| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

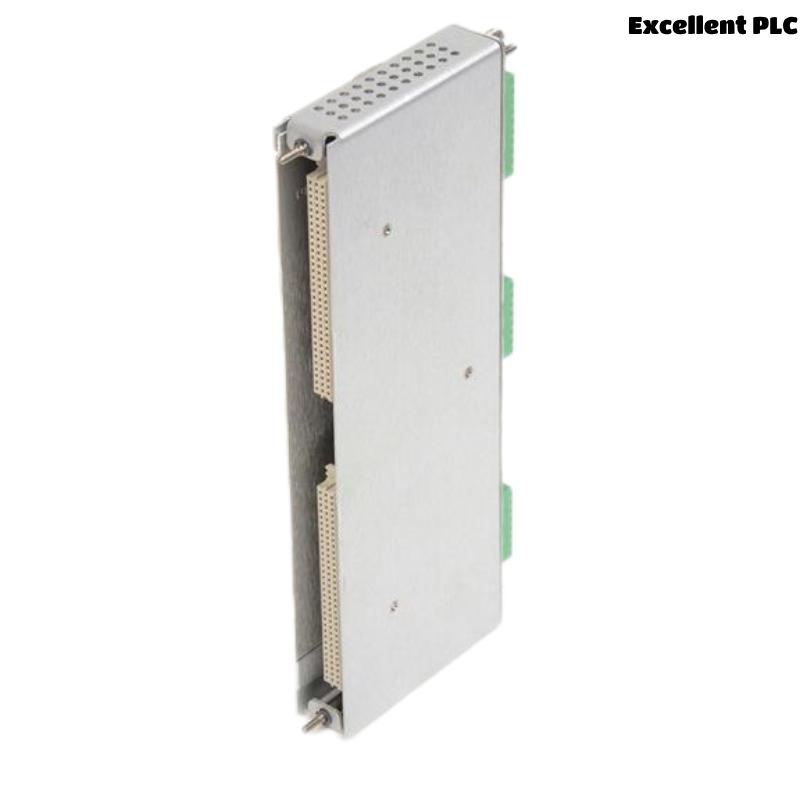

The Bently Nevada 3500/42M-07-00 138708-01 Absolute Shaft I/O module is a specialized device designed to monitor the rotational position and vibration of critical machinery components, particularly shaft positions. This module plays an essential role in condition monitoring systems, allowing engineers to track the precise position of rotating equipment in real time.

This module provides key measurements related to shaft angular displacement, enabling accurate monitoring of shaft alignment, misalignment, and potential failure points. By delivering continuous feedback on shaft movements, the 3500/42M-07-00 module helps prevent equipment damage due to rotational issues, reducing downtime and maintenance costs.

The 3500/42M-07-00 is part of the widely recognized Bently Nevada 3500 series, a comprehensive monitoring system designed for the most demanding industrial environments. This module’s integration with Bently Nevada’s other diagnostic equipment ensures an interconnected and robust monitoring setup for machine health.

Product Parameters

| Parameter | Value |

|---|---|

| Dimensions (L x W x H) | 241.3 × 24.4 × 99.1 mm |

| Weight | 0.2 kg |

| Operating Voltage | 24 V DC |

| Signal Output | 4-20 mA, 0-10 V |

| Temperature Range | -40°C to +85°C |

| Mounting Type | Rail-mounted |

| Input Type | Differential / Single-ended |

| Compliance | CE, UL certified |

Applications

The Bently Nevada 3500/42M-07-00 module is primarily used in industries where monitoring the position and movement of critical rotating components is essential. Here are some key applications:

-

Power Generation: The module is used to monitor the shaft position in turbines, compressors, and pumps, ensuring proper alignment and operation in power plants.

-

Oil & Gas: It is applied to monitor the shafts in drilling rigs, pumps, and compressors to detect misalignment and reduce the risk of damage in harsh operating conditions.

-

Manufacturing and Automation: In automated manufacturing systems, the module helps monitor the movement of critical machinery components, ensuring operational efficiency and preventing machinery breakdowns.

-

Mining: In mining operations, the module is used to monitor equipment such as crushers, grinders, and mills. Shaft position monitoring ensures the correct operation of these heavy-duty machines.

-

Transportation: The module is used in transportation systems, including marine and rail, to monitor the shaft alignment in engines, motors, and other critical systems, helping prevent failure and ensuring smooth operations.

-

Industrial Pumps and Motors: The device is critical in the monitoring of industrial pumps and motors, ensuring they maintain the correct shaft positioning and are operating within safe parameters.

Advantages

-

Precise Shaft Positioning: The 3500/42M-07-00 module provides highly accurate measurements of shaft positioning, helping to detect misalignment or abnormal movement, which can prevent mechanical failure.

-

Real-Time Monitoring: Continuous, real-time monitoring of rotating equipment allows for quick detection of any abnormal vibrations or positional deviations, enabling immediate corrective action.

-

Flexible Output Options: With both 4-20 mA and 0-10 V output options, the module can integrate seamlessly with a variety of control and monitoring systems.

-

Wide Temperature Range: The module operates effectively in harsh environments with a temperature range of -40°C to +85°C, making it suitable for use in power plants, refineries, and other demanding settings.

-

Space-Efficient Design: Compact dimensions (241.3 × 24.4 × 99.1 mm) and a light weight (0.2 kg) make the module ideal for installations with limited space.

-

Durability: Designed to withstand industrial conditions, the module is built to operate reliably in environments prone to vibration, dust, and extreme temperatures.

-

Easy Integration: The module is compatible with other Bently Nevada monitoring systems, allowing for easy integration into existing setups.

-

Compliance with Safety Standards: The module is CE and UL certified, ensuring it meets the highest standards for safety and reliability in industrial applications.

FAQs

-

What is the frequency range of the 3500/42M-07-00 module?

The module provides real-time monitoring of shaft positioning, specifically for critical machinery applications, though the exact frequency range is application-dependent. -

What is the weight of the 3500/42M-07-00 module?

The module weighs 0.2 kg, which makes it lightweight and easy to install in systems with limited space. -

What are the output options for the 3500/42M-07-00?

It supports 4-20 mA and 0-10 V outputs for integration with various control and monitoring systems. -

What is the operating temperature range for the module?

The module operates in a temperature range from -40°C to +85°C, suitable for harsh industrial environments. -

How does the 3500/42M-07-00 module monitor shaft positioning?

The module uses advanced sensors to detect angular displacement, allowing for accurate monitoring of shaft movements and alignment. -

Is the module compatible with other Bently Nevada systems?

Yes, the 3500/42M-07-00 module integrates seamlessly with other Bently Nevada monitoring systems. -

What industries use the 3500/42M-07-00 module?

It is widely used in power generation, oil & gas, mining, manufacturing, and transportation industries. -

Can the module detect both shaft misalignment and vibrations?

Yes, the module is capable of detecting both shaft misalignment and abnormal vibration, preventing costly machinery damage. -

What is the mounting type of the module?

The 3500/42M-07-00 is rail-mounted, making it easy to install and integrate into existing control systems. -

Is the module CE and UL certified?

Yes, it is CE and UL certified, ensuring it meets international safety and quality standards.

Recommended Models (Same Series or Related Models)

| Model | Description | Dimensions (L x W x H) | Weight |

|---|---|---|---|

| 3500/42M | Shaft monitoring module | 241.3 × 24.4 × 163.1 mm | 0.46 kg |

| 3500/41 | Vibration monitoring module | 241.3 × 24.4 × 163.1 mm | 0.46 kg |

| 3500/44 | Dynamic vibration monitor | 241.3 × 24.4 × 163.1 mm | 0.46 kg |

| 3500/45 | Rotor monitoring module | 241.3 × 24.4 × 163.1 mm | 0.46 kg |

| 3500/46 | Expansion module for seismic monitoring | 241.3 × 24.4 × 163.1 mm | 0.46 kg |

| 3500/47 | Temperature and vibration module | 241.3 × 24.4 × 163.1 mm | 0.46 kg |

Popular Bently Nevada Models

| Model | Description | Dimensions (L x W x H) | Weight |

|---|---|---|---|

| 3500/45-01-01 | Keyphasor® vibration monitor module | 150 x 120 x 90 mm | 1.2 kg |

| 3500/45-01-CN | Keyphasor® vibration monitor module (China version) | 150 x 120 x 90 mm | 1.2 kg |

| 3500/45-02-00 | Keyphasor® module with extended range and features | 150 x 120 x 90 mm | 1.3 kg |

| 3500/45-01-02 | Advanced Keyphasor® vibration monitoring module | 150 x 120 x 90 mm | 1.3 kg |

| 3500/45-02-01 | Enhanced Keyphasor® with diagnostic capabilities | 150 x 120 x 90 mm | 1.4 kg |

| 3500/45-02-CN | Keyphasor® module for China region with extended features | 150 x 120 x 90 mm | 1.3 kg |

Excellent PLC

Excellent PLC