| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

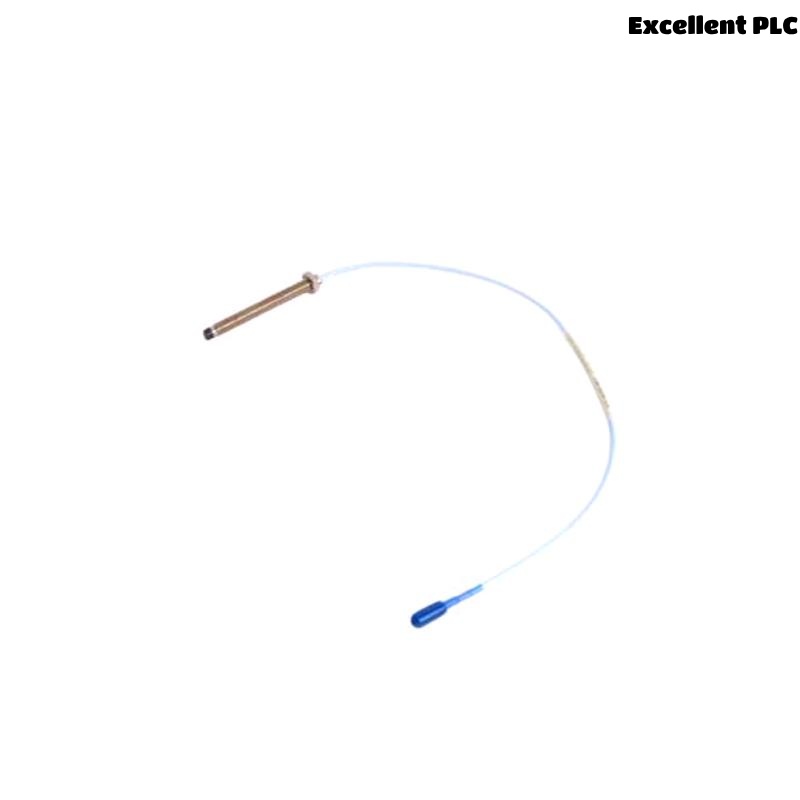

The Bently Nevada 330101-00-20-10-11-05 is part of the 3300 XL 8 mm Proximity Probe series, a highly trusted and widely implemented solution for precision shaft vibration and position monitoring in critical rotating machinery. This specific model features a robust 8 mm probe tip, a 20-inch unarmored cable section, a total system cable length of 10 feet, and a rugged 3/8-24 UNF connector with connector protection.

The 3300 XL series is an advancement of Bently Nevada’s legacy proximity sensing systems, offering improved reliability, temperature performance, and environmental resistance. The probe is typically used in combination with the 3300 XL extension cable and the matching Proximitor Sensor, together forming a complete proximity transducer system.

This model is engineered to operate reliably in harsh industrial environments such as oil & gas plants, power stations, and chemical processing facilities, where accurate vibration and position feedback is crucial to avoid machinery failure or costly downtime.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | 330101-00-20-10-11-05 |

| Series | 3300 XL 8 mm Proximity Probe |

| Tip Diameter | 8 mm (0.315 in) |

| Thread Size | 3/8-24 UNF |

| Total Length | 1 meter |

| Connector Type | Standard male connector with connector protector |

| Armor | No (unarmored configuration) |

| Target Material | Calibrated for 4140 steel or similar conductive material |

| Sensing Range | -2 to -18 V DC linear output (typical) |

| Frequency Response | 0 Hz to 10 kHz |

| Material | Stainless steel body with polymer-insulated tip |

| Ingress Protection | IP68 |

| Operating Temperature | -35°C to +177°C (-31°F to +351°F) |

| Humidity Tolerance | 0% to 95% RH (non-condensing) |

| Weight | 0.323 kg |

| Compliance | API 670 compliant, RoHS, CE marked |

Product Applications

The 330101-00-20-10-11-05 proximity probe is primarily used for non-contact measurement of shaft displacement, vibration, and axial position in critical machinery across industries. Key applications include:

-

Steam and Gas Turbines – Monitoring shaft position and radial vibration for trip or alarm functions.

-

Centrifugal Compressors – Tracking rotor dynamics and detecting surge or unbalance.

-

Electric Motors and Generators – Verifying proper alignment and bearing performance.

-

Industrial Pumps – Ensuring mechanical health and preventing unplanned shutdowns.

-

Gearboxes and Fans – Monitoring gear mesh dynamics and rotational behavior.

-

Marine and Offshore Equipment – Offering robust sensing even in humid and corrosive environments.

Product Advantages

-

Reliable Performance in Harsh Environments

The IP68-rated design, with stainless steel construction, offers long-term stability in high humidity, dust, or oil-prone settings. -

High Accuracy Sensing

Calibrated for precise detection of shaft movement with excellent linearity over its operating range. -

Wide Operating Temperature Tolerance

Designed to perform under extreme temperature conditions encountered in industrial and energy generation environments. -

Compact and Modular Design

Easy to install and maintain. Modular system design allows flexible combination with extension cables and Proximitor sensors. -

Field Proven Technology

Based on decades of field application data and refined engineering, this probe series is trusted by leading OEMs and operators. -

Unarmored Configuration

Suitable for environments where flexibility is needed without sacrificing durability, or where protective conduit is already in place. -

API 670 Compliance

Meets globally recognized standards for critical machinery monitoring.

Frequently Asked Questions (FAQ)

-

What is the 330101-00-20-10-11-05 proximity probe used for?

It is designed for non-contact monitoring of vibration and shaft position in rotating machinery. -

Is this probe armored?

No, this particular model is an unarmored configuration. -

Can I use this probe in a high-temperature environment?

Yes, it operates up to +177°C (+351°F). -

How do I install this probe?

It is mounted via its threaded 3/8-24 UNF body into a probe mounting bracket or sleeve near the shaft being monitored. -

Does it comply with API 670?

Yes, it is compliant with the API 670 standard for condition monitoring systems. -

Is it compatible with older Bently Nevada systems?

Yes, it is backward compatible with 3300 XL extension cables and Proximitor sensors. -

What is the linear sensing range?

The probe typically offers a 2 mm linear range from -2 to -18 VDC output. -

Is the probe tip replaceable?

No, the tip is sealed and integrated; replacement requires changing the entire probe. -

What kind of material should the shaft be for optimal calibration?

It is calibrated for use with 4140 steel, which is the standard in most rotating machinery. -

How should I store unused probes?

Store in a cool, dry environment, away from magnetic fields or corrosive chemicals.

Related Models from the 3300 XL Series

| Model Number | Description | Tip Diameter | Cable Length | Mounting Thread |

|---|---|---|---|---|

| 330101-00-19-10-02-05 | 3300 XL 8 mm Probe, armored, 19 in | 8 mm | 10 ft | 3/8-24 UNF |

| 330101-00-23-10-11-05 | 3300 XL 8 mm Probe, unarmored, 23 in | 8 mm | 10 ft | 3/8-24 UNF |

| 330103-00-05-10-11-00 | 3300 XL 5 mm Probe, unarmored | 5 mm | 10 ft | M10 x 1 |

| 330104-00-20-10-11-00 | 3300 XL 11 mm Probe, 20 in, unarmored | 11 mm | 10 ft | 1/2-20 UNF |

| 330171-00-10-10-02-05 | 3300 XL Reverse Mount Probe | 8 mm | 10 ft | Reverse Thread |

| 330106-05-30-10-02-05 | 3300 NSv Probe (narrow tip for small installations) | 5 mm (NSv) | 10 ft | 1/4-28 UNF |

Popular Bently Nevada Models

| Model Number | Description | Application | Series |

|---|---|---|---|

| 3500/22M | Keyphasor Module | Rotation speed & phase detection | 3500 Series |

| 3500/42M | Proximitor Seismic Monitor | Shaft and casing vibration monitoring | 3500 Series |

| 3500/60 | Temperature Monitoring Module | Process and bearing temperature tracking | 3500 Series |

| 330180-91-00 | Extension Cable, 91 ft | Signal transmission between probe/sensor | 3300 XL |

| 330850-50-05 | Proximitor Sensor (5 m cable) | Signal conversion for proximity systems | 3300 XL |

| 991-06-XX-01-00 | Velocity Seismoprobe | Vibration monitoring in compressors/motors | Seismoprobe Series |

Excellent PLC

Excellent PLC