| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

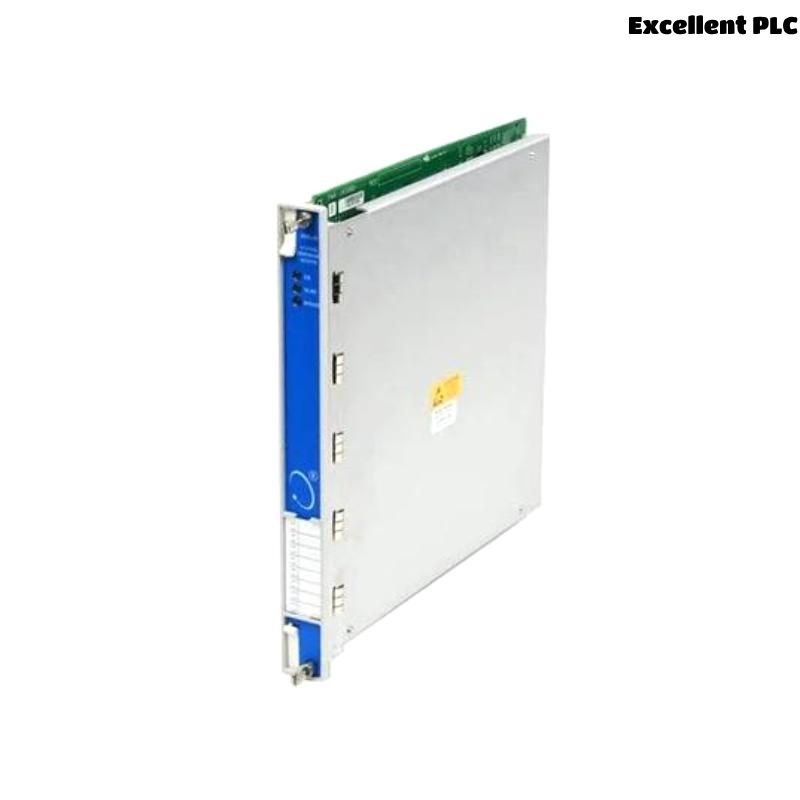

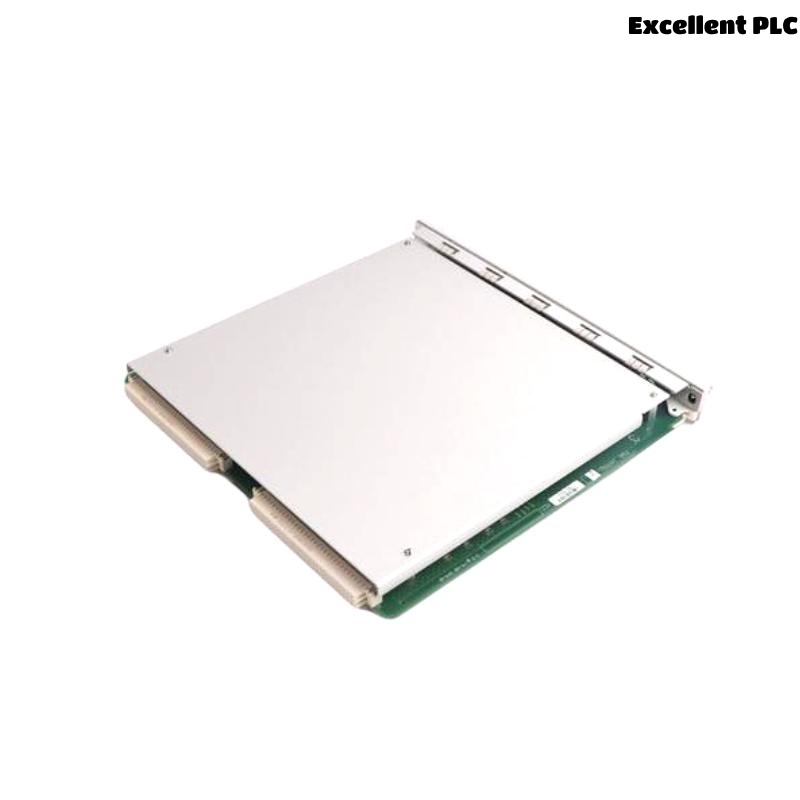

The Bently Nevada 3500/32 125720-02 + 125712-01 is a 4-Channel Relay Module that forms an essential component of the Bently Nevada 3500 Machinery Protection System. Specifically designed for industrial applications requiring high reliability and fault-tolerant logic, this module offers four independently configurable relay outputs to trigger alarms, shutdowns, or other critical responses.

Each relay on the module can be driven by alarm conditions detected by any monitoring module in the 3500 rack. This makes it ideal for use in machinery protection and condition monitoring solutions, such as for steam turbines, gas turbines, compressors, pumps, and other rotating or reciprocating equipment.

With its robust build quality, programmable logic control, and integration with the 3500 rack’s system-wide diagnostics and communications, the 3500/32 module delivers precise, fast, and reliable relay control in some of the world’s most demanding environments.

Product Specifications

| Specification | Details |

|---|---|

| Model Number | 3500/32 |

| Part Numbers | 125720-02 (Relay Module), 125712-01 (I/O Module) |

| Number of Channels | 4 Independent Channels |

| Relay Type | Electromechanical, SPDT (Single Pole Double Throw) |

| Relay Rating | 5 A at 24 VDC or 250 VAC (resistive load) |

| Relay Configuration | Normally Energized or De-energized (software-configurable) |

| Relay Operating Life | ≥ 100,000 operations at rated load |

| Contact Isolation | 1500 VDC minimum from system ground |

| Power Consumption | < 3.0 Watts |

| Control Signal Source | From alarms generated by any 3500 series monitoring module |

| Voting Logic Support | Yes – 1-out-of-2 or 2-out-of-3 logic supported |

| Mounting | Installed in designated slot in the 3500 rack |

| Hot Swappable | Yes |

| Diagnostic LEDs | Yes – Relay status and health indicators |

| Dimensions (W x H x D) | 241 x 24.4 x 242 mm |

| Weight | 0.7 kg |

| Operating Temperature Range | -30°C to +65°C |

| Storage Temperature Range | -40°C to +85°C |

| Humidity | 0–95% RH, non-condensing |

| Certifications | CE, CSA, ATEX, IECEx |

| Compatibility | Fully compatible with Bently Nevada 3500 racks |

Product Applications

The 3500/32 Relay Module is tailored for mission-critical industrial environments where real-time condition monitoring and automated system responses are necessary. Key application areas include:

-

Steam and Gas Turbines – For overspeed protection, bearing vibration alarms, and shutdown logic

-

Compressors – For high vibration trip signals and surge detection response

-

Pumps and Motors – For dry run protection, high temperature shutoff, and overload prevention

-

Generators – For insulation monitoring, critical fault detection

-

Petrochemical Facilities – For system interlock logic and process condition alerts

-

Power Plants – For turbine control logic, rotor stress alarms, and emergency shutdown

This module ensures that alarm-triggered responses are executed accurately and quickly, reducing the risk of catastrophic machinery failure or plant downtime.

Product Advantages

-

High Flexibility

Each of the four relays can be independently configured for various alarm or shutdown actions, allowing highly customizable protection schemes. -

Fast and Reliable Response

Relay response is immediate, ensuring protection systems engage in real time when conditions demand it. -

Logic-Based Control

Supports logical voting strategies (e.g., 2-out-of-3) for added safety and reduced false trip scenarios. -

Seamless Integration

Easily integrates with the rest of the 3500 series monitoring modules, making it ideal for complex protection architectures. -

Field-Replaceable Design

The module can be replaced while the rack remains powered, minimizing operational disruption. -

Proven Durability

Engineered for extreme industrial conditions with full adherence to international certification standards.

Frequently Asked Questions (FAQ)

1. What’s the difference between 125712-01 and 125720-02?

125720-02 is the relay module itself, while 125712-01 is the associated I/O module that interfaces the relays with the external wiring.

2. Are the relays mechanical or solid-state?

The relays are electromechanical SPDT types, offering high current switching capability.

3. Can each relay be assigned to different alarm types?

Yes, relays can be individually mapped to specific alarms from any monitor in the 3500 rack.

4. What’s the load capacity of each relay?

Each relay can handle up to 5 A at 24 VDC or 250 VAC resistive loads.

5. Does the module support hot-swapping?

Yes, it can be inserted or removed from the rack without powering down the system.

6. Can I configure logic like 2-out-of-3 voting with this module?

Yes, the module supports voting logic, ideal for redundant safety systems.

7. How is diagnostic information accessed?

The module status is shown via onboard LEDs and through the 3500/22M System Display or via software.

8. What industries use the 3500/32 module?

It is widely used in power generation, petrochemical, oil and gas, and manufacturing sectors.

9. Can this module be used as part of a SIL-rated system?

While not SIL-rated on its own, it can be incorporated into SIL-compliant architectures with proper design.

10. How long do the relays typically last?

Under rated load, relay life expectancy exceeds 100,000 operations.

Related Models from the Same Series

| Model | Description |

|---|---|

| 3500/33 | 16-Channel Relay Module |

| 3500/40M | Proximitor Monitor Module |

| 3500/42M | Proximitor/Seismic Monitor Module |

| 3500/15 | Universal Power Supply Module |

| 3500/22M | Transient Data Interface Module (TDI) |

| 3500/20 | Rack Interface Module (RIM) |

Popular Models from Bently Nevada

| Model | Description |

|---|---|

| 330104-00-05-10-02-00 | 3300 XL Series Proximity Probe |

| 330180-91-00 | High-Temperature Velocity Transducer |

| 330130-040-00-00 | Extension Cable for Proximity Probe |

| 3500/42M | Seismic and Vibration Monitoring Module |

| 3500/22M | TDI with Ethernet/RS232 Communications |

| 330500-02-00 | Accelerometer Sensor for Seismic Vibration Measurement |

Excellent PLC

Excellent PLC