| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

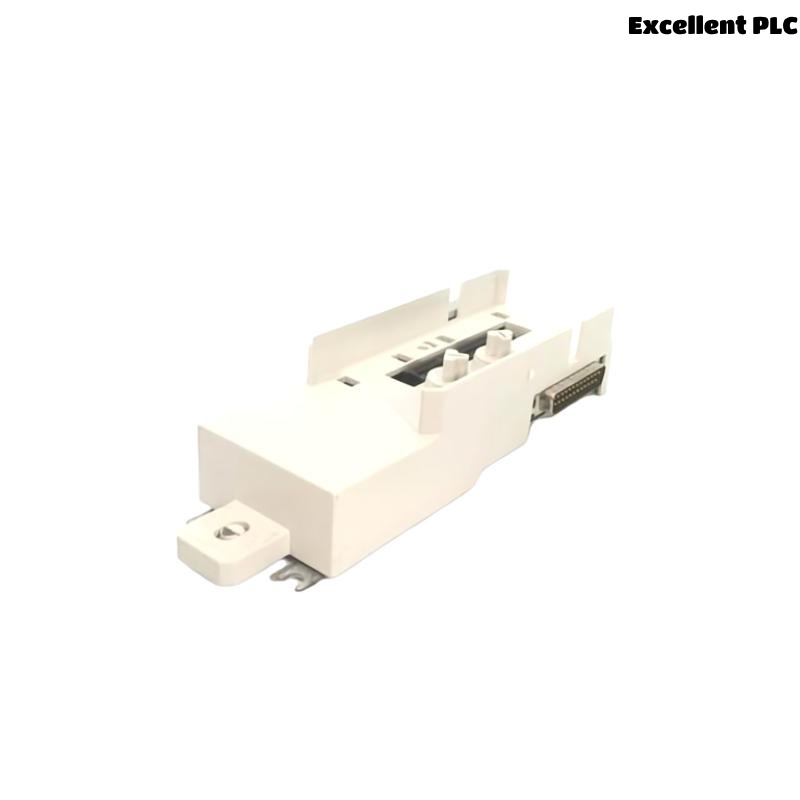

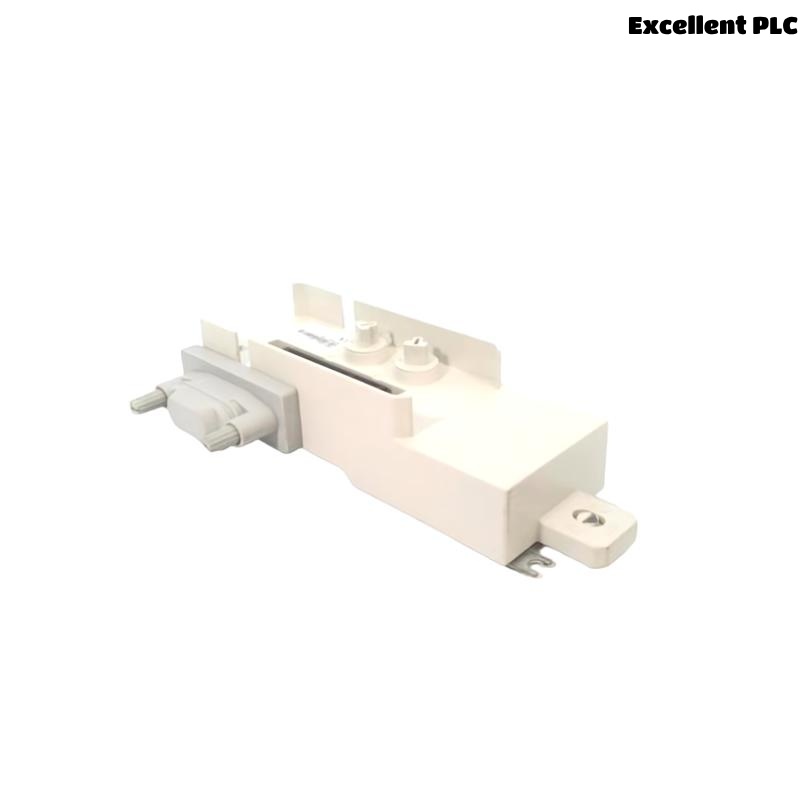

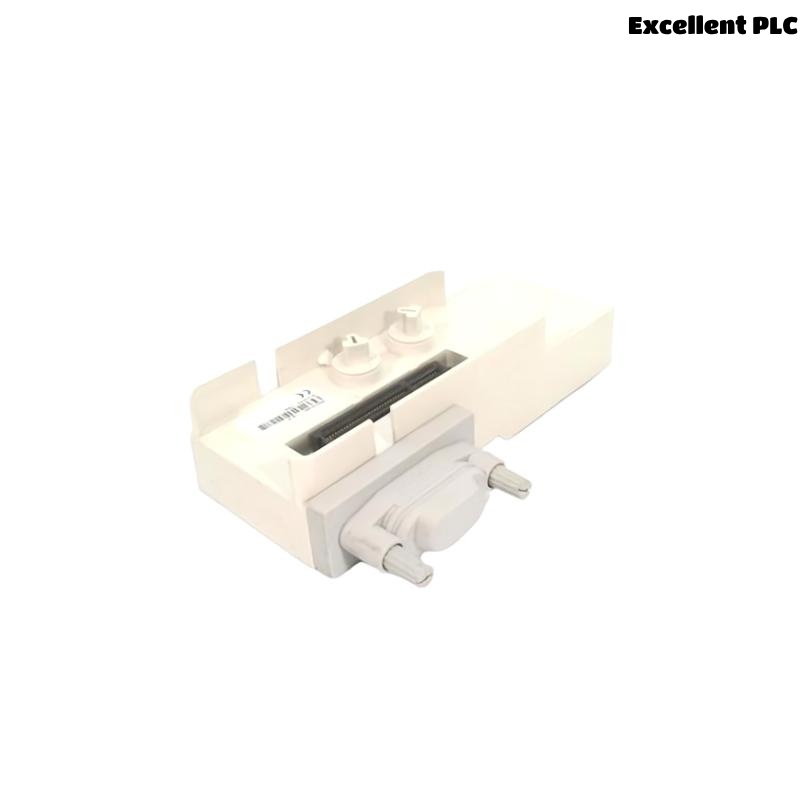

The ABB TP858 Baseplate (Part Number: 3BSE018138R1) is an essential component of ABB’s AC 800M and S800 I/O system architecture, serving as a mounting and interface foundation for communication modules such as the CI858 and CI858A. This baseplate is critical for maintaining physical and electrical connectivity between communication modules and the rest of the I/O and control infrastructure.

Designed with industrial robustness in mind, the TP858 ensures stable module integration, efficient signal transmission, and proper grounding. It facilitates communication in PROFIBUS DP networks and integrates seamlessly into System 800xA environments. The baseplate includes front connectors, status LEDs, and a backplane bus, ensuring dependable performance and fast installation.

Product Specifications

| Parameter | Details |

|---|---|

| Manufacturer | ABB |

| Model Number | TP858 |

| Part Number | 3BSE018138R1 |

| Product Type | Baseplate / Communication Interface Module Base |

| Compatibility | CI858, CI858A Communication Modules |

| System Integration | System 800xA, AC 800M Controllers |

| Fieldbus Support | PROFIBUS DP |

| Connector Type | 9-pin D-sub PROFIBUS connector (DB9) |

| Power Supply | Powered via CI module or system backplane |

| Mounting Type | DIN rail |

| Material | Industrial-grade thermoplastic |

| LED Indicators | Power, Communication, and Fault indicators |

| Operating Temperature | -25°C to +70°C |

| Storage Temperature | -40°C to +85°C |

| Ingress Protection | IP20 (when mounted in cabinet) |

| Dimensions (W × H × D) | 420 x 320 x 60 mm |

| Weight | 0.65 kg |

| Compliance | CE, RoHS, IEC/EN 61131-2 |

Product Applications

The ABB TP858 Baseplate plays a critical role in various industrial automation environments by providing a reliable foundation for communication and signal exchange. Key application areas include:

-

Process Automation Systems

Acts as a backbone for communication modules within distributed control systems (DCS). -

Manufacturing Facilities

Facilitates network communication between controllers and remote I/O units in automated production lines. -

Power and Utility Plants

Ensures dependable data exchange in substations and turbine control systems. -

Oil and Gas Industries

Supports real-time control and data acquisition in harsh environments, especially for PROFIBUS-based control architectures. -

Chemical and Petrochemical Plants

Ensures secure and fault-tolerant signal flow within safety-critical processes. -

Water Treatment Plants

Integrated into SCADA systems for relay and valve control across distributed network zones.

Product Advantages

-

Seamless Integration

Fully compatible with ABB’s CI858/CI858A modules and System 800xA for quick deployment. -

Robust Construction

Built from high-grade materials that withstand demanding industrial conditions. -

Compact and Efficient

Space-saving design with streamlined installation onto DIN rails. -

Stable Communication Support

Designed to maintain signal integrity and ensure consistent PROFIBUS connectivity. -

Pre-configured Interfaces

Reduces commissioning time with built-in connectors and easy-access terminals. -

Clear Diagnostics

LED indicators assist in real-time monitoring and fault detection. -

Enhanced Safety

Offers proper grounding and electrical isolation to protect both users and equipment. -

Low Maintenance

Long product lifespan with minimal wear-and-tear components. -

Flexible Deployment

Can be used in both centralized and distributed I/O architectures. -

ABB System Compatibility

Guaranteed performance within the broader ABB automation ecosystem.

Frequently Asked Questions (FAQ)

-

Q: What communication modules are supported by the TP858 baseplate?

A: It supports ABB CI858 and CI858A communication interface modules. -

Q: Can TP858 be used in non-ABB systems?

A: It is designed specifically for ABB AC 800M and System 800xA environments and may not be compatible with third-party platforms. -

Q: What communication protocol is TP858 used for?

A: It supports PROFIBUS DP for industrial communication. -

Q: How is the TP858 mounted?

A: It is designed for DIN rail mounting inside control cabinets. -

Q: Does the TP858 require external power?

A: It receives power from the CI858/CI858A communication module or the system backplane. -

Q: Are there LED indicators on the baseplate?

A: Yes, TP858 includes status LEDs for power, communication, and fault conditions. -

Q: What is the ingress protection rating of TP858?

A: It has an IP20 rating when installed inside an enclosure. -

Q: What is the typical operating temperature range?

A: It operates between -25°C and +70°C. -

Q: What kind of connectors are available on the TP858?

A: It features a standard DB9 PROFIBUS connector for communication. -

Q: Is TP858 hot-swappable?

A: No, modules should be replaced only when the power is off to avoid damage.

Recommended Related Models (Same Series or Related Use)

| Model | Description | Application | Dimensions (mm) |

|---|---|---|---|

| CI858 | Communication Interface Module, PROFIBUS DP | Used with TP858 baseplate | 45 × 186 × 130 |

| CI858A | Enhanced Communication Interface, PROFIBUS | Successor to CI858, with TP858 | 45 × 186 × 130 |

| TU830V1 | Terminal Unit for S800 I/O Modules | I/O interface with signal wiring | 110 × 119 × 103 |

| TP830 | Baseplate for S800 I/O | For CI854, CI855 modules | 116 × 119 × 103 |

| TP857 | Baseplate for CI857 Communication Module | AC 800M integration | 116 × 119 × 103 |

| TU810V1 | Compact Terminal Unit | DIN rail mount, I/O wiring | 116 × 119 × 103 |

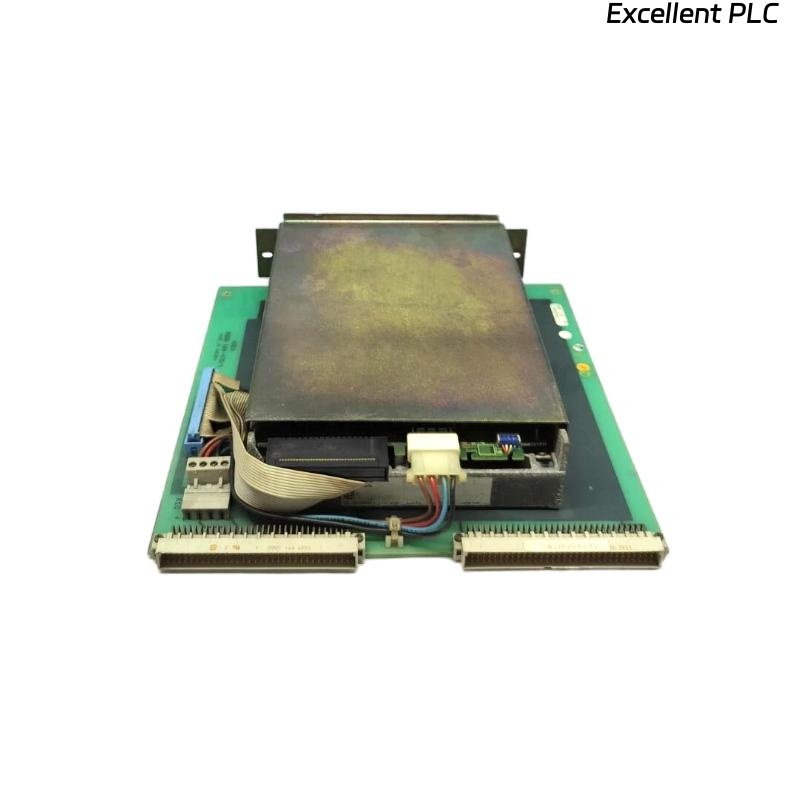

Popular ABB Models (High Demand, Cross-Series)

| Model | Description | Type | Key Feature |

|---|---|---|---|

| AC800M PM891 | High-performance Controller Unit | CPU Controller | Redundancy, SIL3, fast processing |

| CI854A | PROFIBUS DP Communication Interface Module | Communication Module | Dual PROFIBUS support |

| AI810 | Analog Input Module, 8 ch, 0–20 mA | Analog I/O | Precision current input |

| DO810 | Digital Output Module, 16 ch, 24 V DC | Digital Output | Current sourcing, fast switching |

| TU840 | Extended I/O Terminal Unit | Terminal Unit | Simplified wiring and diagnostics |

| CP600 HMI Panel | Control Panel for Operator Interface | HMI/Display | Touchscreen, high-resolution display |

Excellent PLC

Excellent PLC