| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

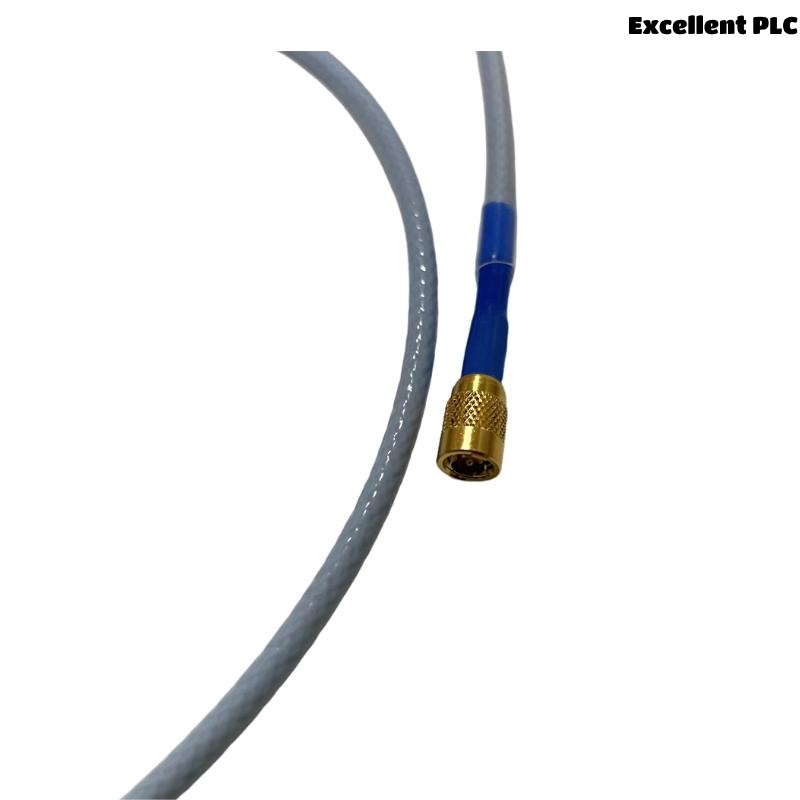

The Bently Nevada 330103-01-04-05-02-CN 8 mm Proximity Probe is part of the 3300 XL Series, a range of precision proximity probes designed for highly accurate vibration and displacement monitoring in industrial applications. This model uses eddy current technology to monitor the relative position between the probe and a target object, making it suitable for critical rotating equipment where accurate measurements are vital to prevent machinery failures.

With an 8 mm shaft diameter, the 330103-01-04-05-02-CN probe is commonly used in applications requiring continuous, real-time condition monitoring of machinery such as turbines, motors, compressors, and generators. By continuously measuring displacement and vibration, the probe helps operators detect misalignment, imbalance, and other issues before they lead to equipment failure, ultimately reducing maintenance costs and downtime.

Product Parameters

| Parameter | Specification |

|---|---|

| Model | 330103-01-04-05-02-CN |

| Type | 8 mm Proximity Probe |

| Total Length | 0.5 meter |

| Weight | 0.161 kg |

| Shaft Diameter | 8 mm |

| Operating Temperature | -40°C to +120°C |

| Range | 1-25 mil (0.0254-0.635 mm) |

| Mounting Type | Direct Mount |

| Measurement Principle | Eddy Current |

| Cable Length | 0.5 meter |

| Accuracy | ± 0.001 inch (± 0.0254 mm) |

Product Applications

The 330103-01-04-05-02-CN proximity probe is ideal for use in a variety of industries, including:

-

Power Generation: The probe is used for continuous monitoring of turbines, compressors, and generators in power plants, ensuring early detection of misalignment, imbalance, and other faults.

-

Oil & Gas Industry: Offshore rigs, refineries, and gas pipelines rely on the probe to monitor rotating equipment such as pumps, motors, and compressors, preventing costly downtime and ensuring efficient operation.

-

Aerospace: In aerospace applications, the probe is used to monitor turbines and engines, where precision and reliability are critical to ensuring safe operation.

-

Manufacturing: The probe is also used to monitor factory equipment, including conveyor belts, robotic arms, and other critical machinery, helping prevent breakdowns in production lines.

-

Marine: Ships and offshore platforms use the probe to monitor engines and rotating systems, improving safety and operational efficiency in harsh environments.

-

Transportation: In the transportation sector, the probe is employed for the real-time monitoring of engines and machinery in vehicles such as trains, airplanes, and industrial transport systems.

Product Advantages

-

High Precision: With an accuracy of ± 0.001 inch (± 0.0254 mm), this probe provides highly accurate measurements, crucial for the reliable monitoring of machinery.

-

Durability: Designed for use in harsh environments, the probe operates effectively in a temperature range of -40°C to +120°C, making it suitable for a wide range of industrial settings.

-

Non-contact Measurement: Using eddy current technology, the probe performs non-contact measurements, eliminating wear and extending the lifespan of the probe.

-

Real-time Feedback: The probe provides continuous data, allowing operators to detect mechanical issues early, preventing costly unplanned maintenance and repair work.

-

Versatile: With its 8 mm shaft diameter, the probe can be used in a variety of rotating equipment, from large turbines to smaller motors, in multiple industries.

-

Cost-Effective: The long lifespan and minimal maintenance requirements of the probe reduce overall operational costs, making it a cost-effective solution for machinery monitoring.

-

Predictive Maintenance: The probe helps support predictive maintenance programs by detecting early signs of faults, such as vibration imbalances, and alerting operators to potential issues before they escalate.

-

Easy Integration: The probe integrates seamlessly with Bently Nevada’s 3300 XL vibration monitoring systems, offering a unified solution for machinery condition monitoring.

-

Low Maintenance: The probe’s non-contact design reduces wear and tear, leading to fewer maintenance interventions and lower long-term operating costs.

-

Long Operational Life: The robust design and the use of high-quality materials ensure a long service life, even in demanding industrial environments.

Frequently Asked Questions (FAQ)

Q1: What is the technology used in the 330103-01-04-05-02-CN probe?

A1: The probe uses eddy current technology for non-contact displacement and vibration measurements, ensuring high accuracy and reliability.

Q2: What is the accuracy of this probe?

A2: The 330103-01-04-05-02-CN probe has an accuracy of ± 0.001 inch (± 0.0254 mm), which ensures precise measurements for machinery monitoring.

Q3: What is the total length of the 330103-01-04-05-02-CN probe?

A3: The total length of the probe is 0.5 meters, making it ideal for use in a wide range of applications.

Q4: How much does the 330103-01-04-05-02-CN probe weigh?

A4: The probe weighs 0.161 kg, making it easy to install and handle during maintenance.

Q5: What is the operating temperature range for this probe?

A5: The probe operates in temperatures ranging from -40°C to +120°C, allowing it to be used in various industrial environments.

Q6: How does the probe support predictive maintenance?

A6: The probe helps identify early signs of mechanical issues by continuously monitoring displacement and vibration, allowing for proactive maintenance before problems escalate.

Q7: In which industries can the 330103-01-04-05-02-CN probe be used?

A7: This probe is used in power generation, oil and gas, aerospace, manufacturing, marine, and transportation industries to monitor rotating machinery.

Q8: How does the non-contact measurement benefit the probe?

A8: Non-contact measurement reduces wear on both the probe and the machinery, extending the lifespan of the probe and minimizing the need for maintenance.

Q9: Can the 330103-01-04-05-02-CN probe be used with other monitoring systems?

A9: While designed for use with the 3300 XL vibration monitoring system, the probe can be integrated with other compatible systems for comprehensive machinery condition monitoring.

Q10: How does the probe help detect mechanical problems early?

A10: The probe detects changes in vibration and displacement, which can indicate problems such as misalignment, imbalance, or excessive wear, allowing for early intervention.

Recommended Related Models (Same Series or Related)

| Model | Description | Range | Accuracy | Mounting |

|---|---|---|---|---|

| 330103-01-04-05-02-01 | Extended range 8 mm proximity probe | 1-50 mil (0.0254-1.27 mm) | ± 0.001 inch (± 0.0254 mm) | Direct Mount |

| 330103-01-04-05-02-02 | High temperature 8 mm proximity probe | 1-25 mil (0.0254-0.635 mm) | ± 0.001 inch (± 0.0254 mm) | Direct Mount |

| 330103-01-04-05-02-03 | 8 mm proximity probe with extended cable | 1-25 mil (0.0254-0.635 mm) | ± 0.001 inch (± 0.0254 mm) | Direct Mount |

| 330103-01-04-05-02-04 | Hazardous area 8 mm proximity probe | 1-25 mil (0.0254-0.635 mm) | ± 0.001 inch (± 0.0254 mm) | Direct Mount |

| 330103-01-04-05-02-05 | 8 mm proximity probe with custom length | 1-25 mil (0.0254-0.635 mm) | ± 0.001 inch (± 0.0254 mm) | Direct Mount |

| 330103-01-04-05-02-06 | 8 mm proximity probe for aerospace applications | 1-25 mil (0.0254-0.635 mm) | ± 0.001 inch (± 0.0254 mm) | Direct Mount |

Recommended Popular Models from Bently Nevada

| Model Number | Parameters | Application | Advantages |

|---|---|---|---|

| 330103-00-10-10-12-CN | 24V, 10A, 3-wire | Vibration Monitoring | High accuracy, reliable performance |

| 330103-00-10-50-02-00 | 24V, 15A, 2-wire | Industrial Control Systems | Cost-effective, flexible integration |

| 330103-00-10-10-12-01 | 24V, 12A, 3-wire | Process Control | Durable, high precision |

| 330103-00-10-50-02-01 | 24V, 18A, 2-wire | Motor Control Systems | High power output, stable operation |

| 330103-00-10-10-12-02 | 24V, 20A, 3-wire | Power Distribution Systems | Enhanced durability, reliable |

| 330103-00-10-50-02-02 | 24V, 25A, 2-wire | Automation Systems | High efficiency, long-lasting |

Excellent PLC

Excellent PLC