| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

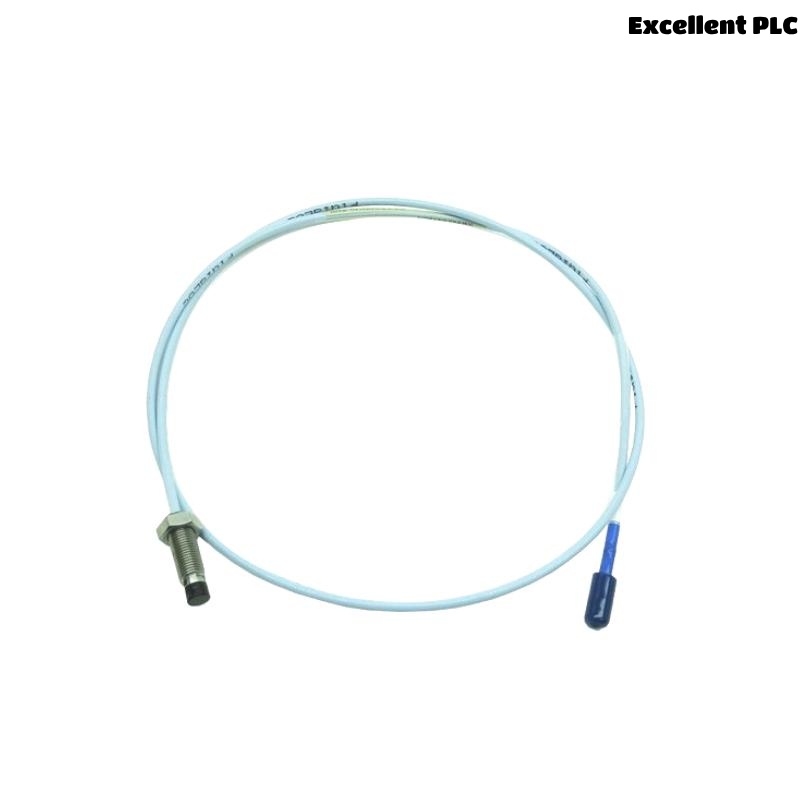

The Bently Nevada 330103-13-23-05-02-00 3300 XL 8mm Proximity Probe is a precision measurement sensor designed specifically for industrial machinery monitoring. As part of the renowned 3300 XL series, this probe delivers highly reliable and accurate displacement readings, critical for condition monitoring and predictive maintenance in rotating equipment. Built with robust materials and advanced sensing technology, the 3300 XL proximity probe ensures continuous performance even under harsh industrial environments.

Its 8mm probe length is optimal for detecting shaft vibrations and position variations, enabling early fault detection and protection of valuable assets. The model supports integration with Bently Nevada’s monitoring systems, making it a trusted choice for sectors requiring precision and durability.

Product Specifications

| Parameter | Details |

|---|---|

| Model Number | 330103-13-23-05-02-00 |

| Series | 3300 XL |

| Probe Type | Proximity Probe |

| Probe Length | 8 mm |

| Probe Diameter | 12.7 mm (0.5 inches) |

| Total Length | 0.5 meter |

| Operating Temperature | -40°C to 120°C (-40°F to 248°F) |

| Output Type | AC Voltage Signal |

| Sensor Element | Eddy Current |

| Housing Material | Stainless Steel |

| Connector Type | 2-pin military-style connector |

| Weight | 0.161 kg |

| Vibration Resistance | 10 g (20 Hz to 2 kHz) |

Applications

The 3300 XL 8mm Proximity Probe is widely used in industries that rely on rotating machinery, including:

-

Power Generation: Monitoring turbine shafts, generators, and motors to ensure operational stability.

-

Oil & Gas: Machinery protection in pumps, compressors, and drilling equipment.

-

Aerospace: Monitoring engine components and rotary equipment for early failure detection.

-

Manufacturing: Condition monitoring for high-speed spindles, gearboxes, and conveyor systems.

-

Mining & Metals: Monitoring crushers, mills, and conveyors in harsh environments.

-

Chemical Processing: Protection and condition monitoring of rotating pumps and agitators.

Advantages

-

High Accuracy: The probe’s eddy current sensing technology offers precise displacement measurement essential for predictive maintenance.

-

Robust Construction: Stainless steel housing and rugged design ensure long service life in extreme conditions.

-

Wide Operating Temperature Range: Functions reliably from -40°C up to 120°C, suitable for various industrial environments.

-

Interchangeability: Fully compatible with other 3300 XL series components for flexible system integration.

-

Ease of Installation: Compact size and standard connector simplify installation and replacement.

-

Reliable Signal Output: Produces a stable AC voltage signal for accurate data transmission.

-

Shock and Vibration Resistant: Designed to withstand high mechanical stresses, reducing downtime risks.

-

Long Cable Options: Available with extended cable lengths to suit different machine layouts.

Frequently Asked Questions (FAQ)

-

What is the main purpose of the 330103-13-23-05-02-00 probe?

It is designed to measure the displacement and vibration of rotating shafts, helping to monitor machinery health. -

Is this probe compatible with other Bently Nevada 3300 XL system components?

Yes, it is fully compatible with the 3300 XL monitoring system components. -

What kind of signal does this probe output?

It outputs an AC voltage signal corresponding to shaft displacement. -

Can the total length be customized?

Yes, while the total length is 0.5 meter, longer cables can be ordered based on application needs. -

What environmental conditions can this probe withstand?

It operates reliably in temperatures ranging from -40°C to 120°C and can resist shocks up to 100 g. -

How often should the probe be calibrated or serviced?

Calibration intervals depend on usage and environment but generally should be checked annually or during routine maintenance. -

Is the probe installation difficult?

No, the compact size and standard connector make installation straightforward for trained technicians. -

What happens if the probe cable is damaged?

Cable damage can affect signal quality; damaged cables should be replaced promptly to maintain measurement accuracy. -

Does this probe require external power?

The probe operates without external power, using the eddy current principle to generate its output. -

Can this probe detect shaft rub or misalignment?

Yes, by monitoring displacement and vibration patterns, it can help detect such mechanical issues early.

Related and Recommended Models

| Related Models (3300 XL Series) | Description |

|---|---|

| 330103-13-23-05-02-00 | 8mm Proximity Probe (Current Model) |

| 330101-00-44-10-02-05 | 8mm Proximity Probe, alternate config |

| 330102-13-23-05-02-00 | 12mm Proximity Probe |

| 330104-13-23-05-02-00 | 18mm Proximity Probe |

| 330109-00-00-10-05-02 | 8mm Probe with Integral Connector |

| 330130-00-00-00-10-02 | Probe Extension Cable |

| Popular Models from Bently Nevada Brand | Description |

|---|---|

| 330103-13-23-05-02-00 | 8mm Proximity Probe (Current Model) |

| 330101-00-44-10-02-05 | 8mm Proximity Probe |

| 330104-00-00-10-05-02 | 18mm Proximity Probe |

| 3500/05/01-01 | 3500 Series Monitor Module |

| 73011-00-00-10-00-00 | 3300 XL Monitor Amplifier |

| 330121-00-00-05-00-02 | Vibration Sensor |

Excellent PLC

Excellent PLC