| Company Information | ||||||||

| sales@xmjzjsgs.com | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

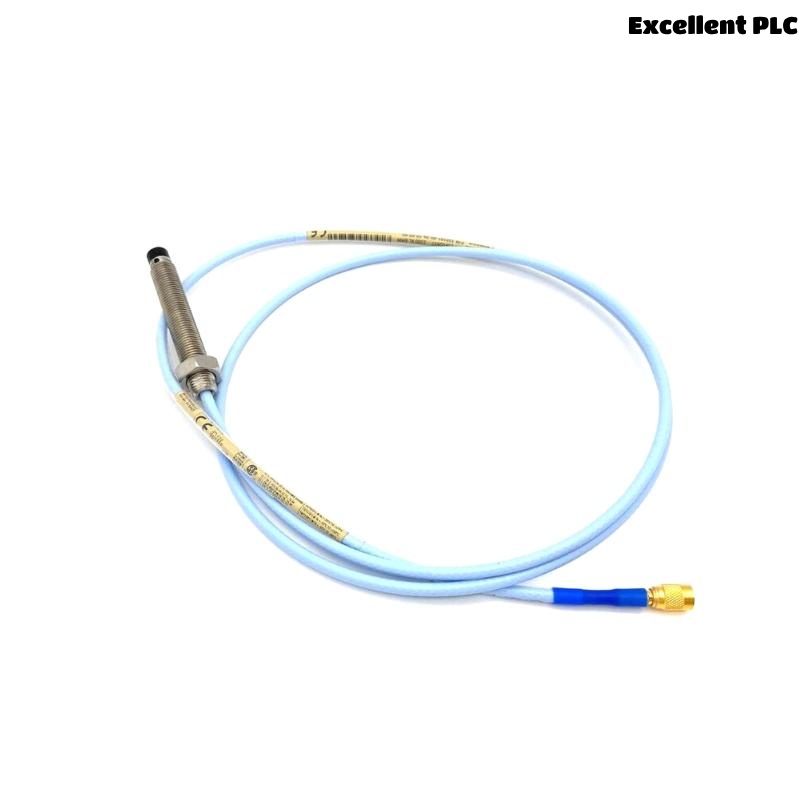

The Bently Nevada 330103-03-10-10-02-00 is a high-precision proximity probe from the widely acclaimed 3300 XL series. This probe is specifically engineered for demanding industrial applications where accurate shaft displacement and vibration monitoring are critical to machinery performance and reliability. Featuring an 8mm probe tip diameter and an integral 1 meter cable, this model employs proven eddy current technology to deliver non-contact measurements that form the foundation of effective condition monitoring and predictive maintenance programs.

With its stainless steel construction and ability to operate across a wide temperature range, the 330103-03-10-10-02-00 is suitable for continuous monitoring of steam and gas turbines, compressors, pumps, motors, and other rotating equipment. Its rugged design ensures long service life even in harsh environments characterized by heat, dust, moisture, and vibration.

Used globally across power generation, oil & gas, petrochemical, and heavy industries, this probe is a trusted component in critical machinery protection systems.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | 330103-03-10-10-02-00 |

| Probe Tip Diameter | 8 mm |

| Total Length | 1 meter |

| Probe Type | Eddy current proximity probe |

| Operating Temperature Range | -40°C to +120°C |

| Probe Body Material | Stainless steel |

| Connector Type | Integral cable |

| Weight | 0.323 kg |

| Frequency Response | DC to 25 kHz |

| Measuring Range | Up to 1.5 mm (depending on setup) |

| Electrical Interface | 2-wire shielded cable |

Applications

-

Steam and Gas Turbines: Accurate monitoring of shaft vibration and displacement helps prevent catastrophic failures caused by misalignment or imbalance.

-

Compressors: Identifies early signs of bearing degradation, shaft instability, or misalignment that could compromise efficiency.

-

Generators: Monitors rotor position and movement to maintain reliable power generation.

-

Pumps: Detects axial and radial shaft displacement to prevent seal wear, impeller damage, or bearing failure.

-

Motors and Gearboxes: Provides data for predictive maintenance by detecting abnormal vibration and shaft movement trends.

-

Industrial Rotating Machinery: Deployed in industries like petrochemical, pulp & paper, mining, and manufacturing where continuous machine health monitoring is essential.

Product Advantages

-

Precision Monitoring: The 8mm probe tip diameter provides highly accurate displacement readings critical for condition monitoring.

-

Extended Cable Length: The 1 meter integral cable ensures flexibility in installation and signal integrity over long distances.

-

Rugged Construction: Stainless steel body provides excellent resistance to harsh environments, including exposure to dust, oil, and moisture.

-

Wide Temperature Range: Capable of operating reliably from -40°C to +120°C, suitable for extreme industrial environments.

-

Non-Contact Measurement: Eddy current technology ensures wear-free operation, reducing maintenance needs and improving long-term reliability.

-

Consistent Performance: Delivers stable and noise-free signals, essential for effective vibration and displacement monitoring.

-

Low Maintenance Requirements: The robust build minimizes the need for recalibration or frequent maintenance checks.

-

Easy System Integration: Compatible with Bently Nevada 3300 series monitoring systems as well as other industry-standard vibration monitoring platforms.

-

Global Industry Standard: Used by leading operators worldwide for critical machinery protection and predictive maintenance.

Frequently Asked Questions (FAQ)

-

What does the Bently Nevada 330103-03-10-10-02-00 proximity probe measure?

It measures the displacement and vibration of rotating machinery shafts using eddy current, non-contact sensing technology. -

How long is the integral cable for this model?

The cable is 1 meter long, providing flexibility for various installation scenarios. -

What is the operating temperature range of this probe?

The probe operates reliably between -40°C and +120°C. -

Is this probe compatible with non-Bently Nevada monitoring systems?

Yes, while optimized for Bently Nevada 3300 series systems, it can also work with other compatible vibration monitoring equipment. -

How is this probe typically installed?

It is usually installed in threaded probe holders mounted in the bearing housing or machine casing, with the tip facing the shaft. -

What is the measuring range of this probe?

Up to 1.5 mm, depending on system configuration. -

How often should this probe be inspected or calibrated?

Routine visual inspections during plant shutdowns are recommended; calibration is rarely needed due to the non-contact design. -

What industries use this probe the most?

Power generation, oil & gas, chemical processing, pulp & paper, and heavy manufacturing industries. -

What kind of movement can this probe detect?

It can detect both axial and radial shaft movements, depending on probe placement. -

Why choose the 3300 XL series over other proximity probes?

The 3300 XL series is known for industry-leading reliability, accurate measurements, long service life, and proven performance in critical machinery applications worldwide.

Recommended Related Models (Same Series or Similar)

| Model Number | Probe Tip Diameter | Cable Length | Notes |

|---|---|---|---|

| 330103-00-13-05-02-00 | 8 mm | 5 meters | Standard cable length |

| 330103-00-15-10-02-00 | 8 mm | 10 meters | Similar length, alternate config |

| 330103-00-11-05-02-00 | 5 mm | 5 meters | Smaller tip for compact areas |

| 330103-00-25-05-02-00 | 8 mm | 5 meters | Medium-length option |

| 330103-00-13-20-02-00 | 8 mm | 20 meters | Extended cable length |

| 330103-00-12-10-02-00 | 12 mm | 10 meters | Larger tip for heavy machinery |

Popular Bently Nevada Models (Same Brand)

| Model Number | Description | Application |

|---|---|---|

| 330130-00-40-00-00-00 | 3300 XL Monitor | Proximity and vibration monitoring system |

| 330103-00-12-10-02-CN | 8 mm probe, 10m cable | For heavy industrial applications |

| 330108-00-04-05-02-00 | 5 mm probe, 5m cable | For general machinery monitoring |

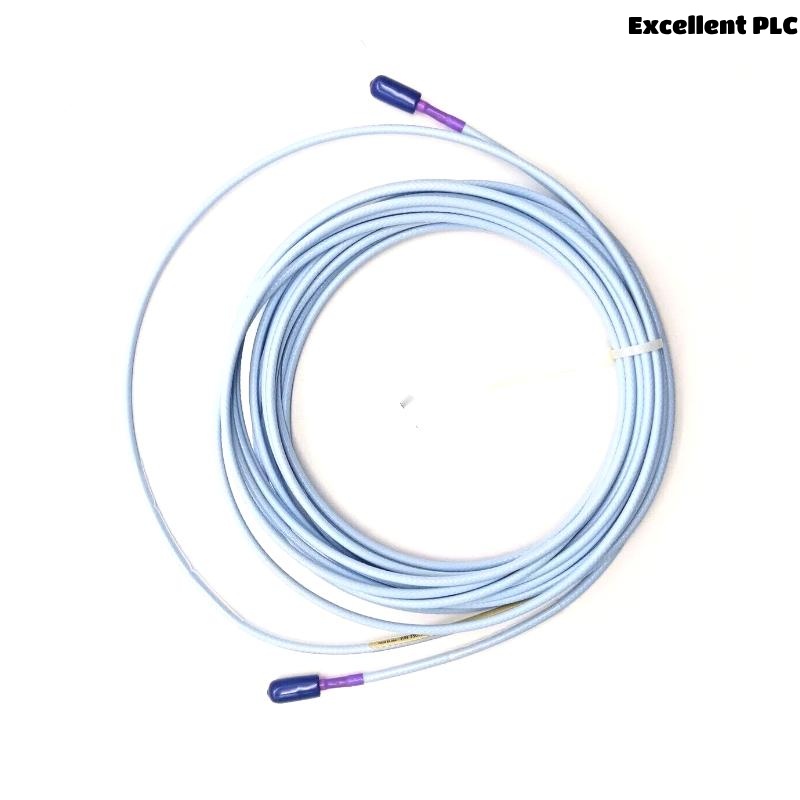

| 330090-00-03-05-00-00 | Replacement sensor cable | Spare part or repair cable |

| 330199-00-01-00-00-00 | Proximitor Sensor Module | Signal conditioning module |

| 330103-00-13-05-02-01 | 8 mm probe, 5m cable with enhanced temp rating | High-temperature applications |

Excellent PLC

Excellent PLC