| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

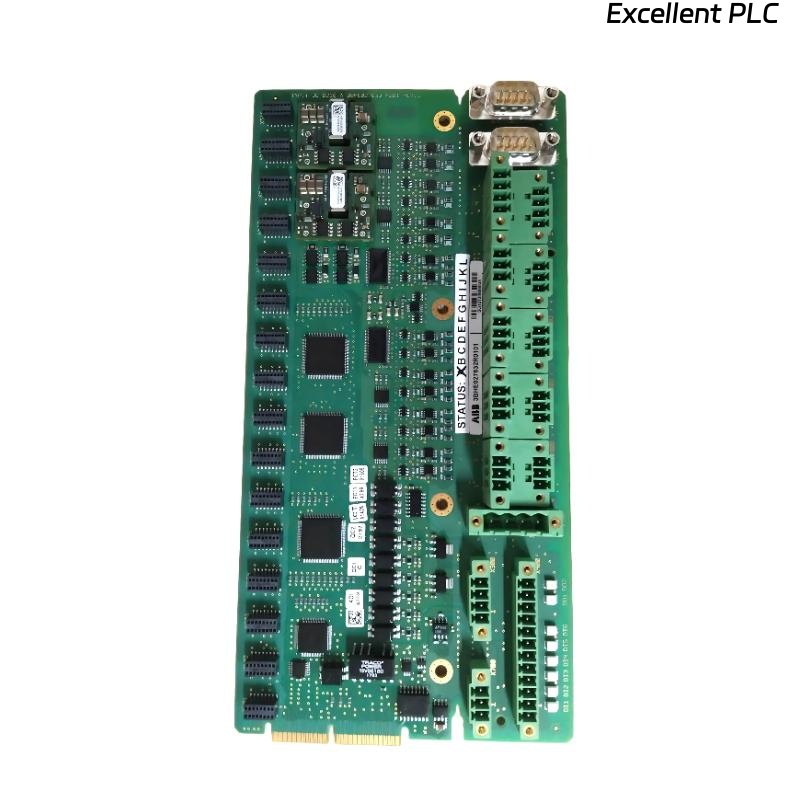

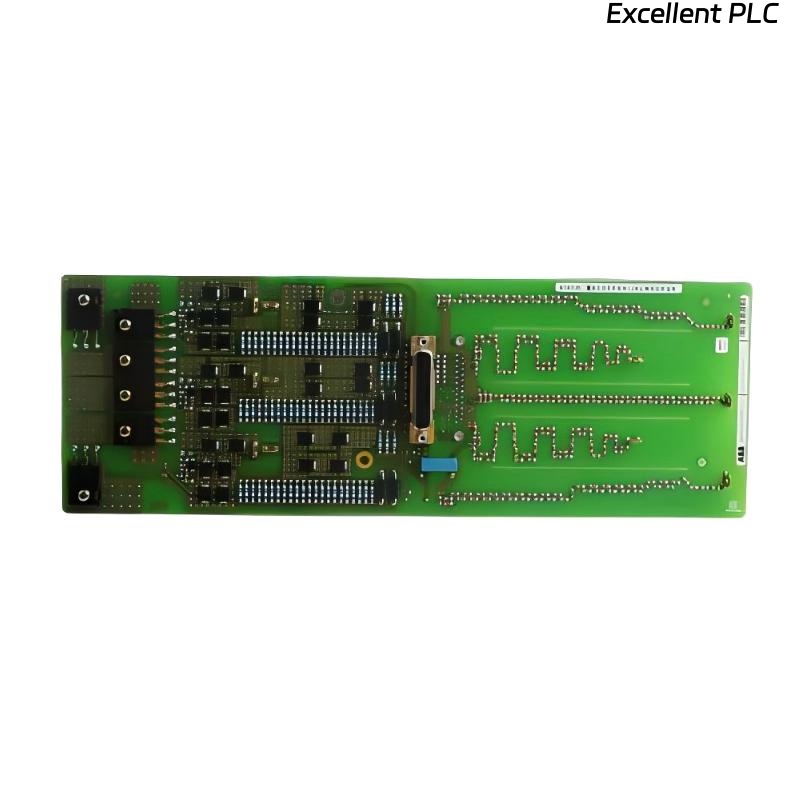

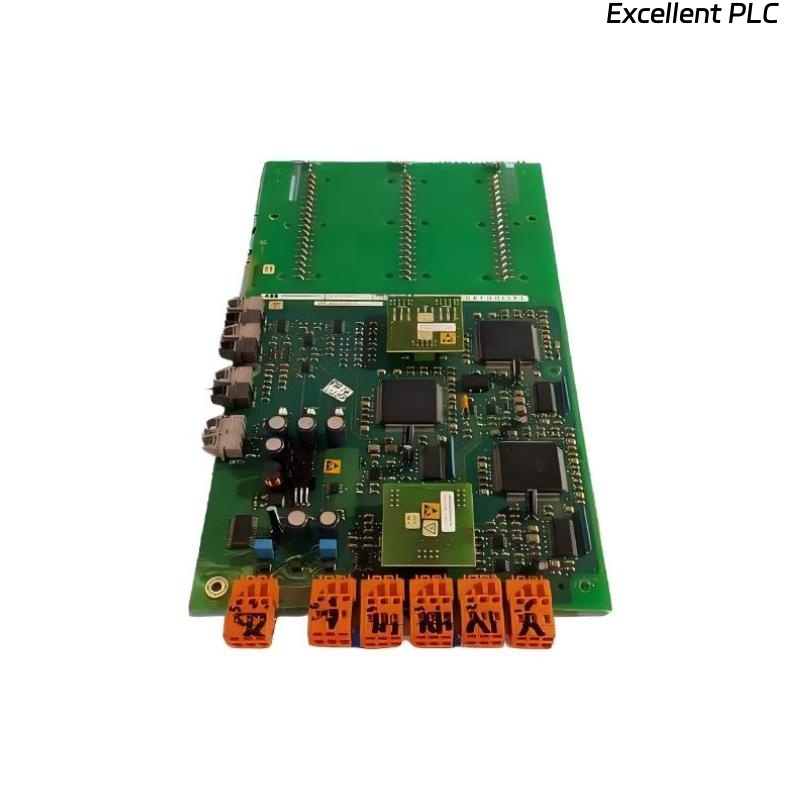

The ABB FMBA-01 is a communication adapter module designed specifically to enable Modbus RTU serial communication for ABB’s variable frequency drives (VFDs) and other industrial devices. The FMBA-01 module allows ABB drives to seamlessly integrate into automation networks that use the Modbus RTU protocol, one of the most widely adopted serial communication standards in industrial automation.

This adapter serves as a vital bridge between ABB’s intelligent drives and centralized controllers such as PLCs or SCADA systems, enabling real-time data exchange for monitoring, diagnostics, and command control. Its design prioritizes reliability, minimal configuration effort, and robust electrical performance, making it an ideal solution for both new installations and retrofitting existing systems.

Product Specifications

| Parameter | Details |

|---|---|

| Product Name | ABB FMBA-01 Modbus RTU Adapter Module |

| Communication Protocol | Modbus RTU (RS-485, 2-wire half-duplex) |

| Supported Baud Rates | 300 to 19200 bps (configurable) |

| Mounting Type | Slot-in (Drive plug-in adapter) |

| Application Compatibility | ABB ACS series drives (e.g., ACS355, ACS550) |

| Power Supply | Powered by the host drive |

| Indicators | Status LED for module activity and diagnostics |

| Isolation | Galvanic isolation for RS-485 interface |

| Operating Temperature | -10°C to +60°C |

| Storage Temperature | -40°C to +70°C |

| Humidity | 5% to 95% non-condensing |

| Certifications | CE, UL, cUL, RoHS |

| Dimensions (H x W x D) | 63 x 74.4 x 26.3 mm |

| Weight | 0.12 kg |

| Enclosure Rating | IP20 (when installed in drive) |

Applications

The FMBA-01 module is widely used in a variety of industrial and commercial settings where Modbus RTU protocol is prevalent. Key applications include:

-

HVAC Systems: Integrates VFDs into building automation networks for energy-efficient HVAC control.

-

Water & Wastewater: Links drives controlling pumps and blowers to SCADA systems.

-

Manufacturing Lines: Interfaces production equipment with central PLCs for real-time feedback and control.

-

Material Handling: Used in conveyor systems and automated storage solutions.

-

Renewable Energy Plants: Provides monitoring and diagnostics of motor-driven systems.

-

Food & Beverage Industry: Ensures precise speed control and communication in processing equipment.

Key Advantages

-

Seamless Integration: Provides straightforward plug-in compatibility with ABB drives.

-

Standardized Communication: Supports the widely accepted Modbus RTU protocol.

-

Ease of Configuration: Parameter settings via the drive panel or PC tools like DriveWindow Light.

-

Galvanic Isolation: Enhances protection and reduces communication errors caused by ground loops.

-

Compact Form Factor: Occupies minimal space within the drive module.

-

Robust Diagnostics: Built-in LED indicators aid in troubleshooting communication issues.

-

Reliable Performance: Proven stability in harsh industrial environments.

-

Future-Proofing: Facilitates integration with legacy and modern automation systems alike.

Frequently Asked Questions (FAQ)

-

Q: Which ABB drives are compatible with the FMBA-01 module?

A: It supports various ABB ACS series drives such as ACS150, ACS355, ACS550, and others. -

Q: Does FMBA-01 support full-duplex communication?

A: No, it supports half-duplex RS-485 communication, which is standard for Modbus RTU. -

Q: Can I configure the module using DriveWindow Light?

A: Yes, configuration and diagnostics can be performed using ABB’s DriveWindow Light software. -

Q: Is external power required for the FMBA-01 module?

A: No, it draws power directly from the host ABB drive. -

Q: Does the FMBA-01 support Modbus ASCII?

A: No, it only supports the Modbus RTU protocol. -

Q: Is the module hot-swappable?

A: No, it should only be inserted or removed when the drive is powered off. -

Q: How do I monitor the status of communication?

A: The built-in status LED indicates module activity and error states. -

Q: Can it be used in outdoor environments?

A: It should be housed inside an enclosure or control cabinet rated for outdoor use, as the module itself is rated IP20. -

Q: What is the maximum communication distance supported?

A: RS-485 typically supports up to 1200 meters, depending on baud rate and cable type. -

Q: Does it require special drivers or software for integration?

A: No special drivers are required. It uses standard Modbus RTU protocols supported by most PLCs and HMIs.

Related or Similar ABB Modules

| Model | Description | Protocol | Compatibility |

|---|---|---|---|

| FBPA-01 | Profibus DP Adapter Module | Profibus DP | ABB Drives (ACS Series) |

| FENA-01 | Ethernet Adapter Module | EtherNet/IP | ACS355, ACS550 |

| FENA-11 | Dual-Port Ethernet Adapter | EtherNet/IP, Modbus TCP | ACS Series |

| RDIO-01 | Relay and Digital I/O Extension Module | I/O Expansion | ACS355, ACS550 |

| FCAN-01 | CANopen Adapter Module | CANopen | ACS Drives |

| FCBL-01 | Control Panel Extension Module | Control Panel | ACS150, ACS355 |

Popular ABB Automation Modules

| Model | Description | Application | Communication |

|---|---|---|---|

| PM573-ETH | ABB AC500 PLC CPU Module with Ethernet | Industrial Automation Controller | Ethernet |

| CI854AK01 | Communication Interface for Profibus | Freelance/800xA Systems | Profibus DP |

| AI810 | Analog Input Module (8-channel, 0–20mA) | ABB S800 I/O System | Analog Input |

| DO810 | Digital Output Module (16 channels) | ABB S800 I/O | Digital Output |

| CP600 HMI | ABB Control Panel 7″ to 15″ Touchscreen HMIs | Machine Interface | Ethernet, RS-232/485 |

| TU810V1 | Module Termination Unit for S800 I/O modules | System Integration | Module Backplane |

Excellent PLC

Excellent PLC