| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

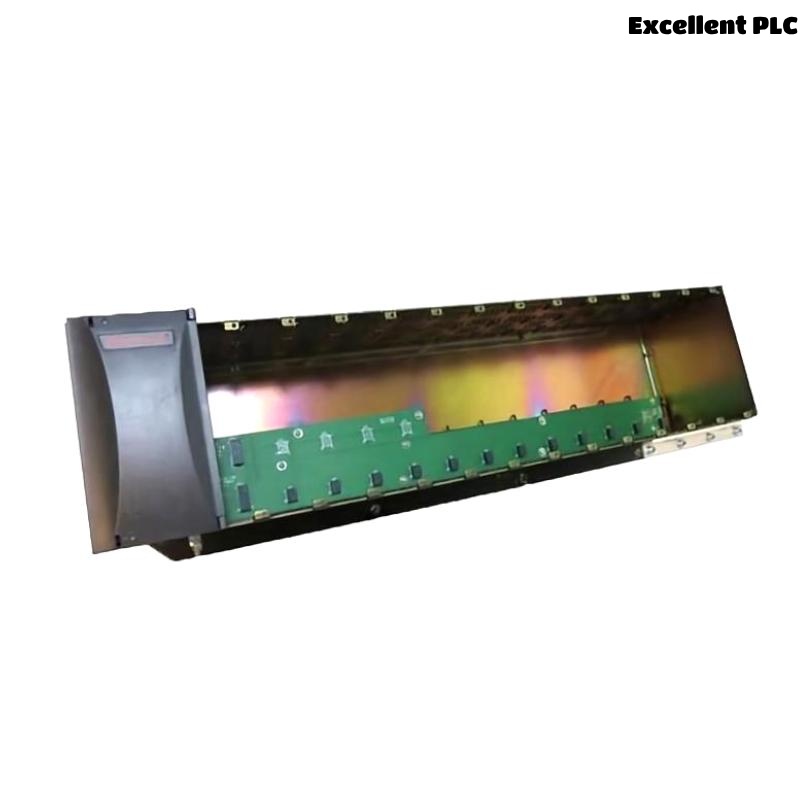

The Honeywell 900RR0-0300 is a critical component of the ControlEdge™ HC900 Process and Safety System, serving as a redundant CPM (Control Processing Module) rack. It is specifically designed to support redundant control strategies for high-availability automation processes. By enabling dual CPM configurations, this rack allows for seamless transition between primary and backup processors, ensuring uninterrupted control in mission-critical applications.

Designed for medium to large-scale process control systems, the 900RR0-0300 provides a modular and scalable architecture that supports hot-swap capabilities, optimized I/O flexibility, and industry-standard communication protocols. It is ideal for use in highly regulated and safety-conscious industries such as pharmaceuticals, petrochemicals, power generation, and food and beverage.

Product Specifications

| Parameter | Description |

|---|---|

| Model | 900RR0-0300 |

| Manufacturer | Honeywell |

| System | ControlEdge™ HC900 |

| Function | Redundant CPM rack for dual CPU architecture |

| Slot Configuration | Supports 2 Control Processing Modules (Primary & Backup) |

| Redundancy Type | CPM Hot-standby redundancy |

| Power Supply Requirement | 24V DC nominal (with redundant PSU support) |

| Backplane Type | HC900 Backplane for CPU/Power modules |

| Material | Industrial-grade aluminum alloy chassis |

| Mounting Style | Panel or rack-mounted (DIN rail optional) |

| Operating Temperature | 0°C to 60°C (32°F to 140°F) |

| Storage Temperature | -40°C to 85°C |

| Relative Humidity | 5% to 95% non-condensing |

| Certifications | CE, UL, CSA, ATEX, IECEx |

| Firmware Upgradeable | Yes |

| Dimensions (H × W × D) | 137 x 261.6 x 151.7 mm |

| Weight | 1.751 kg |

| Enclosure Protection | IP20 (when installed inside certified enclosure) |

Product Applications

The Honeywell 900RR0-0300 is essential for systems where process reliability, safety, and minimal downtime are paramount. Key application areas include:

-

Pharmaceutical Manufacturing

For batch control, environmental monitoring, and GAMP-compliant automation. -

Chemical and Petrochemical Plants

Applied in reactor control, pressure monitoring, and high-integrity safety loops. -

Power Generation Facilities

Used in turbine control, boiler management, and auxiliary equipment redundancy. -

Food and Beverage Production

Controls pasteurization, packaging, CIP (clean-in-place), and redundancy for safety-critical processes. -

Water and Wastewater Treatment

Provides redundancy for pump control, filtration sequencing, and telemetry systems. -

Oil & Gas Processing

Ensures continuous operation of compressors, separators, and flare control systems.

Product Advantages

-

Seamless Redundancy

Supports dual CPMs (Primary and Backup) in hot-standby mode, minimizing control disruption. -

Fault Tolerance

In case of primary CPM failure, the system automatically switches to the standby module. -

Industrial Durability

Built from robust materials and tested under extreme environmental conditions. -

Flexible Integration

Compatible with other HC900 components and standard industrial protocols (Modbus TCP, Ethernet/IP, OPC). -

Easy Maintenance

Hot-swappable modules allow maintenance without shutting down the entire system. -

Reliable Communication

Maintains uninterrupted communication with I/O modules, HMIs, and plant networks during switchover. -

Modular Design

Supports scalable expansion of control systems, reducing initial setup cost and allowing future upgrades.

Frequently Asked Questions (FAQ)

1. What is the primary function of the 900RR0-0300 rack?

It is used to house redundant CPMs in a ControlEdge HC900 system, ensuring high availability and continuous control.

2. Can the rack support hot-swapping of the CPM modules?

Yes, the rack and supported modules are hot-swappable, enabling maintenance without system shutdown.

3. Is it compatible with standard HC900 I/O racks?

Yes, it integrates seamlessly with standard HC900 I/O modules and backplanes.

4. What power supply does the rack require?

It operates on 24V DC and can accommodate redundant power inputs for reliability.

5. What is the benefit of CPM redundancy?

It provides system continuity by automatically transferring control to a backup CPM if the primary fails.

6. What kind of environments can the rack operate in?

It is suitable for industrial environments with wide temperature and humidity ranges.

7. Does it support communication redundancy as well?

While the rack supports CPM redundancy, network redundancy depends on the CPM configuration and network setup.

8. What safety certifications does this model carry?

The unit is certified under CE, UL, CSA, ATEX, and IECEx standards.

9. Can this rack be used in safety instrumented systems (SIS)?

Yes, it can be part of safety-certified architectures when paired with appropriate HC900 modules.

10. How is the switchover between primary and backup CPMs handled?

Switchover is automatic, fast, and seamless—designed to prevent control loss or interruption.

Related Models from the Same Series

| Model | Description | Function | Compatibility |

|---|---|---|---|

| 900R08-0001 | HC900 8-slot I/O Rack | I/O Expansion Rack | HC900 CPU, I/O Modules |

| 900P01-0101 | HC900 Power Supply Module | Power Supply | Compatible with all racks |

| 900C32-0101 | HC900 32-Channel Digital Input Module | Digital Input | HC900 I/O Base |

| 900C52-0001 | HC900 High-Speed Counter Module | Pulse/Counter Input | ControlEdge HC900 |

| 900CP1-0010 | HC900 Control Processor (non-redundant) | CPM | ControlEdge HC900 |

| 900HEU-0001 | HC900 Engineering Unit | Configuration Interface | All HC900 Platforms |

Popular Honeywell Automation Modules

| Model | Description | Function | Platform |

|---|---|---|---|

| CC-PAIN01 | C300 Analog Input Module | Analog Input | Experion C300 |

| CC-PAOH01 | C300 Analog Output Module | Analog Output | Experion C300 |

| CC-PDOB01 | C300 Digital Output Module | Digital Output | Experion C300 |

| CC-TDIL01 | C300 Digital Input Module | Digital Input | Experion C300 |

| 51454469-275 | 32-Point Digital Output Module | Digital Output | Series A |

| 900H32-0302 | 32-Channel Digital Output Module for HC900 | Digital Output | ControlEdge HC900 |

Excellent PLC

Excellent PLC