| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Overview

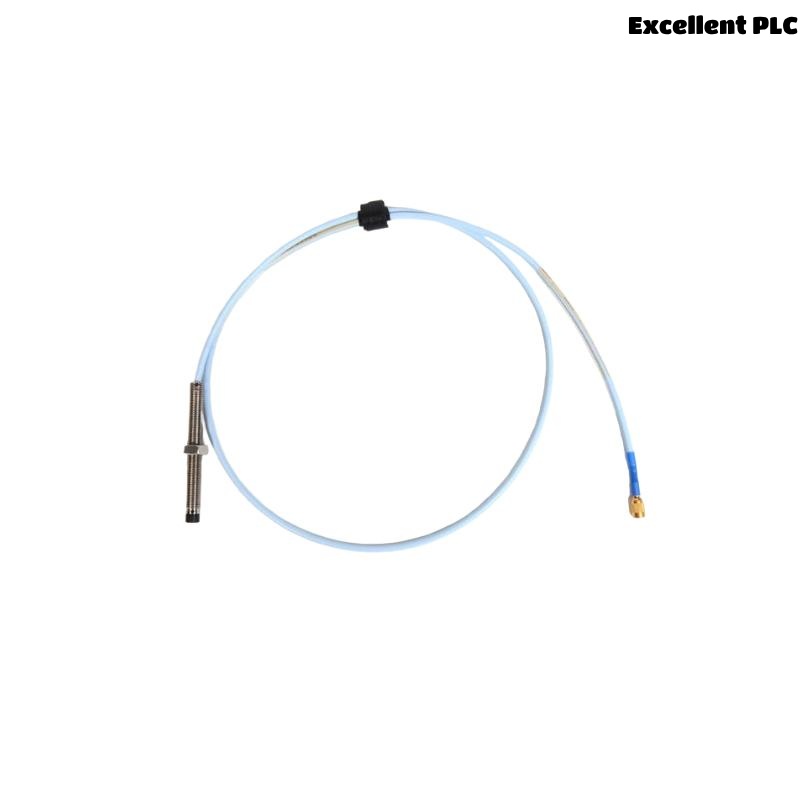

The Bently Nevada 330104-00-08-05-01-05 is a metric proximity probe from the 3300 XL 8 mm series, designed for accurate non-contact vibration and position sensing in industrial rotating machinery. As a vital component in condition monitoring and machinery protection systems, this probe is engineered to deliver high precision and long-term reliability, even in harsh industrial environments.

The 330104-00-08-05-01-05 model features an 8 mm diameter probe tip, a 0.5-meter cable length, and is optimized for use with Bently Nevada’s 3300 XL extension cables and Proximitor® sensors. It is constructed with durable materials and adheres to industry standards like API 670, ensuring compatibility and ruggedness for mission-critical operations.

Technical Specifications

| Parameter | Value |

|---|---|

| Model | 330104-00-08-05-01-05 |

| Series | 3300 XL 8 mm |

| Sensing Principle | Eddy Current |

| Tip Diameter | 8 mm |

| Probe Material | AISI 304 Stainless Steel |

| Thread Type | M10 x 1.0 |

| Thread Length | 25 mm |

| Mounting Length | 45 mm |

| Cable Length | 0.5 meter |

| Connector Type | 90° Angle Male Coaxial Connector |

| Temperature Range | -35°C to +177°C |

| Environmental Protection | IP68 |

| System Compatibility | 3300 XL Extension Cable & Proximitor Sensor |

| Total Length | 0.5 meter |

| Weight | 0.161 kg |

Applications

The 330104-00-08-05-01-05 is tailored for demanding machinery monitoring applications across a variety of sectors, including:

-

Power Generation: Turbines and generators for shaft vibration and radial position monitoring

-

Oil & Gas: Compressors, centrifugal pumps, and turbo expanders

-

Petrochemical Industry: Monitoring gearboxes and rotating reactors

-

Marine & Offshore: Diesel engines and high-speed turbines

-

Steel & Paper Mills: Roll stands and high-speed fans

-

Manufacturing Plants: CNC machines and rotating test beds

Its compact cable length and angled connector make it ideal for installations in space-restricted environments.

Product Advantages

-

High Precision and Stability: Designed with robust linear response over a broad gap range, offering excellent measurement accuracy for displacement and vibration.

-

Superior Environmental Resistance: IP68-rated stainless steel construction allows continuous operation in oil, dust, and high-humidity conditions.

-

Compact Installation Profile: 0.5-meter cable and right-angle connector enable mounting in tight or obstructed machine compartments.

-

Long-Term Durability: Proven field performance over extended operational cycles in high-speed rotating machinery.

-

Compliant with Global Standards: Fully supports ISO and API 670 guidelines for rotating equipment protection.

-

Plug-and-Play Compatibility: Fully interoperable with other 3300 XL system components, ensuring easy installation and calibration-free operation.

Frequently Asked Questions (FAQ)

Q1: What is the primary function of this probe?

A1: It measures the distance between the probe tip and a rotating shaft to monitor vibration or position changes in real time.

Q2: What does the “0.5 meter” cable length mean?

A2: It is the total length of the permanently attached coaxial cable from the probe tip to the angled connector.

Q3: Can this probe be submerged in oil or coolant?

A3: Yes, with its IP68 rating and stainless-steel construction, it is built to withstand immersion in lubricants and fluids.

Q4: What sensor should I use with this probe?

A4: It is designed to be used with Bently Nevada 3300 XL Proximitor® sensors for optimal performance.

Q5: Is the probe suitable for high-temperature environments?

A5: Yes, it is rated to operate in environments ranging from -35°C up to +177°C.

Q6: How do I verify correct installation depth?

A6: Use a calibrated mechanical spacer tool or a dial indicator to ensure the specified probe-to-target gap.

Q7: Will the probe work if mounted near a magnetic field?

A7: Magnetic fields should be avoided, as they can interfere with eddy current measurements.

Q8: What is the benefit of the 90-degree connector?

A8: It simplifies installation in confined spaces and provides strain relief for cable routing.

Q9: Does the probe require recalibration?

A9: No, once installed with compatible hardware, the system is factory calibrated and does not need field calibration.

Q10: What is the typical lifespan of this probe?

A10: When used within specified limits, the probe typically lasts for years without performance degradation.

Recommended Related Models (Same Series or Type)

| Model | Description | Dimensions | Weight |

|---|---|---|---|

| 330104-00-07-10-12-00 | 8 mm probe, 1.0 m cable, straight | M10 thread, 71 mm ML | 0.323 kg |

| 330104-00-08-90-02-05 | 8 mm probe, 8.0 m cable, 90° connector | M10 thread, 90° angle | 0.310 kg |

| 330104-00-10-10-02-00 | 8 mm probe, 10.0 m cable, straight | M10 thread, 80 mm ML | 0.325 kg |

| 330104-00-05-10-12-00 | 8 mm probe, 5.0 m cable, straight | M10 thread, 60 mm ML | 0.310 kg |

| 330104-00-06-10-12-00 | 8 mm probe, 6.0 m cable, straight | M10 thread, 65 mm ML | 0.312 kg |

| 330104-00-12-10-02-00 | 8 mm probe, 12.0 m cable, straight | M10 thread, 85 mm ML | 0.330 kg |

Recommended Popular Bently Nevada Models

| Model | Description | Weight |

|---|---|---|

| 330103-00-12-10-12-00 | 8 mm proximity probe, 1.2 m cable, with extended temperature and dual connector | 0.300 kg |

| 330103-00-12-15-01-05 | 8 mm probe, 1.5 m cable, armored, reverse thread, for tight mount applications | 0.340 kg |

| 330103-00-06-50-02-05 | 8 mm proximity probe, 5.0 m cable, ruggedized with metallic armor sheath | 0.400 kg |

| 330103-00-08-10-01-00 | 8 mm standard probe, 1.0 m cable, metric thread, general-purpose use | 0.290 kg |

| 330103-00-10-15-02-05 | Extended-range probe, 1.5 m cable, heavy-duty, high EMI resistance | 0.360 kg |

| 330103-00-15-10-01-05 | Long cable version, 3.0 m, stainless steel armored, hazardous area approved | 0.420 kg |

Excellent PLC

Excellent PLC