| Company Information | ||||||||

| sales@xmjzjsgs.com | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

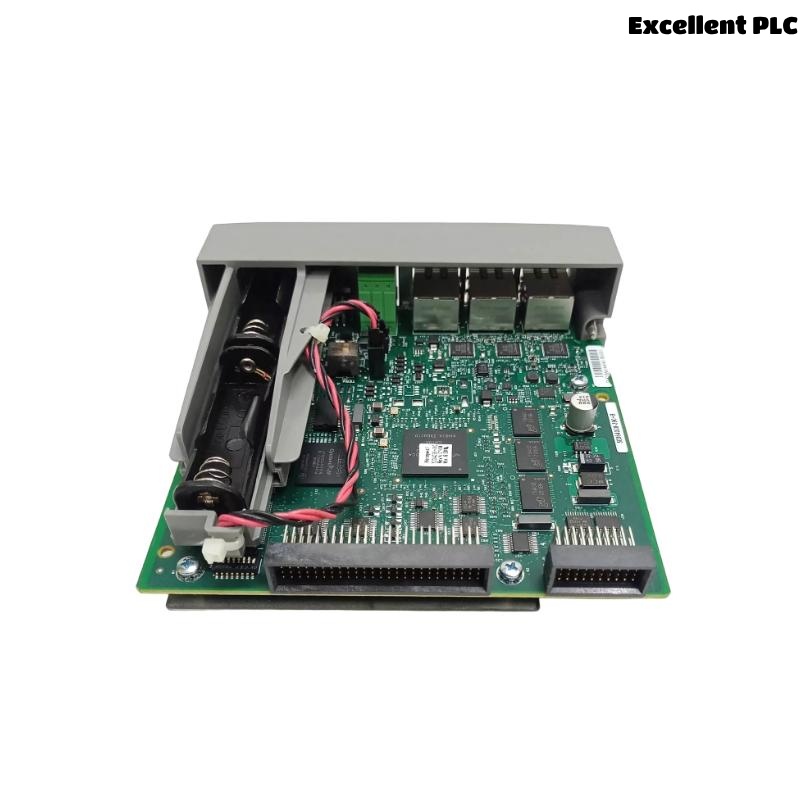

The Honeywell 900C75S-0360-00 HC900 C75 Redundant Controller CPU is an advanced, industrial-grade control unit that is part of the renowned HC900 Hybrid Controller family. This model is designed specifically for applications requiring high availability and fault tolerance, thanks to its redundant CPU architecture. It ensures seamless operation and minimal downtime in demanding industrial environments.

The 900C75S-0360-00 combines robust control performance with flexible communication options, making it a reliable choice for industries such as chemical processing, power generation, water treatment, and pharmaceuticals. With extensive I/O capacity and support for multiple industrial protocols, this controller integrates easily within complex automation systems.

Technical Specifications

| Parameter | Details |

|---|---|

| Model Number | 900C75S-0360-00 |

| Product Type | HC900 C75 Redundant Controller CPU |

| Controller Family | HC900 Hybrid Controller |

| CPU Scan Time | Approximately 25 ms |

| User Memory | 10 MB |

| Maximum I/O Points | Supports up to 4,000 I/O points with expansion |

| Communication Ports | 2 x Ethernet (10/100 Mbps), 1 x RS-485 Serial |

| Supported Protocols | Modbus RTU, Modbus TCP/IP, EtherNet/IP, OPC, Peer-to-Peer |

| Power Supply | 24 VDC |

| Redundancy Support | CPU and communication redundancy |

| Operating Temperature | 0 to 60 °C |

| Storage Temperature | -40 to 85 °C |

| Mounting | DIN Rail |

| Certifications | CE, UL, CSA, RoHS compliant |

| Dimensions (W x H x D) | 137 × 38.1 × 137.16 mm |

| Weight | 0.254 kg |

Product Applications

This redundant controller CPU is widely used in industries requiring continuous operation and high process safety:

-

Chemical and Petrochemical Processing: Ensuring smooth, fault-tolerant batch and continuous process control.

-

Oil & Gas: Redundant control for critical refining and pipeline automation.

-

Pharmaceutical Manufacturing: Maintaining consistent batch quality and regulatory compliance.

-

Water and Wastewater Treatment: Automation of treatment plants with high uptime demands.

-

Power Generation: Reliable control of boilers, turbines, and auxiliary systems.

-

Food and Beverage Industry: Precise recipe and temperature control with minimal interruptions.

The CPU redundancy ensures that in case of any hardware failure, control switches instantly to the backup CPU, preserving process integrity.

Product Advantages

-

Redundant CPU Architecture: Minimizes risk of system downtime by providing instantaneous failover.

-

High Scalability: Supports large numbers of I/O points suitable for complex processes.

-

Multiple Communication Protocols: Facilitates integration with various industrial networks and SCADA systems.

-

Robust Industrial Design: Designed to operate reliably under harsh environmental conditions.

-

Secure Access: Password protection and user access levels safeguard critical control functions.

-

User-Friendly Software: Compatible with Honeywell’s Hybrid Control Designer (HCD) for easy configuration.

-

Comprehensive Diagnostics: Built-in health monitoring and fault alerts reduce troubleshooting time.

-

Modular Design: Simplifies system maintenance and expansion.

-

International Certifications: Complies with major industry standards worldwide.

-

Efficient Process Control: Supports fast scan times and complex logic for dynamic process environments.

Frequently Asked Questions (FAQ)

-

Q: Can the 900C75S-0360-00 operate as a standalone controller?

A: Yes, it can be used both as a standalone or in a redundant CPU pair configuration. -

Q: What software is required for programming and configuration?

A: The Hybrid Control Designer (HCD) software is used for programming, configuration, and diagnostics. -

Q: How many I/O points can this controller handle?

A: It supports up to 4,000 I/O points with the use of expansion modules. -

Q: What communication protocols does this CPU support?

A: It supports Modbus RTU, Modbus TCP/IP, EtherNet/IP, OPC, and peer-to-peer protocols. -

Q: What is the typical scan time for the CPU?

A: The typical CPU scan time is around 25 milliseconds. -

Q: Is remote monitoring and control possible?

A: Yes, through Ethernet and supported communication protocols, remote monitoring is available. -

Q: What redundancy features does this model provide?

A: It provides full CPU redundancy and communication path redundancy. -

Q: What power supply is recommended?

A: A stable 24 VDC power supply, typically from the HC900 base unit, is required. -

Q: How does the controller ensure security?

A: User passwords and access control help secure configuration and operation. -

Q: Can the firmware be updated in the field?

A: Yes, firmware updates are supported via the HCD software and can be applied during scheduled maintenance.

Related Honeywell HC900 Series Models

| Model Number | Description | Key Features |

|---|---|---|

| 900C75-0460 | HC900 C75 Redundant CPU | Similar CPU with standard configuration |

| 900C75-0560 | HC900 C75 Redundant CPU | High-availability CPU with advanced features |

| 900C73R-0100 | HC900 C70 Redundant CPU | Redundant CPU with medium performance |

| 900C50-0101 | HC900 C50 Standard CPU | Entry-level CPU for smaller control systems |

| 900P01-0101 | HC900 Power Module | Power supply module for HC900 |

| 900B01-0101 | HC900 Base Unit | Mounting base for CPU and I/O modules |

Popular Honeywell Industrial Automation Models

| Model Number | Description | Primary Application |

|---|---|---|

| Experion C300 | Advanced Process Controller for DCS | Large-scale distributed process control |

| UDC3500 | Universal Digital Controller | Panel mount PID controller |

| RM7840G1018 | Burner Management Controller | Safety and flame control for burners |

| HC900 I/O Modules | Analog and Digital I/O Expansion Modules | Scalable I/O for HC900 controllers |

| ML200 | Limit Controller | High-limit safety control |

| HC900-C70R | HC900 C70 Redundant CPU | Redundant CPU with moderate processing power |

Excellent PLC

Excellent PLC