable or DIN Connector |

| Cable length | 2 m |

| Weight | 0.646 kg |

| Certifications | ATEX, IECEx, CE, SIL 2 Compliant |

Product Applications

The Bently Nevada 330101-00-08-20-02-CN is ideal for:

-

Rotating Machinery Monitoring: Turbines, compressors, pumps, and motors.

-

Industrial Equipment Protection: Detects misalignment, imbalance, and bearing wear.

-

Power Plants: Ensures safe operation of generators and turbines.

-

Oil & Gas: Monitors critical equipment in refineries and pipelines.

-

Manufacturing: Prevents downtime in production lines.

Product Advantages

-

High Accuracy: Provides precise vibration measurements for early fault detection.

-

Robust Construction: Stainless steel housing ensures durability in harsh environments.

-

Wide Compatibility: Integrates seamlessly with Bently Nevada monitoring systems.

-

Certified Safety: Complies with ATEX and IECEx for hazardous areas.

-

Low Maintenance: Designed for long-term reliability with minimal upkeep.

Frequently Asked Questions (FAQ)

-

What is the operating voltage range of this sensor?

The sensor operates at 18–30 VDC. -

Can this sensor be used in explosive environments?

Yes, it is ATEX and IECEx certified for hazardous areas. -

What is the frequency response range?

0.5 to 1000 Hz. -

How is the sensor mounted?

It can be mounted via threaded stud or flange, depending on the application. -

Is the output signal linear?

Yes, the 4–20 mA output is linear to vibration levels. -

What is the temperature limit for operation?

-40°C to +85°C (-40°F to +185°F). -

Does it require regular calibration?

Periodic calibration is recommended for optimal performance. -

Can it measure shaft displacement?

Yes, it is designed for proximity-based displacement measurement. -

What is the warranty period?

Typically 12–24 months, depending on the supplier. -

Is it compatible with third-party monitoring systems?

Yes, but optimal performance is achieved with Bently Nevada systems.

Recommended Related & Popular Models

Same Series (3300 Series)

| Model Number | Description |

|---|---|

| 330101-00-05-10-02-CN | 5 mm range vibration sensor |

| 330104-00-10-20-02-CN | 10 mm range, high-temperature variant |

| 330105-00-20-50-02-CN | 20 mm range, heavy-duty application |

| 330850-90-00 | Proximitor® Seismic Sensor |

| 330180-90-00 | Velocity Sensor |

| 330701-00-00-00-00 | Accelerometer for high-frequency vibration |

Popular Bently Nevada Models

| Model Number | Description |

|---|---|

| 3500/42M | Vibration Monitoring Module |

| 3500/22M | Proximitor® Seismic Monitor |

| 1900/65A | Accelerometer for industrial use |

| 3300 XL 8mm | Extended Range Proximity Sensor |

| 3701/20-01-00-00 | Transient Data Interface Module |

| 3500/92 | Communication Gateway |

Excellent PLC

Excellent PLC