| Company Information | ||||||||

| sales@xmjzjsgs.com | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Overview

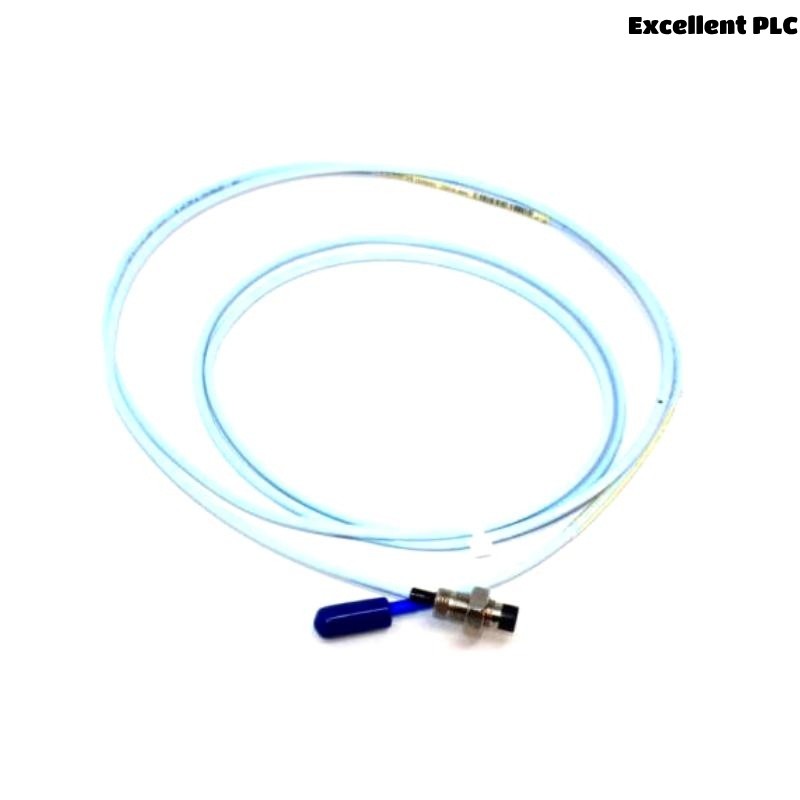

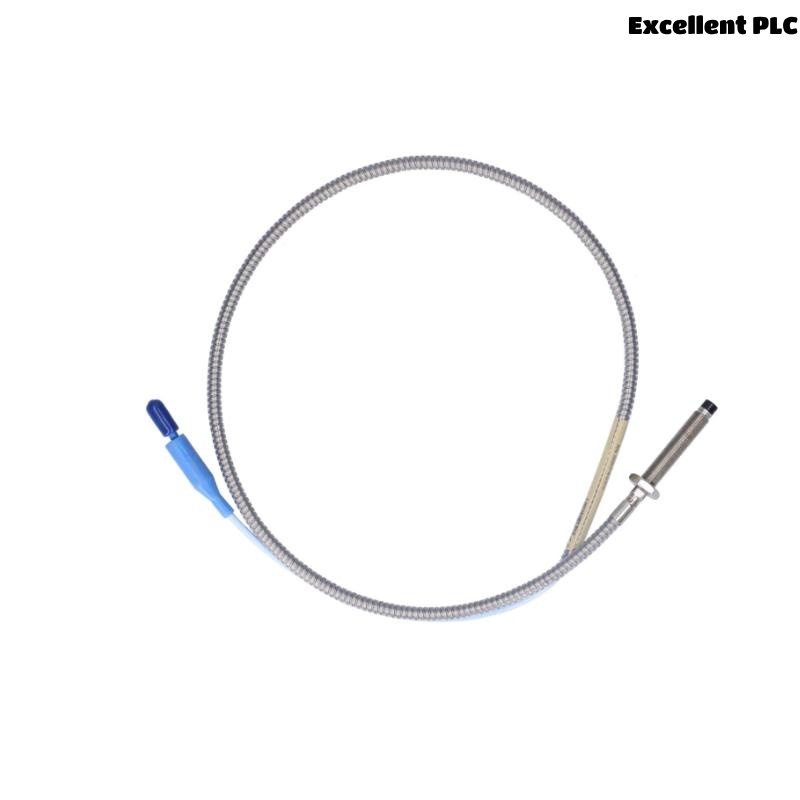

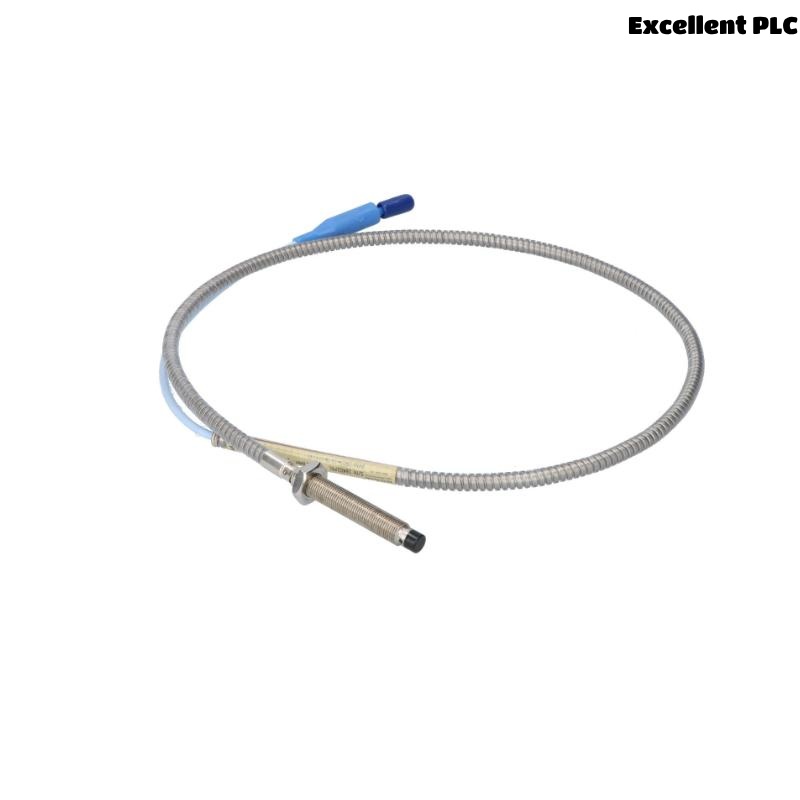

The Bently Nevada 330104-00-22-10-02-05 3300 XL 8 mm Proximity Probe is an industry-leading sensor designed to measure shaft vibration, relative position, and axial thrust in critical rotating machinery. Utilizing proven eddy current sensing technology, this probe forms part of the globally trusted 3300 XL series and delivers highly accurate, stable, and linear output signals, even under extreme operating conditions.

This particular configuration features a 1 meter probe cable length, non-armored construction, and an 8 mm probe tip, making it an ideal solution for applications requiring flexibility and excellent measurement performance.

Compatible with 3300 XL Proximitor Sensors and extension cables, the probe provides a consistent voltage output corresponding to shaft displacement. It is a vital component in machine protection and condition monitoring systems across industries like oil & gas, power generation, refining, chemicals, and heavy manufacturing.

Product Specifications

| Parameter | Specification |

|---|---|

| Model | 330104-00-22-10-02-05 |

| Product Type | 3300 XL 8 mm Proximity Probe |

| Sensing Technology | Eddy current, non-contact |

| Probe Tip Diameter | 8 mm |

| Probe Tip Material | Polyphenylene sulfide (PPS) |

| Thread Size | 3/8-24 UNF |

| Total Length | 1 meter |

| Cable Armor | Non-armored |

| Connector Type | Miniature coaxial connector |

| Target Material | 4140 steel (factory calibrated) |

| Measurement Range | 2 mm (80 mils), linear range |

| Scale Factor | 200 mV/mil (7.87 mV/μm) nominal |

| System Linear Range | 80 mils (2.0 mm) |

| Non-Linearity | ≤ ±0.75% of full scale (typical) |

| Frequency Response | 0 Hz to 10 kHz (±3 dB) |

| Operating Temperature (Probe) | -51 °C to +177 °C |

| Operating Temperature (System) | -35 °C to +120 °C |

| Humidity | 100% condensing, fully sealed |

| Shock / Vibration Tolerance | 10 g @ 10-2,000 Hz |

| Pressure Rating | 5 bar (sealed probe tip) |

| Certifications | CE, ATEX Zone 2, CSA, IECEx |

| Weight | 0.323 kg |

Applications

The 330104-00-22-10-02-05 proximity probe is used across a wide range of rotating machinery in industries that depend on high asset reliability and uptime:

-

Gas and Steam Turbines

Continuous monitoring of shaft vibration and thrust position to prevent costly failures. -

Compressors (Centrifugal and Reciprocating)

Real-time measurement of shaft movement and bearing health. -

Electric Motors

Detecting imbalance, misalignment, and degradation of motor components. -

Industrial Pumps

Providing early warnings of excessive vibration or mechanical wear in pump systems. -

Fans and Blowers

Ensuring smooth, vibration-free operation and extending equipment life. -

Gearboxes

Monitoring relative shaft position for improved gearbox health diagnostics. -

Critical Rotating Equipment in Oil & Gas, Power Plants, and Refineries

Preventing unplanned shutdowns and improving maintenance efficiency.

Product Advantages

-

Exceptional Measurement Accuracy

Delivers highly linear, low-noise signals — critical for protection systems. -

Non-Armored Cable for Flexibility

Simplified installation where armored protection is unnecessary. -

Broad Temperature Range

Operates reliably from -51 °C to +177 °C — ideal for demanding environments. -

Industry Certifications

Approved for use in hazardous zones (CE, ATEX Zone 2, CSA, IECEx). -

Rugged Design

Sealed construction ensures full performance in high humidity, vibration, and shock-prone locations. -

Compatible with Global Standards

Integrates seamlessly with 3300 XL Proximitor Sensors and legacy Bently Nevada systems. -

Low Maintenance

Designed for years of reliable service with minimal recalibration. -

Highly Versatile

Suitable for diverse rotating equipment across industries. -

Proven in the Field

Backed by thousands of installations worldwide. -

Optimized Cable Length (22 ft)

Provides flexibility for various mounting configurations.

Frequently Asked Questions (FAQ)

-

What equipment can this probe monitor?

It is suitable for turbines, compressors, motors, pumps, fans, gearboxes, and many other rotating machines. -

How does it measure shaft vibration?

It outputs a voltage that is linearly proportional to shaft-to-probe distance. -

What’s the advantage of using a non-armored cable?

Easier routing and installation in clean or controlled environments. -

What is the rated cable length for this model?

1 meter. -

What certifications does it have?

CE, ATEX Zone 2, CSA, and IECEx — safe for use in explosive and hazardous areas. -

Does it require periodic recalibration?

No — designed for long-term operation with excellent stability. -

Is it compatible with older Bently Nevada Proximitor units?

Yes — backward compatible with most legacy 3300 series systems. -

What is the probe’s linear measurement range?

80 mils (2.0 mm). -

Can this probe operate in extreme temperatures?

Yes — rated from -51 °C to +177 °C at the probe tip. -

What is the recommended shaft target material?

4140 steel, or material calibrated to match Bently Nevada’s factory standard.

Related Models from the Same Series or Category

| Model | Product Type | Cable Length | Armor Type | Dimensions & Weight |

|---|---|---|---|---|

| 330104-00-22-10-02-05 | 3300 XL 8 mm Probe | 22 ft (6.71 m) | Non-armored | 8 mm tip, ~0.58 kg |

| 330104-00-20-05-02-00 | 3300 XL 8 mm Probe | 20 ft (6.10 m) | Armored | 8 mm tip, ~0.60 kg |

| 330104-00-15-10-01-CN | 3300 XL 8 mm Probe | 15 ft (4.57 m) | Non-armored | 8 mm tip, ~0.50 kg |

| 330104-00-25-05-02-00 | 3300 XL 8 mm Probe | 25 ft (7.62 m) | Armored | 8 mm tip, ~0.65 kg |

| 330104-00-10-10-01-CN | 3300 XL 8 mm Probe | 10 ft (3.05 m) | Non-armored | 8 mm tip, ~0.45 kg |

| 330104-00-05-05-02-00 | 3300 XL 8 mm Probe | 5 ft (1.52 m) | Armored | 8 mm tip, ~0.40 kg |

Popular Models from Bently Nevada Product Line

| Model | Product Type | Application Area | Dimensions & Weight |

|---|---|---|---|

| 3500/22M | Transient Data Interface Module | Machine Protection Systems | ~0.80 kg |

| 3500/42M | Proximitor/Seismic Monitor | Shaft vibration, bearing wear | ~1.20 kg |

| 3500/33 | RTD/TC Temperature Monitor | Motor winding / bearing temp | ~1.10 kg |

| 330130-040-00-00 | 3300 XL 8 mm Extension Cable | Drives matching probes | ~0.30 kg |

| 330180-50-00 | 3300 XL Proximitor Sensor | Drives 3300 XL 8 mm probes | ~0.50 kg |

| 3500/15 | Power Supply Module | 3500 Series Rack | ~1.50 kg |

Excellent PLC

Excellent PLC