| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Overview

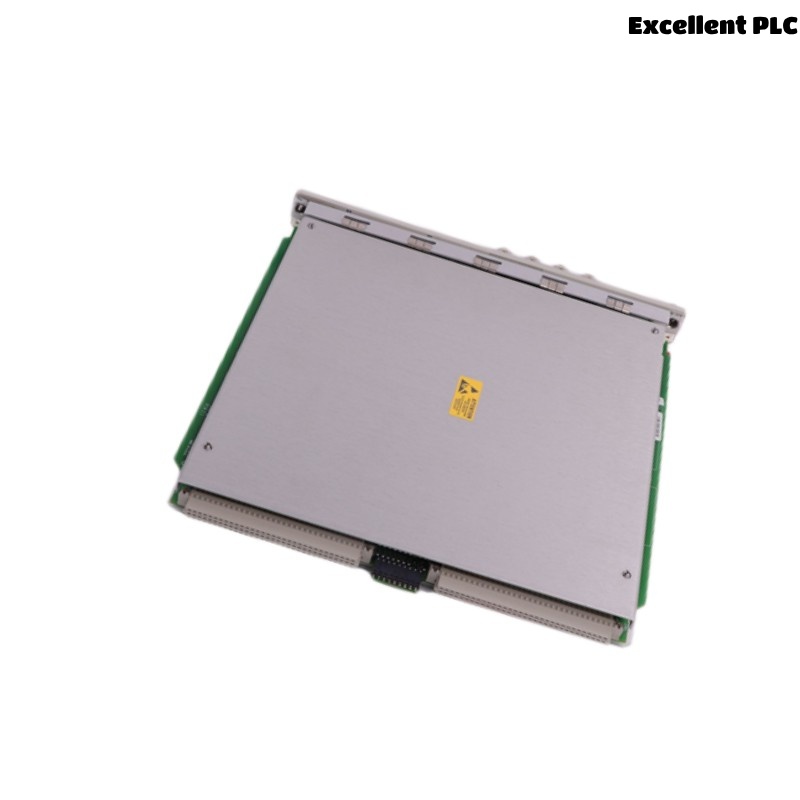

The Bently Nevada 3500/40M-01-00 176449-01 Proximitor Monitor is a high-precision monitoring module designed to measure shaft vibration, axial position, and keyphasor (phase reference) signals in rotating machinery. As part of the world-renowned Bently Nevada 3500 Machinery Protection System, this module provides real-time condition monitoring, ensuring early fault detection and proactive machinery protection.

The 3500/40M Proximitor Monitor offers unmatched measurement accuracy for critical assets such as turbines, compressors, generators, and pumps. Its seamless integration with Bently Nevada proximity probes makes it a vital component for predictive maintenance and safeguarding industrial equipment.

Key Features

-

High-precision monitoring of shaft radial vibration, axial position, and keyphasor signals

-

Compatible with Bently Nevada 3300 XL, 7200 Series proximity probes and sensors

-

Two independent monitoring channels per module

-

Real-time measurements to support machinery protection and diagnostics

-

Configurable alarms for alert and danger thresholds

-

Complies with API 670 standards for rotating equipment protection

-

LED indicators for quick status verification and fault diagnostics

-

Integrated signal processing and filtering for accurate readings

-

Industrial-grade design for continuous operation in harsh environments

-

Full compatibility with Bently Nevada 3500 System architecture

Technical Specifications

| Specification | Details |

|---|---|

| Product Name | Bently Nevada 3500/40M Proximitor Monitor |

| Model Number | 3500/40M-01-00 |

| Part Number | 176449-01 |

| Channels | 2 independent channels per module |

| Measurement Types | Shaft radial vibration, axial position, keyphasor signals |

| Compatible Probes | Bently Nevada 3300 XL and 7200 Series Proximity Probes |

| Radial Vibration Measurement Range | 0 to 200 μm (8 mils) peak-to-peak |

| Axial Position Measurement Range | ±2 mm (±80 mils) |

| Frequency Response | 0 to 20 kHz typical |

| Alarm Outputs | Configurable ALERT and DANGER alarms via system relays |

| Signal Processing | Integrated signal conditioning and filtering |

| Communication Interface | Direct connection via 3500 rack backplane |

| Diagnostic Indicators | LED indicators for OK, ALERT, DANGER, BYPASS status |

| Power Supply | Supplied through 3500 System rack |

| Operating Temperature Range | -30°C to +65°C |

| Storage Temperature Range | -40°C to +85°C |

| Certifications | CE, CSA, ATEX, IECEx (region-dependent) |

| Dimensions | 241.3 x 24.4 x 241.8 mm |

| Weight | 0.91 kg |

Industry Applications

The 3500/40M-01-00 176449-01 Proximitor Monitor is essential in industries where continuous monitoring and protection of rotating machinery is critical:

-

Oil & Gas: Vibration and position monitoring of compressors, turbines, and pumps

-

Power Generation: Shaft vibration monitoring in steam and gas turbines

-

Petrochemical Industry: Condition monitoring for critical rotating equipment

-

Metals & Mining: Machinery protection for crushers, mills, and heavy equipment

-

Marine & Offshore: Shaft movement and vibration monitoring for propulsion systems

-

Industrial Manufacturing: Predictive maintenance for motors and rotating assets

Product Advantages

-

Accurate Real-Time Measurements: Detects shaft vibration, position, and keyphasor signals with high precision

-

Supports Predictive Maintenance: Enables early fault detection, reducing unplanned downtime and equipment damage

-

Versatile Monitoring Functions: One module for radial vibration, axial position, and phase reference measurements

-

Seamless Integration: Fully compatible with the Bently Nevada 3500 System architecture

-

Compliance with API 670 Standards: Meets stringent global requirements for machinery protection

-

Rugged Industrial Design: Engineered for reliable performance in extreme environments

-

Customizable Alarms: User-defined ALERT and DANGER thresholds for tailored protection

-

Efficient Diagnostics: LED indicators provide immediate visual status feedback

-

Enhanced Machine Safety: Continuous monitoring minimizes risks of catastrophic failures

Frequently Asked Questions (FAQ)

1. What is the main purpose of the 3500/40M-01-00 176449-01 Proximitor Monitor?

It continuously monitors shaft vibration, axial position, and keyphasor signals to protect rotating machinery from damage.

2. Which proximity probes are supported?

It is compatible with Bently Nevada 3300 XL and 7200 Series proximity probes and sensors.

3. How many channels are available on the module?

The module offers two independent monitoring channels.

4. Can it generate alarm outputs?

Yes, it provides configurable ALERT and DANGER alarms via relay modules within the 3500 system.

5. Does the module support keyphasor (phase reference) measurements?

Yes, it delivers accurate phase reference signals crucial for vibration analysis and diagnostics.

6. Is the 3500/40M API 670 compliant?

Yes, the monitor supports API 670 standards for rotating machinery protection.

7. What is the operating temperature range?

The module operates reliably between -30°C and +65°C.

8. Are diagnostics included?

Yes, LED indicators provide real-time status for OK, ALERT, DANGER, and BYPASS conditions.

9. How is the module powered?

It receives power through the Bently Nevada 3500 rack backplane.

10. In which industries is this monitor commonly applied?

It is used in oil & gas, power generation, petrochemical, marine, mining, and industrial manufacturing sectors.

Related Models from the Same Series

| Model | Description |

|---|---|

| 3500/40M-02-00 176449-02 | 4-Channel Proximitor Monitor for expanded applications |

| 3500/42M-01-00 176449-03 | Vibration Monitor for radial and axial measurements |

| 3500/25 149369-01 | Keyphasor Module for precise phase reference signals |

| 3500/33-02-00 149992-02 | 16-Channel Relay Module for alarm outputs |

| 3500/15 127610-01 | Power Supply Module for the Bently Nevada 3500 system |

| 3500/22M-01-01-00 | Transient Data Interface for advanced system diagnostics |

Popular Bently Nevada Products Across Related Categories

| Model | Description |

|---|---|

| 330104-00-05-10-02-00 | 3300 XL 8 mm Proximity Probe for shaft monitoring |

| 330130-040-00-00 | 3300 XL Extension Cable for sensor installations |

| 330180-91-05 | 3300 XL Proximitor Sensor for vibration measurements |

| 3500/05 140734-01 | System Rack for Bently Nevada 3500 Series Modules |

| 3500/92-01-01-00 | Communication Gateway for external data integration |

| 3500/53 133388-01 | Overspeed Detection Module for rotating equipment |

Excellent PLC

Excellent PLC