| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Description

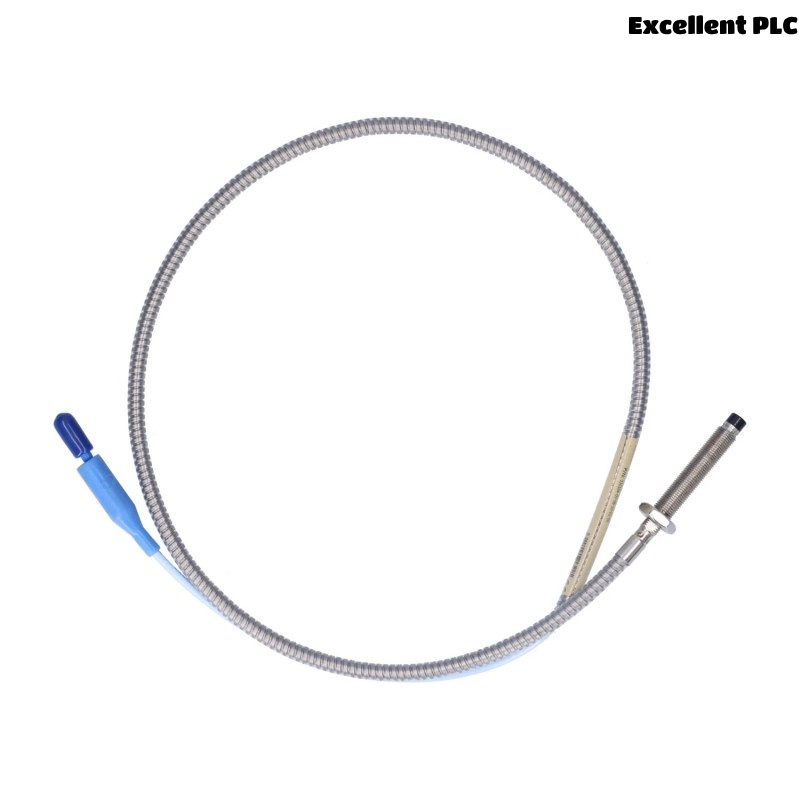

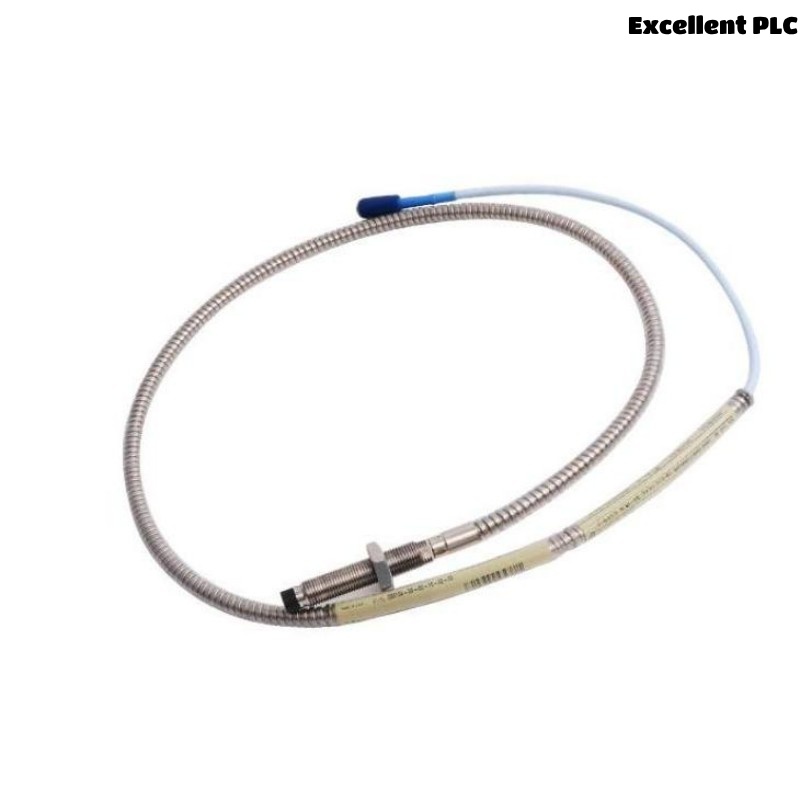

The Bently Nevada 330104-00-15-10-02-CN is part of the 3300 XL 8 mm proximity transducer system, designed for accurate and reliable vibration and position measurements in rotating machinery. It includes an armored M10x1 threaded 8 mm probe with 1.5-meter total length, compatible with XL and non-XL Proximitor systems.

Applications

-

Radial and axial vibration monitoring in turbines and compressors

-

Shaft position and Keyphasor measurements

-

Fluid-film bearing machinery monitoring

-

Overspeed protection systems

Product Advantages

-

Robust Design: Patented TipLoc and CableLoc ensure high pull strength and mechanical durability

-

Environmental Resistance: Optional FluidLoc and ClickLoc connectors offer superior sealing and corrosion resistance

-

Interchangeability: Compatible with other 3300 XL and non-XL components without field calibration

-

High Precision: Meets API 670 standards for linear range and accuracy

-

Flexible Mounting: Supports DIN and panel mounting

Technical Specifications

| Parameter | Value |

|---|---|

| Probe Type | 8 mm, M10x1 thread, armored |

| Total Length | 1.0 meter |

| Weight | 0.323 kg |

| Linear Range | 0.25 mm to 2.3 mm (10 to 90 mils) |

| Output Sensitivity | 7.87 V/mm (200 mV/mil) ±5% |

| Frequency Response | 0 to 10 kHz, +0/-3 dB |

| Probe Tip Material | PPS (Polyphenylene sulfide) |

| Case Material | AISI 304 Stainless Steel |

| Cable Type | Armored FEP, 75Ω triaxial |

| Min. Cable Bend Radius | 25.4 mm (1 in) |

| Operating Temperature (Probe) | -52°C to +177°C |

| Operating Temperature (Cable) | -52°C to +177°C |

| Compliance | API 670, CE, ATEX, IECEx, RoHS, SIL 2/3 |

FAQs

Q1: What is the main use of the 330104-00-15-10-02-CN probe?

A1: It is used for precise vibration and shaft position monitoring on critical rotating equipment.

Q2: Can this probe be used without an extension cable?

A2: Yes, this 1.0-meter version does not require an extension cable.

Q3: What is the output signal format?

A3: The system provides a voltage output directly proportional to shaft movement.

Q4: Is the probe compatible with other 3300 series components?

A4: Yes, it is backward-compatible with non-XL 3300 5 mm and 8 mm systems.

Q5: What is the standard gap voltage for installation?

A5: The recommended gap voltage is -9 Vdc (approx. 1.27 mm).

Q6: Is armor mandatory for installation?

A6: Not mandatory, but the armored version adds protection in harsh environments.

Q7: What is the probe’s resistance to environmental contaminants?

A7: With FluidLoc and ClickLoc features, it resists oil ingress and corrosion effectively.

Q8: Is recalibration needed when replacing components?

A8: No, components are fully interchangeable without bench calibration.

Q9: Can it be installed on small-diameter shafts?

A9: It is recommended for shaft diameters of 50.8 mm (2 in) or larger.

Q10: Is this probe suitable for use in hazardous areas?

A10: Yes, it meets ATEX, IECEx, and CSA certifications for hazardous zones.

Related Bently Nevada Series Models

| Model | Thread Type | Length | Cable Type | Weight |

|---|---|---|---|---|

| 330104-00-06-10-02-00 | M10x1 | 0.6 m | Armored | 0.290 kg |

| 330104-00-10-10-02-00 | M10x1 | 1.0 m | Armored | 0.323 kg |

| 330104-00-20-10-02-00 | M10x1 | 2.0 m | Armored | 0.410 kg |

| 330101-00-10-10-02-00 | 3/8-24 UNF | 1.0 m | Armored | 0.320 kg |

| 330103-00-10-10-02-00 | M10x1 (metric) | 1.0 m | Unarmored | 0.300 kg |

| 330105-02-12-10-02-00 | 3/8-24 UNF | 1.0 m | Reverse Mount | 0.320 kg |

Popular Bently Nevada Models

| Model | Product Type | Function | Key Feature |

|---|---|---|---|

| 3300 XL 5 mm Probe | Proximity Probe | Tight space monitoring | Smaller tip size (5 mm) |

| 330180-50-05 | Proximitor Sensor | Signal conditioning | Panel mount, 5 m system |

| 330130-030-00-00 | Extension Cable | Signal extension | 3.0 m, standard cable |

| 3500/42M | Vibration Monitor Module | Seismic & Prox sensor input | Buffered output, Keyphasor |

| 3500/22M | Transient Data Interface | Dynamic signal output | Communication to external tools |

| 3500/20 | Rack Interface Module | Rack power and configuration | Supports System 1 integration |

Excellent PLC

Excellent PLC