| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

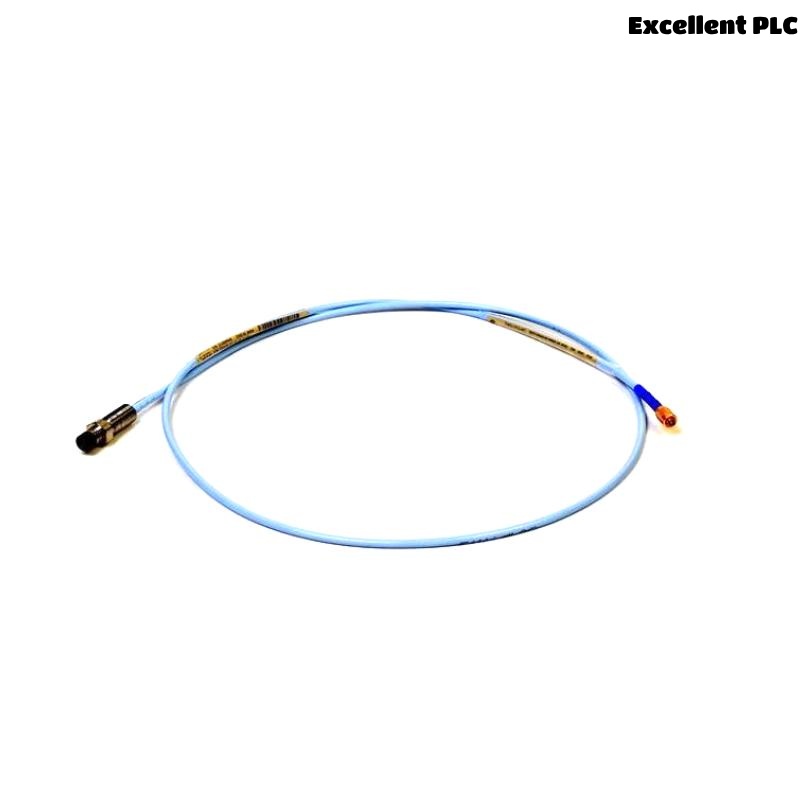

The Bently Nevada 330103-07-12-10-02-00 3300 XL 8mm Proximity Probe is a highly precise and rugged sensor engineered for the accurate measurement of shaft position and vibration in rotating machinery. As part of the widely respected 3300 XL 8mm series, this proximity probe provides operators with critical data required for protecting equipment, optimizing performance, and reducing unplanned downtime.

This probe is trusted across industries including power generation, oil & gas, petrochemicals, pulp & paper, and marine, making it one of the most popular solutions in industrial condition monitoring and machinery protection systems worldwide.

Product Specifications

| Specification | Details |

|---|---|

| Model | 330103-07-12-10-02-00 |

| Series | 3300 XL 8mm Proximity Probes |

| Manufacturer | Bently Nevada (a Baker Hughes business) |

| Sensing Range | 0 to 2 mm (80 mils) |

| Linear Range | 0.25 mm to 2 mm (10 mils to 80 mils) |

| Non-linearity | ±0.75% of full-scale range |

| Probe Tip Diameter | 8 mm |

| Total Length | 1 meter |

| Thread Type | 3/8-24 UNF |

| Probe Body Material | Stainless Steel |

| Cable Jacket Material | Polyethylene (PE) or optional FEP |

| Operating Temperature (Probe) | -35°C to +177°C |

| Operating Temperature (Cable) | -51°C to +177°C |

| System Compatibility | Bently Nevada 3300 XL Drivers & Monitors |

| Compliance | API 670 compliant |

| Weight | 0.323 kg |

Applications

The Bently Nevada 330103-07-12-10-02-00 Proximity Probe is designed for demanding industrial environments where accurate and continuous monitoring of shaft vibration and position is essential. It is widely used in:

-

Power Generation

Monitoring shaft position and vibration in steam turbines, gas turbines, and hydroelectric units. -

Oil & Gas

Providing critical data for the protection of compressors, pumps, and motors used in upstream, midstream, and downstream sectors. -

Petrochemical & Chemical Processing

Monitoring high-speed rotating equipment in hazardous environments for machinery protection. -

Pulp & Paper

Tracking vibration and wear in large paper machines and high-speed rollers. -

Steel & Metal Processing

Used on rolling mills, motors, gearboxes, and heavy-duty rotating equipment. -

Marine & Offshore

Monitoring engines, propulsion systems, and critical auxiliary rotating equipment on ships and offshore platforms.

Advantages

The 330103-07-12-10-02-00 8mm Proximity Probe offers numerous advantages that make it the preferred choice in industrial condition monitoring:

-

Field-Proven Reliability

Trusted across millions of installations globally for its stable, long-term performance. -

API 670 Certified

Meets the API 670 standard, making it ideal for safety-critical monitoring systems. -

Flexible Installation

Etension cable allow versatile routing and installation. -

Exceptional Durability

Stainless steel housing and high-quality cable construction for use in the harshest environments. -

Wide Temperature Range

Operates reliably from -35°C to +177°C (probe), -51°C to +177°C (cable). -

Superior Accuracy and Stability

Offers excellent linearity, minimal drift, and highly accurate measurement of shaft position and vibration. -

Seamless Integration

Fully compatible with existing Bently Nevada 3300 XL drivers and monitors. -

Low Maintenance

Designed for long life with minimal need for recalibration, reducing maintenance costs.

FAQs

-

What is the sensing range of this probe?

0 to 2 mm (80 mils). -

What is the system length for the 330103-07-12-10-02-00 model?

The system includes a 1 meter total length. -

Is this model API 670 compliant?

Yes, it fully meets API 670 standards. -

What temperature extremes can the probe withstand?

The probe operates from -35°C to +177°C; the cable from -51°C to +177°C. -

Is the cable jacket chemical resistant?

Yes, with an optional FEP jacket available for chemically aggressive environments. -

What industries commonly use this probe?

Power generation, oil & gas, petrochemicals, pulp & paper, metals processing, and marine industries. -

What mounting thread is used?

3/8-24 UNF thread. -

Is this probe backward compatible with earlier Bently Nevada systems?

Yes, it is compatible with 3300 XL drivers and monitors. -

How frequently does the probe require recalibration?

The probe offers long-term stability with minimal drift, requiring little to no recalibration. -

What is the linear measurement range?

0.25 mm to 2 mm (10 mils to 80 mils).

Related Models

| Model | Description | Key Features |

|---|---|---|

| 330103-05-10-10-12-05 | 8mm Proximity Probe (5 m probe, 12 m cable) | Industry-standard, API 670 compliant |

| 330103-06-13-10-02-00 | 8mm Proximity Probe (6 m probe, 13 m cable) | Flexible installation, API 670 compliant |

| 330103-06-25-10-02-00 | 8mm Proximity Probe (6 m probe, 25 m cable) | Extended system length for large machines |

| 330104-00-10-10-02-05 | 11mm Proximity Probe | For larger shafts and greater clearances |

| 330105-02-12-10-02-05 | 25mm Proximity Probe | High-clearance large machinery monitoring |

| 330106-05-10-10-02-05 | NSv Narrow Surface Probe | Tight clearance installations |

Popular Models from Bently Nevada

| Model | Description | Key Features |

|---|---|---|

| 3300 XL 8mm Proximity Probes | Industry-standard proximity probes | API 670 compliant, accurate and robust |

| 3300 XL 11mm Proximity Probes | Larger probes for extended range | For larger gaps and shaft diameters |

| 3300 XL NSv Proximity Probes | Compact probes for restricted spaces | Designed for small shaft applications |

| 3500/42M Proximitor Monitor | Advanced proximity monitor | High-performance machinery protection |

| 330400 Velomitor Sensor Series | Velocity sensors for vibration monitoring | High accuracy, field-proven |

| 3500/22M Transient Data Interface | High-speed data interface for 3500 systems | Captures dynamic and transient machine data |

Excellent PLC

Excellent PLC