| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

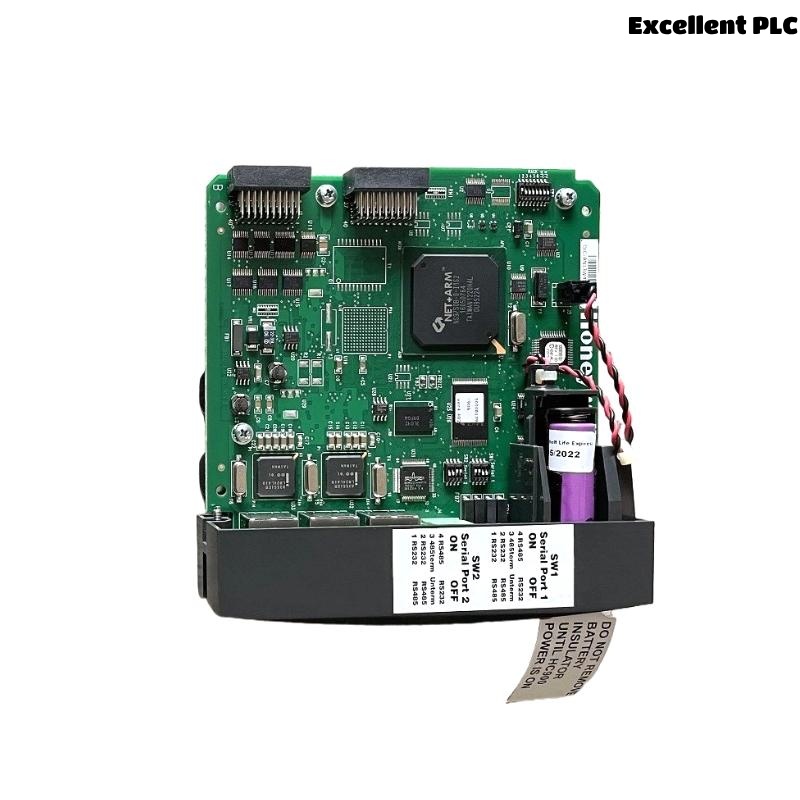

The Honeywell 900C72-0144-00 is the HC900 C70 Controller CPU, the highest-performance processor in Honeywell’s acclaimed HC900 Hybrid Control System family. It is specifically designed for complex and large-scale control applications requiring rapid execution, high I/O capacity, integrated logic, and secure communication.

The HC900 C70 excels in process automation, thermal control, and safety environments, with up to 8000 I/O point capacity, multiple communication ports, and native support for advanced networking protocols like Modbus TCP/IP. It also supports redundant CPU and power configurations, making it ideal for mission-critical systems demanding 24/7 uptime.

Combined with Honeywell’s intuitive Hybrid Control Designer (HCD) software and seamless integration into SCADA and DCS systems, the C70 CPU offers a powerful and scalable platform for automation engineers.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | 900C72-0144-00 |

| Product Name | HC900 C70 Controller CPU |

| System Type | Hybrid Process Automation Controller |

| CPU Performance Class | C70 (High Performance) |

| User Memory | 2 MB non-volatile memory |

| RAM (Battery-backed) | 128 KB |

| Max I/O Capacity | Up to 8000 I/O points |

| Scan Time | < 25 ms for 1000 I/O points |

| Control Loops | Supports up to 200 PID loops |

| Communication Ports | 2 × Ethernet 10/100Base-T, 1 × RS-485 (Modbus RTU) |

| Modbus Support | Modbus TCP/IP (Master/Slave), Modbus RTU |

| Programming Software | Hybrid Control Designer (HCD) |

| Redundancy | Supports CPU and Power Redundancy |

| Mounting Type | DIN rail or panel-mounted |

| Power Supply Input | 24 VDC (supplied via separate power module) |

| Operating Temperature | 0°C to +60°C (32°F to +140°F) |

| Storage Temperature | –40°C to +85°C (–40°F to +185°F) |

| Humidity Range | 5% to 95% RH (non-condensing) |

| Enclosure | Open-style unit (requires panel or cabinet installation) |

| Dimensions (H × W × D) | 137 × 38.1 × 151.7 mm |

| Weight | 0.454 kg |

| Certifications | CE, UL, CSA, FM, RoHS, Class I Div 2 (on select configurations) |

Applications

The HC900 C70 CPU is purpose-built for demanding industrial automation scenarios, combining fast execution, flexibility, and a rugged form factor. Key applications include:

-

Thermal Processing Plants

Controls multi-zone ovens, kilns, and autoclaves with fast PID execution and ramp/soak capabilities. -

Batch Process Industries

Widely used in chemical, pharmaceutical, and food & beverage for batch sequencing, recipe control, and regulatory compliance. -

Water & Wastewater Systems

Ideal for large-scale infrastructure with distributed I/O, remote diagnostics, and advanced alarm handling. -

Petrochemical and Refinery Systems

Handles combustion control, reaction processes, interlocks, and real-time monitoring. -

Power Generation

Suitable for gas turbines, boiler control, and balance-of-plant systems. -

Environmental Chambers and Climatic Test Equipment

Provides high-speed, multi-loop control for lab-grade precision and industrial durability.

Product Advantages

-

High Processing Capacity

Designed for large-scale automation, supporting up to 8000 I/O points and 200+ PID loops. -

Redundancy-Ready Design

Built-in support for CPU and power redundancy ensures uninterrupted system operation. -

Advanced Networking

Dual Ethernet ports and RS-485 allow seamless integration with plant SCADA, HMIs, or third-party PLCs. -

Flexible Deployment

Supports modular expansion with I/O and specialty modules, making it suitable for centralized or distributed topologies. -

Robust Operating Range

Operates in temperatures from 0°C to +60°C and storage down to –40°C, suitable for harsh industrial environments. -

Simplified Configuration

Uses Honeywell’s Hybrid Control Designer (HCD), which simplifies setup, PID tuning, and I/O configuration. -

Compliance with Industry Standards

Certified for global use, including hazardous areas with Class I Division 2 ratings. -

Unified Control and Safety

Can integrate process control and safety applications within a single architecture, reducing cost and footprint.

Frequently Asked Questions (FAQ)

-

Q: What is the primary function of the HC900 C70 Controller CPU?

A: It acts as the central processing unit for Honeywell’s HC900 control system, managing complex process logic, I/O, and communications. -

Q: How many I/O points can the C70 support?

A: It supports up to 8000 I/O points through modular expansion. -

Q: What types of communication protocols are supported?

A: It supports Modbus TCP/IP (master/slave) and Modbus RTU over RS-485. -

Q: Does it support redundancy?

A: Yes, it offers support for redundant CPUs and redundant power modules to maximize uptime. -

Q: Which software is used for programming the HC900 C70?

A: Honeywell’s Hybrid Control Designer (HCD) is used for system configuration and programming. -

Q: Can the HC900 C70 be used for thermal process applications?

A: Absolutely. It is widely used for batch ovens, kilns, heat treaters, and other temperature-critical processes. -

Q: Is the unit DIN rail mountable?

A: Yes, it supports both DIN rail and panel mounting configurations. -

Q: What’s the memory capacity of the C70 CPU?

A: It includes 2 MB of non-volatile memory and 128 KB of battery-backed RAM. -

Q: Can it be integrated with third-party SCADA systems?

A: Yes, via Modbus protocols, it can integrate with most SCADA and HMI platforms. -

Q: Is this controller certified for hazardous locations?

A: Yes, select configurations are certified for Class I Div 2 and comply with FM, UL, CE, and CSA standards.

Related Models from the HC900 Series

| Model Number | Description | Max I/O Capacity | Communication | CPU Class |

|---|---|---|---|---|

| 900C50-0244-00 | HC900 C30 CPU (Compact) | Up to 1500 | Ethernet, Modbus RTU | C30 |

| 900C51-0243-00 | HC900 C40 Mid-range CPU | Up to 2000 | Ethernet, RS-485 | C40 |

| 900C52-0243-00 | HC900 C50 CPU (Advanced) | Up to 4000 | Ethernet, Modbus TCP/IP | C50 |

| 900C70-0143-00 | HC900 C70 CPU (Legacy version) | Up to 8000 | Ethernet, Serial | C70 |

| 900CP1-0300-00 | HC900 Compact CPU | Up to 512 | Limited Modbus | Compact |

| 900R50-0001 | Redundant CPU Kit for HC900 | N/A | Redundancy Synchronization | Redundancy |

Popular Honeywell Industrial Automation Products

| Model Number | Product Type | Application | Key Feature |

|---|---|---|---|

| UDC3500 | Universal Digital Controller | Process and temperature control | High-accuracy PID |

| STG700 SmartLine | Pressure Transmitter | Oil & gas, water treatment | HART / Wireless protocols |

| Experion PKS C300 | Distributed Control System (DCS) | Enterprise automation | Scalable I/O + Fault Tolerance |

| ControlEdge PLC | Industrial Controller | Discrete & batch process control | OPC UA / IIoT Ready |

| HC900-C50 | Mid-performance hybrid controller | Furnace, oven, and water systems | Up to 4000 I/O |

| SLN700 | Level Transmitter | Liquid measurement | SmartLine communication |

Excellent PLC

Excellent PLC