| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

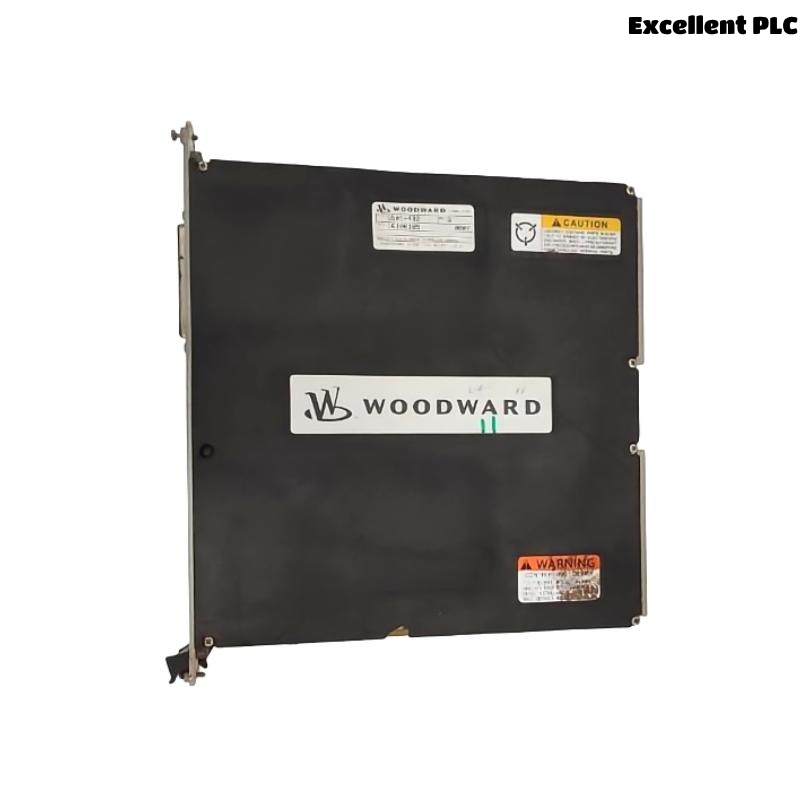

The Woodward 5501-432 Actuator Control Module is a precision-engineered digital device designed to provide reliable and efficient control of actuators in prime mover systems, such as engines, turbines, and compressors. As part of Woodward’s advanced digital control family, the 5501-432 integrates seamlessly into automated control environments requiring fine actuator response and stability under varying operational loads.

Utilizing high-speed digital processing and embedded control logic, this module translates input commands—typically from engine governors or process controllers—into accurate actuator control signals. Whether used in load control, start/stop sequencing, or engine positioning, the 5501-432 ensures optimized response and precise output, reducing overshoot, oscillation, and wear on mechanical components.

Engineered for rugged performance and field adaptability, the module excels in power generation, marine propulsion, oil and gas, and industrial drive systems where reliable actuator control is paramount.

Product Specifications

| Specification | Details |

|---|---|

| Model | 5501-432 |

| Product Type | Actuator Control Module |

| Power Supply | 18–32 VDC (Nominal 24 VDC) |

| Power Consumption | < 20 W |

| Input Channels | 4 Analog Inputs / 4 Digital Inputs |

| Output Channels | 2 Actuator Control Outputs (PWM / Analog) |

| Output Current Capability | Up to 3 A per channel |

| Signal Types Supported | 4–20 mA, 0–5 V, PWM, Pulse |

| Feedback Loop Support | Yes (closed-loop control) |

| Control Modes | Proportional, Integral, Derivative (PID) |

| Microcontroller | Embedded 32-bit RISC processor |

| Communication Interfaces | RS-232, RS-485, optional CAN |

| Environmental Protection | Conformal-coated PCB, shock and vibration-resistant |

| Operating Temperature | -40°C to +70°C |

| Storage Temperature | -55°C to +85°C |

| Mounting Style | Panel or DIN-rail mountable |

| Dimensions (W × H × D) | 260.35 × 247.65 × 25.4 mm |

| Weight | 0.93 kg |

| Certifications | CE, UL, CSA, RoHS Compliant |

| Configuration Software | Woodward ToolKit or GAP™ Editor |

Product Applications

The Woodward 5501-432 is widely implemented in actuator-driven systems where accuracy, stability, and reliability are essential. Key industries and applications include:

-

Power Generation

Provides precise actuator control for gas and steam turbines used in grid-tied and isolated systems. -

Industrial Engines and Compressors

Ensures reliable throttle or valve control on engines used for compressors, blowers, and mechanical drives. -

Marine Propulsion Systems

Delivers fine engine positioning and propulsion control in variable-pitch or fixed-pitch setups. -

Oil & Gas Sector

Manages control valves and actuators in drilling rigs, refining equipment, and pump stations. -

Combined Heat & Power (CHP)

Controls flow and fuel systems in high-efficiency co-generation installations. -

Test and Simulation Environments

Utilized in engine test benches and simulators where repeatability and response time are critical.

Product Advantages

The 5501-432 Actuator Control Module provides numerous operational and engineering benefits:

-

High-Speed Control Logic

Fast processing enables real-time actuator adjustments and high-resolution control under dynamic conditions. -

Versatile Output Options

Supports a wide range of signal outputs, including PWM and analog, compatible with most actuator types. -

Closed-Loop Precision

Integrated feedback loop capabilities maintain desired actuator position or velocity with minimal error. -

Flexible Input/Output

Multiple analog and digital I/O channels offer adaptability for complex systems. -

Built for Harsh Environments

Industrial-grade design with wide temperature range and conformal coating ensures long-term reliability. -

Software Customization

Easily configurable using Woodward’s ToolKit or GAP™ logic editor for specific application needs. -

Compact and Mountable

DIN or panel mounting options make it suitable for both retrofit and OEM installations.

FAQ (Frequently Asked Questions)

-

What is the purpose of the 5501-432 module?

-

It controls actuators in engine and turbine systems, translating digital signals into precise actuator movements.

-

-

What types of outputs does it support?

-

It provides PWM, analog voltage, and current loop outputs compatible with most actuators.

-

-

Can it be used in a closed-loop control system?

-

Yes, it supports closed-loop feedback for highly accurate positioning and control.

-

-

Is the module configurable via software?

-

Yes, configuration is done using Woodward ToolKit or GAP™ software.

-

-

What kind of communication protocols are supported?

-

RS-232, RS-485, and optionally CAN.

-

-

How many input channels does it have?

-

4 analog inputs and 4 digital inputs are included for signal sensing or logic control.

-

-

Is it hot-swappable?

-

No, the module must be powered down before replacement or servicing.

-

-

What types of actuators can it control?

-

It is compatible with most electric actuators that accept analog or PWM signals.

-

-

Can this module be used in marine applications?

-

Yes, it is suitable for marine engine and propulsion actuator control.

-

-

What kind of mounting options are available?

-

It supports DIN-rail and direct panel mounting for easy integration.

Related Models (Same Series or Functional Alternatives)

| Model | Type | Outputs | Features | Applications |

|---|---|---|---|---|

| 5501-430 | Actuator Control Module | 2 PWM | Basic version for general actuator control | Diesel engines, gensets |

| 5501-431 | Actuator Interface Module | Analog/PWM | Feedback loop with redundancy support | Steam turbines |

| 5501-433 | Digital Control Module | Analog + CAN | Enhanced I/O with CANbus for distributed control | Marine propulsion systems |

| 5501-214 | Governor Control Module | Actuator + Sensor | Combines governor logic and actuator control | Industrial engines |

| 505XT | Steam Turbine Controller | Multi-output | Turbine-specific logic with actuator interface | Power generation |

| ProAct IV | Integrated Actuator System | Built-in Actuator | Combines actuator and controller in one | Retrofit systems |

Popular Models from the Same Brand (Woodward)

| Model | Type | Function | Primary Application |

|---|---|---|---|

| 2301D | Digital Load Sharing Module | Speed/load sharing for gensets | Power plants, parallel gensets |

| 505E | Steam Turbine Controller | Valve, extraction, and speed control | Medium-size steam turbines |

| 723PLUS | Engine Management System | Full control for large reciprocating engines | Oil & gas, power generation |

| LS-5 | Load Share Controller | Load transfer and synchronizing | Utility switching, grid sync |

| SPM-D2 | Synchronizer Module | Phase/voltage matching for gen parallel | Backup generator systems |

| EasYgen-3500XT | Genset Control System | All-in-one genset control with touchscreen | Commercial and industrial generator sets |

Excellent PLC

Excellent PLC