| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

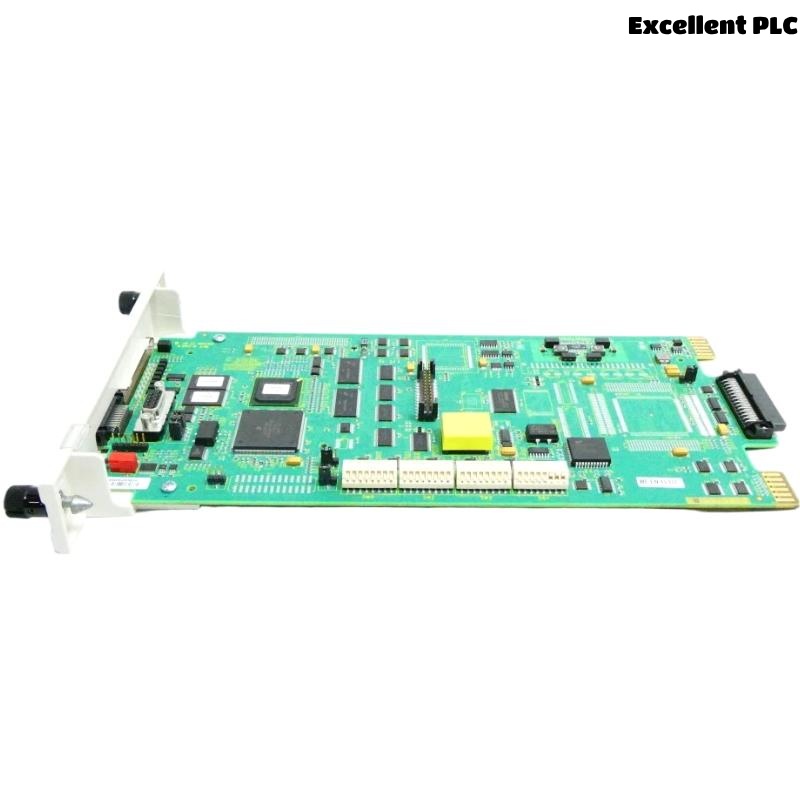

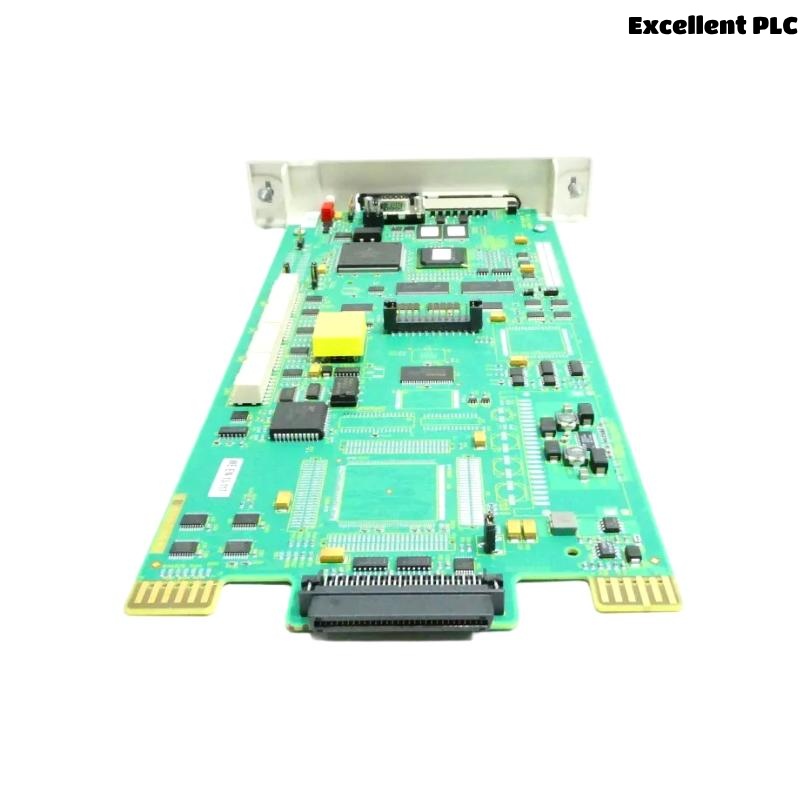

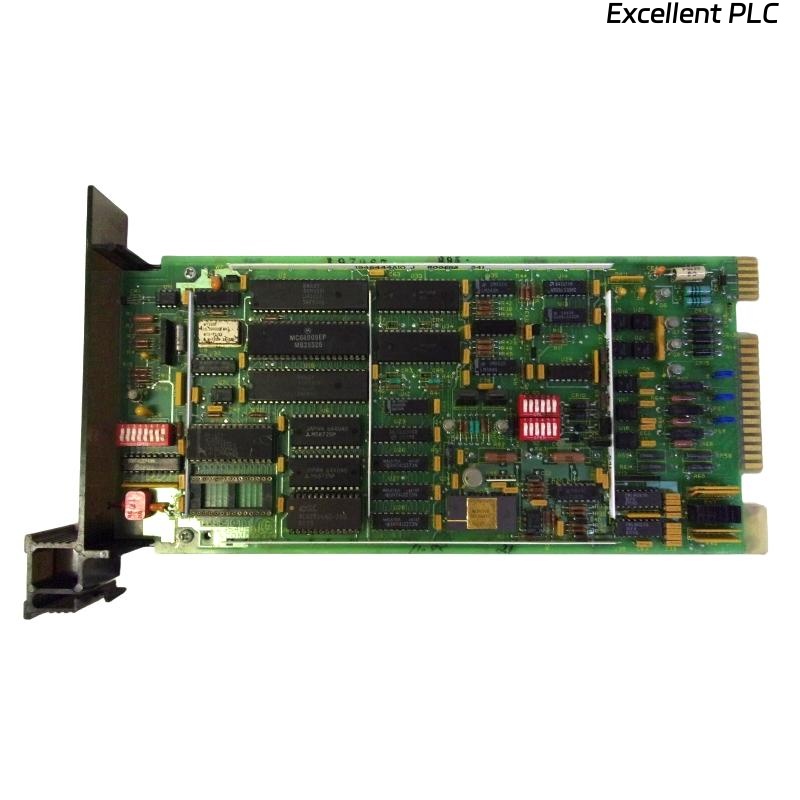

The ABB Bailey SPSEM11 is a dedicated Sequence of Events (SOE) Master Module engineered for precise event monitoring and time stamping within ABB’s INFI 90 and Symphony series Distributed Control Systems (DCS). It functions as the centralized coordinator that gathers time-critical digital input data from SOE slave modules and accurately records events with millisecond resolution.

The SPSEM11 module is vital for diagnosing operational conditions, improving process safety, and analyzing plant behavior during disturbances. Its ability to log and organize the exact sequence of digital input transitions allows for rapid identification of root causes, helping to prevent downtime and improve system responsiveness.

Designed for demanding industrial environments, the SPSEM11 ensures robust communication, accurate time correlation, and system-wide integration with ABB Bailey I/O modules. It is particularly useful in applications requiring strict process accountability and audit trails, such as power generation, oil and gas, and mission-critical infrastructure.

Technical Specifications

| Parameter | Details |

|---|---|

| Product Name | Sequence of Events (SOE) Master Module |

| Model Number | SPSEM11 |

| Manufacturer | ABB (Bailey Controls) |

| System Compatibility | INFI 90, Symphony, Symphony Plus |

| Primary Function | Coordinates digital input events from SOE slave modules |

| Event Time Resolution | 1 ms time stamping |

| SOE Communication | Communicates with multiple SPSES11 slave modules |

| Time Synchronization | Receives or transmits timing pulses for system-wide accuracy |

| Time Sync Sources | Master Clock, GPS, or External Synchronizer (depending on setup) |

| Status Indicators | LEDs for module health, comm activity, and SOE status |

| Diagnostics | Built-in fault detection and reporting |

| Mounting Type | Rack-mounted within Bailey INFI 90 chassis |

| Input/Output Channels | Interfaces digitally with SOE slave modules |

| Redundancy Support | Can be configured in redundant pairs for critical processes |

| Power Supply | 24 VDC via system backplane |

| Operating Temperature | 0°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Humidity Range | 5% to 95% non-condensing |

| Certifications | CE, UL, CSA, RoHS |

| Dimensions (W × H × D) | 76.2 x 355.6 x 254 mm |

| Weight | 0.8 kg |

Product Applications

The SPSEM11 module is deployed in a wide range of process control and safety-critical systems requiring accurate digital event tracking. Key applications include:

-

Power Generation Facilities

Logs breaker operations, relay actions, turbine trips, and fault occurrences with precise timing. -

Oil and Gas Refineries

Records digital transitions from emergency shutdown systems (ESD), fire and gas detectors, and interlocks. -

Substation Automation

Coordinates with SCADA systems for fault analysis and relay operation timing. -

Water and Wastewater Treatment

Monitors pump starts/stops, level alarms, and gate operations in event-driven automation. -

Petrochemical Plants

Captures safety system activations and control logic transitions for forensic troubleshooting. -

Heavy Industry / Metals Processing

Tracks machinery safety interlocks and event responses in real-time for compliance and safety.

Product Advantages

-

Millisecond Precision Time Stamping

Enables highly accurate event analysis for operational and safety-critical diagnostics. -

Centralized SOE Management

Acts as the master module collecting data from multiple SPSES11 slave units. -

System-wide Time Synchronization

Can interface with master clocks or GPS-based sources for consistent timing across the control network. -

Field-Proven Reliability

Trusted in high-availability environments with continuous operation requirements. -

Integrated Diagnostics

Built-in diagnostics facilitate rapid fault identification and isolation. -

Modular Architecture

Easily integrates into ABB Bailey system racks, supporting scalable event logging systems. -

LED Status Indicators

Provide clear, real-time visibility into communication and operational health. -

Redundancy Option

Can be deployed in fault-tolerant redundant configurations for critical systems. -

Simplified Troubleshooting

Provides detailed event sequences to accelerate root cause analysis of alarms or trips.

Frequently Asked Questions (FAQ)

-

What is the primary function of the SPSEM11 module?

It serves as the Sequence of Events master, collecting time-stamped digital transitions from SOE slave modules. -

How many slave modules can SPSEM11 communicate with?

It typically supports multiple SPSES11 slave modules, depending on system configuration and bus architecture. -

What kind of time accuracy does the module provide?

SPSEM11 can log events with 1 millisecond resolution, ensuring high-precision diagnostics. -

Does this module require external synchronization?

Yes. It can synchronize with GPS clocks, master time sources, or external pulse generators depending on setup. -

Can the module operate in a redundant configuration?

Absolutely. It supports primary-backup redundancy to ensure uninterrupted event logging. -

Is the SPSEM11 compatible with Symphony Plus systems?

Yes, it is fully compatible with INFI 90, Symphony, and Symphony Plus architectures. -

What types of events does the module capture?

It captures discrete digital transitions such as open/close, on/off, or fault occurrences from field devices. -

Does it have built-in diagnostics?

Yes. The module includes onboard diagnostics to detect communication or hardware faults. -

How is the module connected within the system?

It is rack-mounted in a Bailey control chassis and communicates via the system backplane and SOE bus. -

Are the events logged stored in non-volatile memory?

Event records are managed by the controller system. The SPSEM11 provides real-time timestamped data, which is stored based on system software configuration.

Related ABB Bailey Models

| Model | Description | System Compatibility | Dimensions (mm) | Weight |

|---|---|---|---|---|

| SPSES11 | SOE Slave Module | INFI 90, Symphony | 160 × 130 × 45 | 0.7 kg |

| SPNIS21 | Network Interface Module | INFI 90, Symphony | 160 × 130 × 45 | 0.75 kg |

| SPDSI14 | 16-Channel Digital Input Module | INFI 90, Symphony | 160 × 130 × 45 | 0.65 kg |

| SPDSO14 | 16-Channel Digital Output Module | INFI 90, Symphony | 160 × 130 × 45 | 0.65 kg |

| SPASI23 | Analog Input Module | INFI 90, Symphony | 160 × 130 × 45 | 0.65 kg |

| SPCIS22 | Control Input Module | INFI 90, Symphony | 160 × 130 × 45 | 0.7 kg |

Popular ABB Models Across Product Lines

| Model | Description | Category | Dimensions (mm) | Weight |

|---|---|---|---|---|

| PM866K02 | Redundant CPU Module for 800xA | Controller Module | 127 × 186 × 110 | 1.2 kg |

| REF615 | Feeder Protection Relay | Protection Relay | 230 × 175 × 150 | 2.1 kg |

| SD812V1 | 24 VDC Power Supply | Power Supply Module | 55 × 130 × 125 | 0.8 kg |

| CP635 | 10” Industrial Touch Panel | HMI | 260 × 185 × 55 | 1.1 kg |

| ACS880-01 | Universal AC Drive | Variable Frequency Drive | 297 × 420 × 237 | 9.5 kg |

| TU830V1 | I/O Terminal Unit | Terminal Unit | 120 × 80 × 50 | 0.4 kg |

Excellent PLC

Excellent PLC