| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

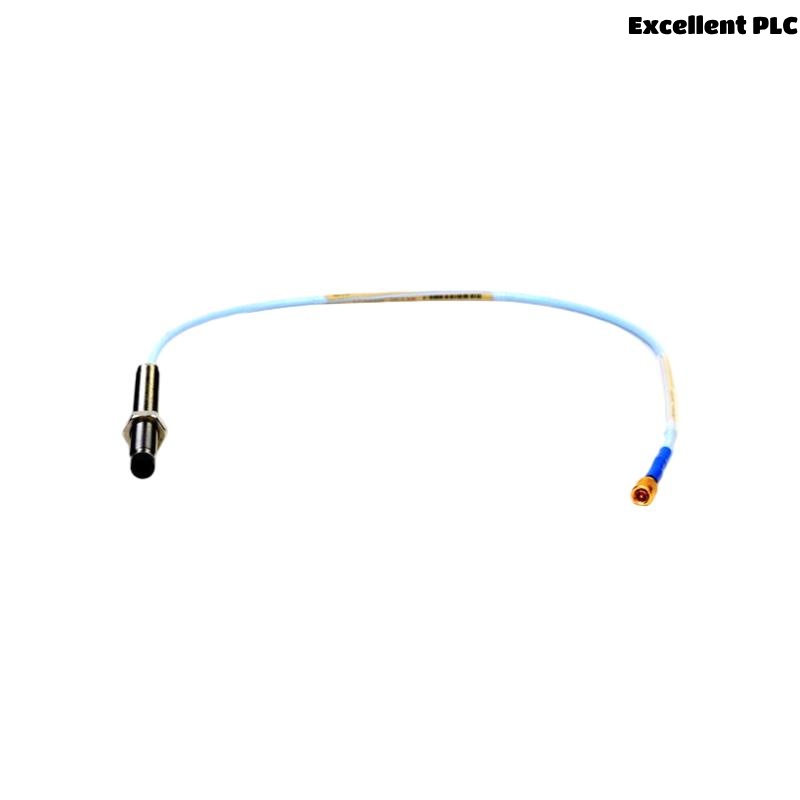

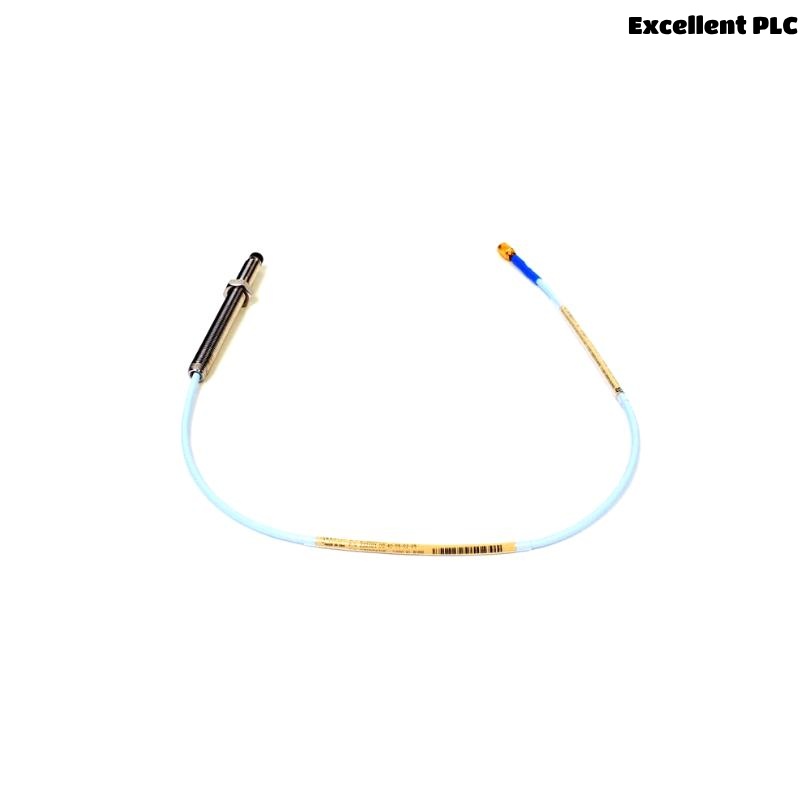

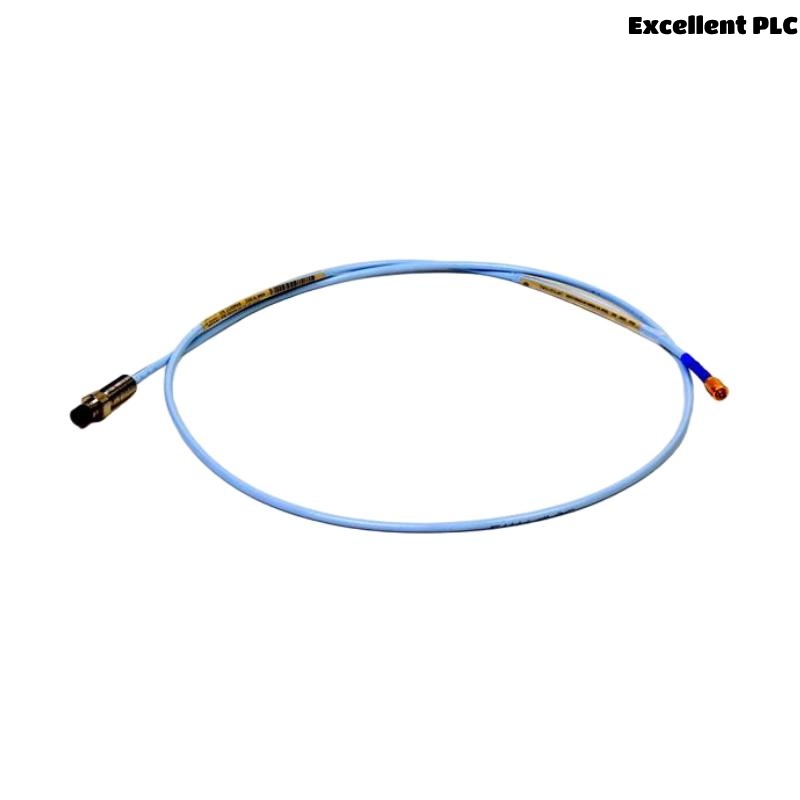

The Bently Nevada 330101-00-40-10-01-05 is a high-performance 3300 XL 8 mm Proximity Probe designed for industrial vibration monitoring and condition-based monitoring of rotating machinery. The probe is integral to Bently Nevada’s 3300 XL Series of machinery protection and condition monitoring equipment. With its precision-engineered design, the 3300 XL proximity probe provides high accuracy and reliability in measuring the displacement of rotating shafts, which is critical in detecting early signs of machinery failure.

This 8 mm proximity probe is known for its versatility and wide-ranging application in industries such as power generation, oil and gas, and heavy manufacturing. The 3300 XL series probes are widely regarded for their robust construction, making them capable of handling harsh environmental conditions, such as extreme temperatures, vibrations, and potential exposure to hazardous materials.

Product Parameters

| Parameter | Specification |

|---|---|

| Model | 3300 XL 8 mm Proximity Probe |

| Part Number | 330101-00-40-10-01-05 |

| Total Length | 1.0 meter |

| Weight | 0.323 kg |

| Diameter | 8 mm |

| Operating Temperature | -40°C to +120°C |

| Mounting Style | Threaded Mount |

| Cable Length | 1.0 meter |

| Sensing Range | ± 2.0 mm |

| Frequency Response | DC to 10 kHz |

| Shock Resistance | 200 g for 11 ms pulse |

| Vibration Resistance | 10 g peak (0-2000 Hz) |

Product Applications

The Bently Nevada 330101-00-40-10-01-05 3300 XL 8 mm Proximity Probe is used across various industries for vibration monitoring and machinery protection. It is ideal for applications that involve rotating equipment, where monitoring shaft displacement is critical. Some key applications include:

-

Power Generation

Used in power plants to monitor turbines, generators, and compressors, providing early detection of vibration and misalignment issues. -

Oil and Gas

Applied to monitor pumps, compressors, and motors in oil and gas extraction and processing plants. The probe ensures machinery reliability, reducing the risk of downtime due to failure. -

Manufacturing

In heavy manufacturing plants, the 3300 XL Proximity Probe is used to monitor motors, bearings, and other rotating equipment for vibrations, enabling proactive maintenance and reducing the likelihood of unexpected shutdowns. -

Mining

Monitors crushers, conveyors, and other mining machinery, ensuring continuous operation in tough working conditions and preventing potential equipment failures. -

Water Treatment

The probe is used in monitoring pumps and motors in water treatment plants, ensuring operational efficiency and the early detection of mechanical issues. -

HVAC Systems

In large HVAC systems, the proximity probe monitors fans, compressors, and blowers, helping to maintain system performance and efficiency.

Product Advantages

-

High Precision

The 3300 XL 8 mm Proximity Probe provides accurate shaft displacement measurements, crucial for detecting misalignments, imbalance, and mechanical wear in rotating machinery. -

Robust Construction

Designed to operate in harsh industrial environments, this probe can withstand extreme temperatures (-40°C to +120°C), vibrations, and mechanical shocks, making it suitable for a variety of applications. -

Easy Installation

The probe comes with a threaded mounting style that allows for easy installation and integration into existing machinery setups. -

Extended Sensing Range

The probe has a sensing range of ±2.0 mm, enabling it to detect even the slightest changes in shaft position, which is critical for early fault detection. -

Wide Frequency Response

With a frequency response from DC to 10 kHz, the 3300 XL Proximity Probe can monitor a broad spectrum of vibrations, making it adaptable to many machinery types. -

Durability

The probe’s robust construction ensures it can survive the harshest industrial conditions, including exposure to chemicals, extreme temperatures, and heavy vibration. -

High Shock Resistance

Capable of withstanding shocks up to 200 g for 11 ms pulses, this probe is built to perform reliably even in environments subject to frequent mechanical impacts. -

Improved System Reliability

The 3300 XL Proximity Probe is a key component in ensuring the operational reliability of industrial machinery by providing continuous condition monitoring, thus preventing unexpected downtime. -

Compact Design

Its compact size (8 mm diameter) makes the 3300 XL Proximity Probe easy to integrate into space-constrained environments without compromising performance. -

Proactive Maintenance

By monitoring vibrations and displacement, this probe allows for predictive maintenance, helping operators address potential issues before they lead to costly failures or downtime.

Frequently Asked Questions (FAQ)

-

Q: What is the function of the 3300 XL 8 mm Proximity Probe?

A: The probe measures shaft displacement in rotating machinery, helping to detect misalignments, imbalance, and wear before they lead to failures. -

Q: What is the total length of the 3300 XL Proximity Probe?

A: The total length of the 3300 XL 8 mm Proximity Probe is 1.0 meter. -

Q: What is the weight of this proximity probe?

A: The 3300 XL Proximity Probe weighs 0.323 kg. -

Q: What is the sensing range of the 3300 XL Proximity Probe?

A: The probe has a sensing range of ±2.0 mm. -

Q: What type of environments is the 3300 XL Proximity Probe suitable for?

A: It is designed for use in harsh industrial environments, withstanding extreme temperatures, vibrations, and mechanical shocks. -

Q: What is the frequency response of the 3300 XL Proximity Probe?

A: The probe has a frequency response from DC to 10 kHz. -

Q: Can the 3300 XL Proximity Probe be used in hazardous environments?

A: Yes, the probe is designed to operate reliably in hazardous and challenging environments, such as oil & gas plants and heavy manufacturing. -

Q: How is the 3300 XL Proximity Probe mounted?

A: The probe is mounted using a threaded mounting style, ensuring secure installation. -

Q: What is the shock resistance of the 3300 XL Proximity Probe?

A: The probe is shock-resistant up to 200 g for 11 ms pulses. -

Q: Is the 3300 XL Proximity Probe suitable for predictive maintenance?

A: Yes, the probe is ideal for predictive maintenance as it allows for continuous monitoring of machinery and early detection of potential issues.

Recommended Models (Same Series or Related)

| Model | Description | Cable Length | Connector Type | Application |

|---|---|---|---|---|

| 330901-00-32-05-02-05 | 3300 XL extension cable, shielded, right angle | 0.5 meter | Right-angle coaxial | Sensor extension in confined spaces |

| 330901-00-32-05-02-CN | 3300 XL extension cable, shielded, right angle | 0.5 meter | Right-angle coaxial | China variant for local compliance |

| 330901-00-32-10-02-00 | 3300 XL extension cable, shielded, straight | 1.0 meter | Straight coaxial | General vibration monitoring |

| 330901-00-32-05-01-00 | 3300 XL extension cable, low-noise type | 0.5 meter | Coaxial | Industrial sensor connection |

| 330901-00-32-10-01-00 | 3300 XL extension cable, high-flex, shielded | 1.0 meter | Coaxial | Dynamic machinery vibration monitoring |

| 330901-00-32-15-02-05 | 3300 XL extension cable, extra shielded variant | 1.5 meters | Shielded coaxial | Harsh environment applications |

Popular Models (Same Brand)

| Model | Description | Cable Length | Connector Type | Application |

|---|---|---|---|---|

| 330901-00-12-10-01-00 | 3300 XL extension cable, 3-slot shielded | 1.0 meter | Miniature coaxial | Vibration monitoring and sensor extension |

| 330901-00-15-05-01-00 | 3300 XL extension cable, rugged build | 0.5 meter | Miniature coaxial | Proximity probe extension in harsh areas |

| 330901-00-15-05-02-05 | Extension cable with right-angle connector | 0.5 meter | Right-angle coaxial | Tight-space vibration sensing applications |

| 330901-00-10-05-01-00 | Low-noise extension cable, standard type | 0.5 meter | Coaxial | General-purpose industrial monitoring |

| 330901-00-20-10-02-00 | High-flex cable for dynamic environments | 1.0 meter | Coaxial | Rotating machinery monitoring systems |

| 330901-00-25-05-01-00 | Shielded extension cable for EMI zones | 0.5 meter | Coaxial | Use in electrically noisy environments |

Excellent PLC

Excellent PLC