| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

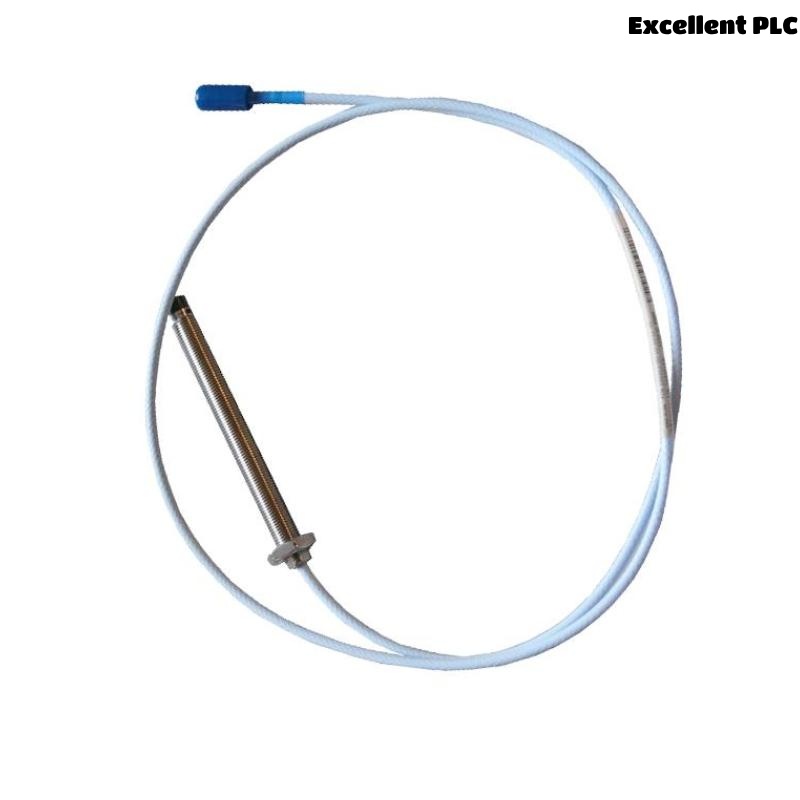

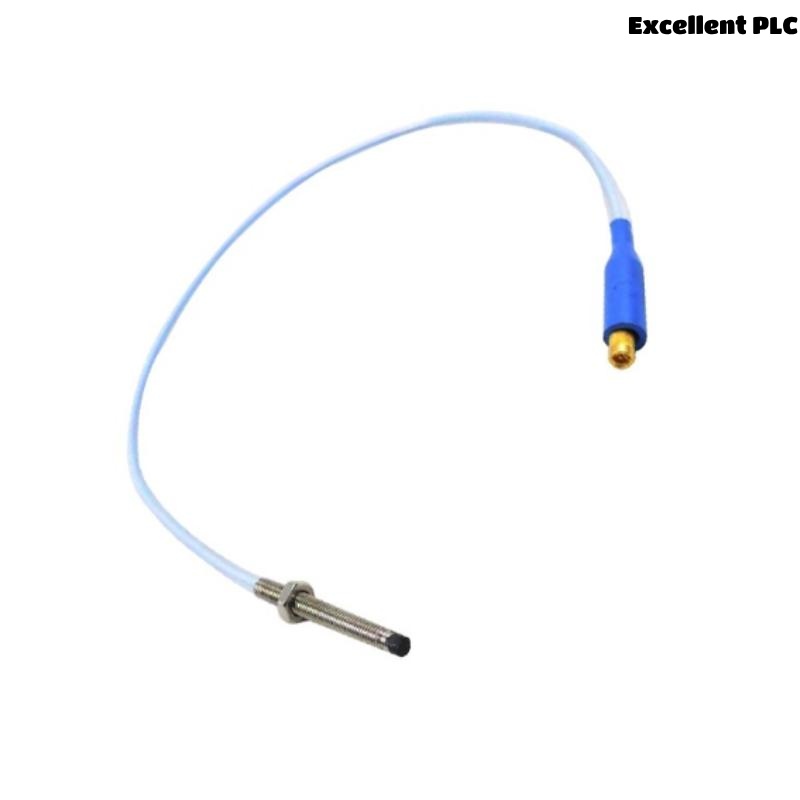

The Bently Nevada 330910-00-15-10-02-00 3300 NSv Proximity Probe is a precision measurement tool used for monitoring the displacement between a rotating shaft and its stationary housing in various industrial machinery. This sensor is a part of the 3300 NSv series of proximity probes, widely known for their reliability and high-performance capabilities. The probe is designed to provide accurate measurements of shaft displacement, which is crucial for the early detection of misalignment, vibration issues, and potential mechanical failure in rotating equipment.

This proximity probe is suitable for use in industries such as power generation, oil and gas, manufacturing, and water treatment, where precise machinery health monitoring is essential for avoiding unplanned downtime and ensuring the efficient operation of critical equipment. With a total length of 1 meter and a shipping weight of just 2 kg, this probe can be easily integrated into various industrial systems.

The 3300 NSv probe offers high accuracy and durability, even in challenging environments. It is equipped with advanced signal conditioning and uses a 4-20 mA output to provide reliable real-time feedback to control and monitoring systems.

Product Parameters

| Parameter | Specification |

|---|---|

| Model | 330910-00-15-10-02-00 |

| Total Length | 1 meter |

| Shipping Weight | 2 kg |

| Output Type | 4-20 mA Linear Output |

| Measurement Type | Shaft Displacement |

| Cable Length | 1 meter (standard) |

| Probe Diameter | 6.35 mm (1/4 inch) |

| Temperature Range | -40°C to +120°C |

| Maximum Vibration | 0.254 mm (0.010 inches) |

| Protection Rating | IP67 |

| Operating Pressure | 10 MPa (1450 psi) |

| Compliance | CE, UL, UL60950 |

Product Applications

The 3300 NSv Proximity Probe is ideal for a wide range of industrial applications where the accurate monitoring of rotating machinery is crucial for maintaining operational efficiency and safety. Common uses include:

-

Turbines and Compressors: The probe is used to monitor shaft displacement and vibration in turbines, helping detect misalignments, imbalance, and wear before they lead to system failure.

-

Electric Motors: It is used in electric motors to ensure that they are operating within tolerances and to prevent damage caused by misalignment.

-

Pumps: Used in critical pump systems to detect and correct issues such as shaft misalignment, which can cause wear and system inefficiency.

-

Generators: In power generation facilities, the probe is essential for monitoring the health of generators, ensuring that vibrations and shaft movement are within safe parameters.

-

Manufacturing Equipment: The probe is commonly found in automated manufacturing equipment, where it is used to monitor motors, conveyors, and other critical machinery.

-

Oil and Gas Industry: In this industry, the probe is used to monitor large rotating equipment such as blowers, pumps, and motors, ensuring the continuous and efficient operation of critical assets.

Product Advantages

-

High Accuracy: The 3300 NSv probe provides precise displacement measurements with a resolution capable of detecting the smallest deviations, enabling early detection of faults such as misalignment or bearing wear.

-

Durable Construction: Designed to withstand extreme operating conditions, the probe has a robust IP67 protection rating, making it resistant to dust and water ingress, and ensuring reliable performance in harsh environments.

-

Wide Temperature Range: The 3300 NSv probe operates effectively across a broad temperature range from -40°C to +120°C, making it ideal for use in extreme industrial environments.

-

Real-time Monitoring: With its 4-20 mA linear output, the probe allows for real-time data transmission to control and monitoring systems, ensuring prompt action can be taken if any anomalies are detected.

-

Easy Integration: The probe is designed for quick installation and is compatible with a variety of monitoring systems, reducing setup time and complexity.

-

Cost-Effective Maintenance: By providing early warning signs of mechanical issues, the 3300 NSv probe helps prevent costly repairs, reduce downtime, and extend the operational life of machinery.

-

Reliable Performance: The combination of high-precision sensing and a robust design ensures consistent and accurate performance over time, even in demanding industrial conditions.

Frequently Asked Questions (FAQs)

Q1: What is the total length of the 3300 NSv probe?

A1: The 3300 NSv probe has a total length of 1 meter.

Q2: What is the shipping weight of the 3300 NSv probe?

A2: The shipping weight of the probe is 2 kg.

Q3: What output type does the 3300 NSv probe use?

A3: The 3300 NSv probe uses a 4-20 mA linear output for signal transmission.

Q4: What is the maximum vibration the 3300 NSv probe can measure?

A4: The probe can measure up to 0.254 mm (0.010 inches) of vibration.

Q5: What is the temperature range for the 3300 NSv probe?

A5: The probe operates within a temperature range of -40°C to +120°C.

Q6: How is the 3300 NSv probe mounted?

A6: The probe can be easily integrated into existing monitoring systems using standard mounting techniques. It is typically installed along the shaft and connected to the monitoring system via a 1-meter cable.

Q7: What industries use the 3300 NSv proximity probe?

A7: The 3300 NSv probe is used across various industries, including power generation, oil and gas, manufacturing, water treatment, and more.

Q8: Can the 3300 NSv probe be used in hazardous environments?

A8: Yes, the probe is designed for use in harsh and hazardous environments, offering a robust construction that ensures its reliability in extreme conditions.

Q9: Is the 3300 NSv probe compatible with most monitoring systems?

A9: Yes, the 3300 NSv probe is designed to work with most industrial monitoring systems and provides a standard 4-20 mA output that is widely supported.

Q10: What are the key advantages of using the 3300 NSv probe?

A10: The key advantages include high precision, durability, real-time monitoring, wide temperature range, and cost-effective maintenance. It helps prevent unplanned downtime and enhances machine lifespan by detecting potential failures early.

Recommended Models

| Model | Description | Total Length |

|---|---|---|

| 330910-00-05-10-02-00 | Proximity Probe with standard cable length | 1 meter |

| 330910-00-10-10-02-00 | Extended length proximity probe | 2 meters |

| 330910-00-05-25-02-00 | High-pressure rated proximity probe | 1 meter |

| 330910-00-06-10-02-00 | Proximity probe for extreme temperature environments | 1 meter |

| 330910-00-05-15-02-00 | Shorter probe for tight spaces | 0.5 meters |

| 330910-00-07-10-02-00 | Heavy-duty proximity probe for large systems | 1 meter |

Popular Models from Bently Nevada

| Model | Description | Dimensions (mm) |

|---|---|---|

| 330909-00-99-10-02-00 | 3300 NSv velocity sensor, 10 m armored cable, high-precision | 70 x 19 x 24 |

| 330910-00-03-10-02-00 | 3300 NSv velocity sensor, 10 m cable, extended temperature range | 70 x 19 x 24 |

| 330910-00-05-05-02-CN | 3300 NSv velocity sensor, 5 m cable, Chinese version | 70 x 19 x 24 |

| 330909-00-99-05-02-00 | 3300 NSv velocity sensor, 5 m cable, armored, standard version | 70 x 19 x 24 |

| 330909-00-99-10-01-00 | 3300 NSv velocity sensor, 10 m cable, high-temperature rating | 70 x 19 x 24 |

| 330910-00-03-05-02-00 | 3300 NSv velocity sensor, 5 m cable, high-speed version | 70 x 19 x 24 |

Excellent PLC

Excellent PLC