| Company Information | ||||||||

| sales@xmjzjsgs.com | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Description

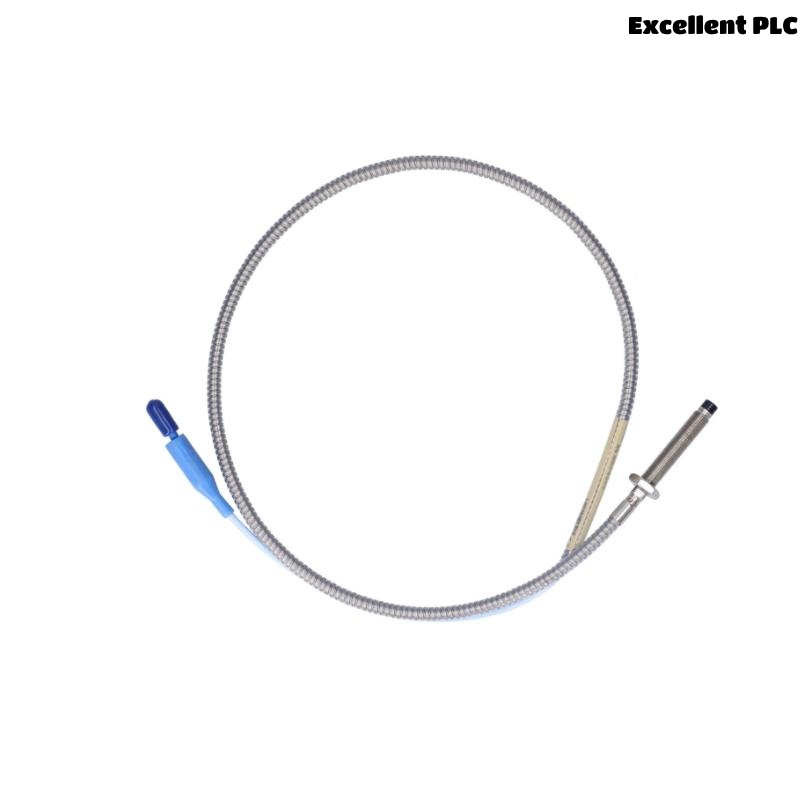

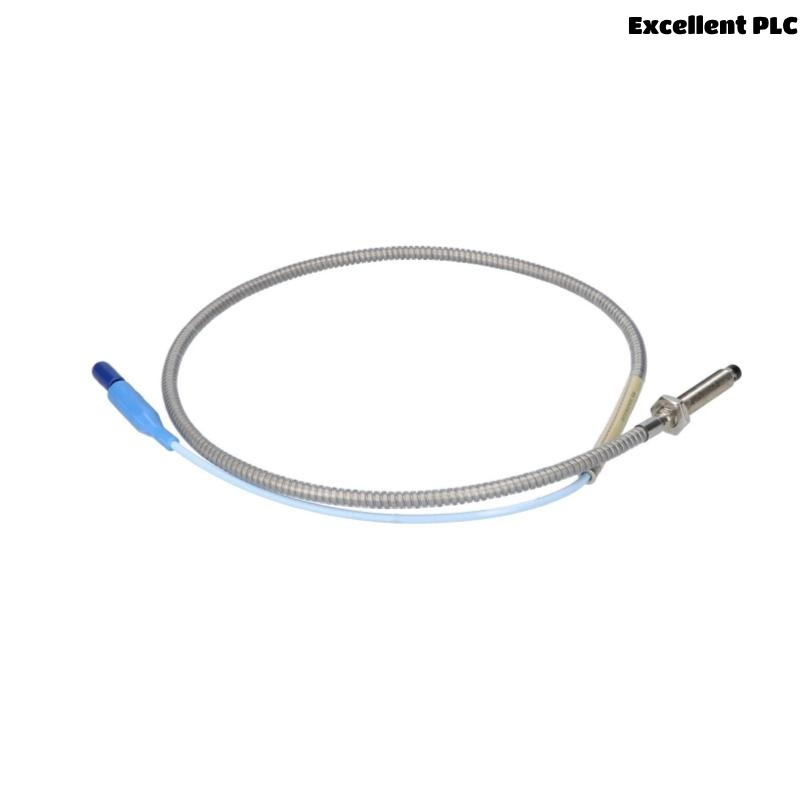

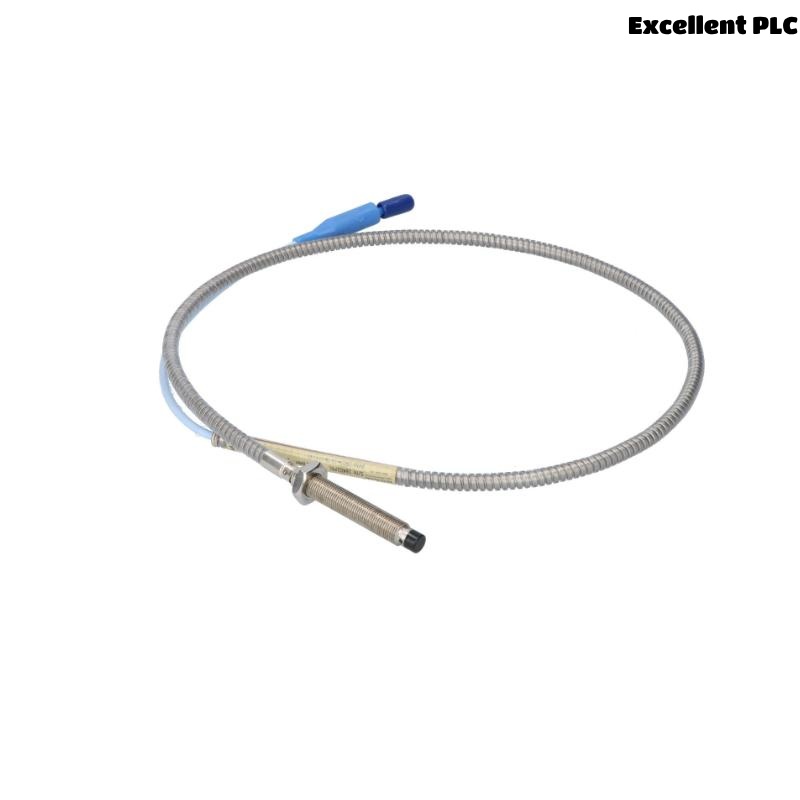

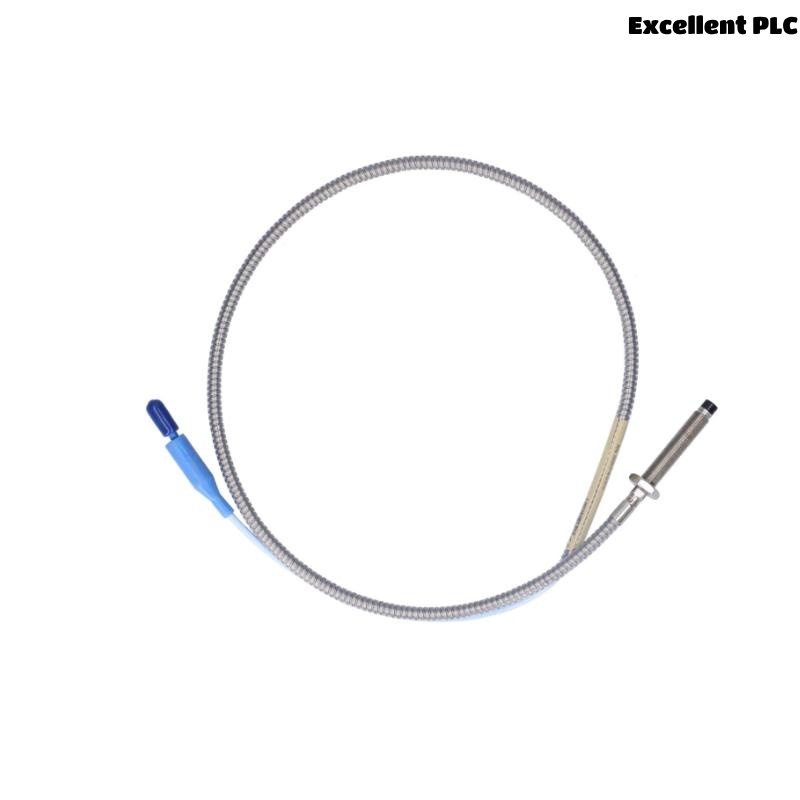

The Bently Nevada 330104-00-08-10-02-05 is a robust 8 mm proximity probe designed for precise static and dynamic measurements of shaft position and vibration. It forms part of the 3300 XL 8 mm Transducer System, including the probe, extension cable, and Proximitor sensor. The model is built with M10 x 1 metric threading and includes armor protection, ClickLoc connectors, and a 1.0-meter total length.

Applications

-

Shaft vibration and position monitoring on fluid-film bearing machines

-

Keyphasor reference and speed measurements

-

Turbomachinery overspeed and phase detection

-

Compressors, pumps, turbines, and motors

Product Advantages

-

API 670 compliance for linearity and temperature stability

-

Interchangeable components without field calibration

-

Armor design for protection in harsh environments

-

ClickLoc connectors ensure secure, tool-free installation

-

Extended temperature range options available

-

Improved EMI/RFI immunity

-

Optional FluidLoc cable prevents lubricant ingress

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | 330104-00-08-10-02-05 |

| Probe Tip Diameter | 8.0 mm |

| Thread Type | M10 x 1 (metric) |

| Total Length | 1.0 meter |

| Weight | 0.323 kg |

| Material | AISI 304 stainless steel with PPS tip |

| Temperature Range | –52°C to +177°C (standard), up to 218°C (ETR option) |

| Linear Range | 2 mm (0.25 to 2.3 mm gap) |

| Frequency Response | 0 to 10 kHz |

| Output Sensitivity | 7.87 V/mm (200 mV/mil) |

| Recommended Shaft Diameter | ≥ 50.8 mm (2 in), ≥ 76.2 mm (3 in) preferred |

| Connector Type | Miniature coaxial ClickLoc |

| Armor | Included (Flexible AISI 302/304 SST with FEP jacket) |

Frequently Asked Questions (FAQ)

Q1: What is the function of the 330104-00-08-10-02-05 probe?

A1: It measures shaft vibration and position by detecting distance changes to a rotating shaft.

Q2: Is this probe suitable for API 670 compliance?

A2: Yes, it fully complies with API 670 standards for vibration monitoring systems.

Q3: Can this probe be used with older Bently Nevada systems?

A3: Yes, it is backward compatible with non-XL 3300 series components.

Q4: What is the recommended gap voltage for installation?

A4: Approximately –9 Vdc, equating to a 1.27 mm (50 mil) gap.

Q5: What environments can this probe withstand?

A5: It is rated from –52°C to +177°C and is resistant to oil ingress when FluidLoc cable is used.

Q6: Does it require calibration before use?

A6: No, components are factory calibrated and fully interchangeable.

Q7: What’s the benefit of ClickLoc connectors?

A7: They provide secure, tool-free connections with a locking click.

Q8: Can I use this probe for high-speed turbines?

A8: Yes, it supports speed and Keyphasor measurements.

Q9: What is the probe cable’s pull strength?

A9: 330 N (75 lbf) due to the patented CableLoc design.

Q10: How does the armor help?

A10: It shields the cable from mechanical and environmental damage.

Related Bently Nevada 3300 XL Series Models

| Model Number | Thread Type | Total Length | Armor | Temp Range |

|---|---|---|---|---|

| 330101-00-08-10-02-05 | 3/8-24 UNF | 1.0 m | Yes | Std |

| 330103-00-04-10-02-00 | M10 x 1 | 1.0 m | No | Std |

| 330105-02-12-10-02-05 | 3/8-24 UNF | 1.0 m | No | Std |

| 330106-05-30-10-02-00 | M10 x 1 (Reverse) | 1.0 m | No | Std |

| 330192-00-08-10-02-05 | 3/8-24 UNF | 1.0 m | Yes | ETR |

| 330194-00-06-10-02-00 | M10 x 1 | 1.0 m | Yes | ETR |

Popular Bently Nevada Models

| Model Number | Product Type | Description | Weight | Length |

|---|---|---|---|---|

| 330104-00-08-10-02-05 | Proximity Probe | M10x1 armored probe with ClickLoc, 1m | 0.323 kg | 1.0 m |

| 330180-50-05 | Proximitor Sensor | Panel mount, 5m system | 0.246 kg | – |

| 330130-030-00-05 | Extension Cable | Standard 3.0 m with approvals | ~0.034 kg | 3.0 m |

| 3500/42M-01-00 | Proximitor Monitor Module | Vibration monitoring for radial/axial motion | – | – |

| 3500/22M-01-01-00 | Transient Data Interface | Condition monitoring interface | – | – |

| 3500/15-05-01-00 | Power Supply Module | Universal 120/240 VAC | – | – |

Excellent PLC

Excellent PLC