| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Overview

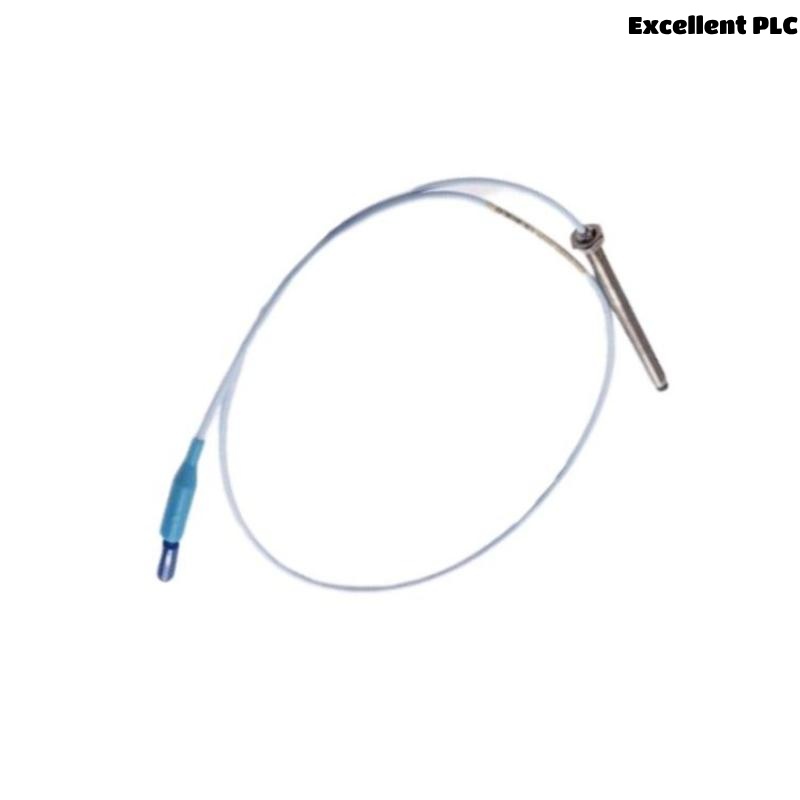

The Bently Nevada 330103-00-05-15-02-CN 3300 XL 8 mm Proximity Probe is part of the 3300 XL series, a premier line of non-contacting sensors developed by Bently Nevada for continuous machinery condition monitoring. This model is engineered to provide accurate shaft position and vibration measurements for critical rotating machinery and equipment.

Designed with a robust 8 mm probe tip, a 5-meter integral cable, and a 5/8-18 UNF mounting thread, this particular model features a customized connector configuration for the China region (indicated by the “-CN” suffix), making it ideal for region-specific installations or integration with localized monitoring systems.

It is especially well-suited for harsh industrial environments, offering a rugged, sealed construction that resists oil, moisture, and contaminants while delivering high signal fidelity over extended cable lengths.

Key Features

-

8 mm probe diameter for stable and reliable displacement measurements

-

5-meter integrated cable with low-noise triaxial shielding

-

5/8-18 UNF mounting thread for secure mechanical fit

-

Special regional configuration (-CN), typically used in Chinese industrial setups

-

High temperature and vibration tolerance

-

Designed for use with 3300 XL Proximitor sensors and extension cables

-

IP68 sealed design ensures durability in contaminated environments

-

Compliant with API 670, CE, and regional regulatory standards

-

Factory pre-calibrated and field-proven across global industries

-

Backward-compatible with legacy Bently Nevada systems

Technical Specifications

| Item | Specification |

|---|---|

| Product Model | 330103-00-05-15-02-CN |

| Series | 3300 XL 8 mm |

| Probe Tip Diameter | 8 mm |

| Mounting Thread Size | 5/8-18 UNF-2A |

| Sensing Range | 2 mm (80 mils) |

| Linear Range | 0.25 mm to 2.0 mm (10 to 80 mils) |

| Connector Orientation | Custom connector (China region specification) |

| Cable Length | 5 meters (integral) |

| Cable Type | Triaxial low-noise cable |

| Probe Body Material | AISI 304 Stainless Steel |

| Operating Temperature | -35°C to +177°C (-31°F to +351°F) |

| Storage Temperature | -51°C to +177°C (-60°F to +351°F) |

| Environmental Protection | IP68 (when installed correctly) |

| Vibration Limit | 50 g peak, 10 Hz to 2 kHz |

| Shock Limit | 5000 g, 1 msec half-sine pulse |

| Insulation Resistance | >10⁹ ohms at 500 VDC |

| System Accuracy (Typical) | ±0.07 mm (±2.8 mils) |

| Compliance Standards | API 670, CE, RoHS, China GB standards |

| Dimensions | Total Length : 1.5 meters |

| Weight | 0.484 kg |

Industry Applications

The 330103-00-05-15-02-CN model is deployed in a wide range of critical monitoring scenarios:

-

Petrochemical Facilities – Compressors, pumps, and expanders

-

Thermal & Nuclear Power Plants – Steam and gas turbine vibration analysis

-

Oil Exploration Platforms – Drill motors and mud pumps

-

Steel and Rolling Mills – Motor and gearbox vibration detection

-

Marine Applications – Shaft alignment and vibration diagnostics

-

Cement Industry – Kiln and raw mill drive systems

-

Water Treatment & Pumping Stations – Large pump shaft monitoring

-

Chinese OEM Systems – Tailored for integration in GB-standard setups

Product Advantages

-

Localized Compatibility: CN suffix denotes regional compliance and connector types preferred in China

-

Stainless Steel Build: Withstands industrial corrosives and high-vibration applications

-

Straightforward Integration: Fully interoperable with existing 3300 XL systems

-

Optimized Cable Design: Noise-resistant triaxial cable ensures clean signals over long distances

-

Sealed for Harsh Conditions: Performs reliably in oil, water, and dust environments

-

No Maintenance Required: Non-contact design eliminates wear-and-tear points

-

High Sensitivity: Capable of detecting minute shaft displacements

-

Global Certifications: Conforms to API 670, CE, and regional standards

-

Wide Thermal Range: Supports extreme high and low temperatures

-

Application-Proven: Trusted by Chinese and global industries for over two decades

Frequently Asked Questions (FAQ)

-

What is the significance of the “-CN” in the part number?

It indicates a custom connector version tailored for the China region, typically used in systems adhering to Chinese GB standards. -

Is this probe compatible with standard 3300 XL proximitor sensors?

Yes, it’s fully compatible with all Bently Nevada 3300 XL proximitor sensors. -

Can this be used in hazardous or outdoor environments?

Yes, with its IP68 sealing, it can withstand moisture, dust, and chemical exposure. -

What is the benefit of the 5/8-18 UNF thread?

It provides a more robust mechanical engagement, often required in heavy-duty machinery or deeper probe insertion points. -

Is the cable shielded for EMI resistance?

Yes, it uses triaxial shielding to minimize electromagnetic interference. -

Does it require calibration?

No, it’s factory-calibrated, but periodic system checks are advised. -

What connector type is used in the CN version?

Typically a region-specific straight coaxial or MIL-style connector adapted to China market preferences. -

How long is the expected operating life?

With proper installation, these probes typically operate reliably for 7–10 years. -

Can this probe be used in retrofitting older machines?

Yes, it’s backward compatible with most Bently Nevada systems and works well in upgrades. -

What is the optimal distance between probe and shaft during setup?

Recommended initial gap is around 1 mm (40 mils), adjustable based on monitoring setup.

Related Models

| Model Number | Description |

|---|---|

| 330103-00-05-15-01-00 | 5 m cable, 5/8-18 thread, standard straight connector |

| 330103-00-05-15-12-00 | 5 m cable, 5/8-18 thread, 90° connector |

| 330103-00-06-15-02-CN | 6 m cable, 5/8-18 thread, 90° connector, China version |

| 330103-00-08-15-01-00 | 8 m cable, 5/8-18 thread, straight connector |

| 330104-00-10-10-02 | 10 m XL extension cable, straight BNC |

| 330180-91-05 | Proximitor sensor compatible with 8 mm probe, 5 m cable |

Popular Bently Nevada Models

| Model Number | Description |

|---|---|

| 3500/22M-01-01-00 | Transient Data Interface Module |

| 330130-045-01-00 | XL Standard Extension Cable, 4.5 m |

| 330104-00-05-10-02 | XL Extension Cable, 5 m |

| 1900/65A-00-01-01 | General-Purpose Vibration Monitor Module |

| 3500/42M-01-00 | Dual Vibration Monitor for Proximitor Systems |

| 330500-02-00 | Thrust and Vibration Monitoring Module |

Excellent PLC

Excellent PLC