| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Overview

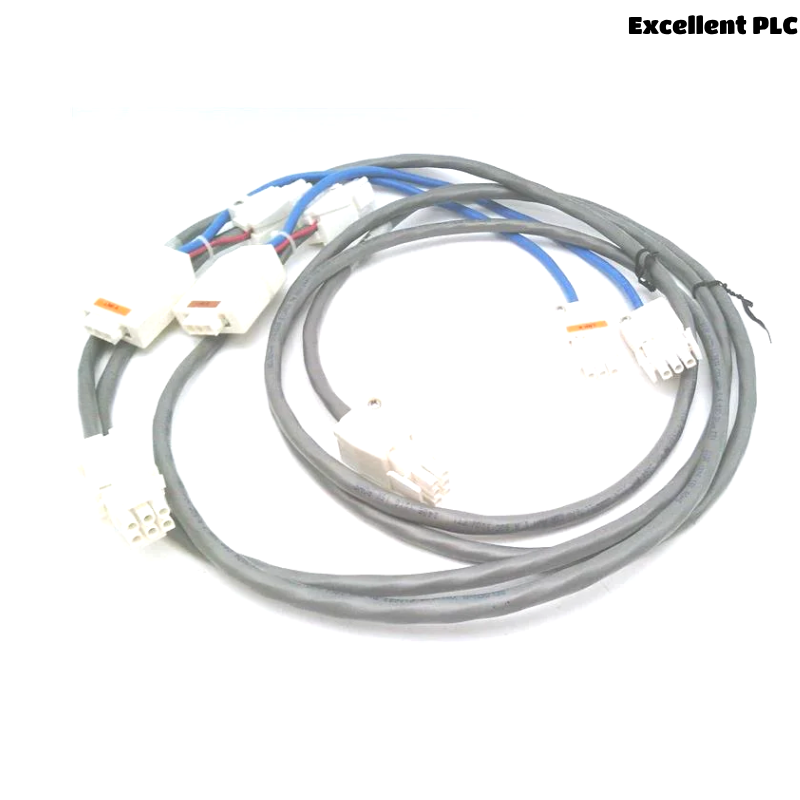

The Honeywell 51204126-002 is a premium-grade industrial sensor/control module designed for mission-critical applications requiring high precision and reliability. As part of Honeywell’s renowned automation solutions portfolio, this component delivers exceptional performance in harsh operating environments across multiple industries.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | 51204126-002 |

| Cable length | 2 m |

| Weight | 0.45 kg |

| Operating Voltage | 18-32V DC |

| Current Consumption | ≤85mA @ 24V DC |

| Output Signal | 4-20mA analog, RS-485 digital |

| Measurement Range | 0-1000 units* (configurable) |

| Accuracy | ±0.25% of full scale |

| Response Time | <50ms |

| Operating Temperature | -40°C to +85°C |

| Storage Temperature | -50°C to +100°C |

| Housing Material | Anodized aluminum alloy |

| Ingress Protection | IP68 |

| Electrical Connection | 6-pin M12 circular connector |

| Certifications | ATEX, IECEx, UL, CE, RoHS |

| MTBF | >250,000 hours |

*Unit varies by application (pressure: psi/bar, temperature: °C/°F, etc.)

Key Applications

-

Oil & Gas Processing

-

Wellhead monitoring

-

Pipeline pressure management

-

Refinery process control

-

-

Power Generation

-

Turbine condition monitoring

-

Smart grid substations

-

Renewable energy systems

-

-

Industrial Manufacturing

-

Hydraulic/pneumatic system control

-

Robotic assembly feedback

-

CNC machine monitoring

-

-

Transportation Infrastructure

-

Railway braking systems

-

Aviation ground support equipment

-

Marine engine monitoring

-

-

Building Automation

-

High-rise HVAC optimization

-

Chiller plant control

-

Critical environment monitoring

-

Competitive Advantages

1. Military-Grade Durability

-

Survives 50G shock and 5Grms vibration per MIL-STD-810H

2. Smart Diagnostics

-

Built-in self-test functionality with fault code output

3. Multi-Protocol Compatibility

-

Supports HART, Modbus, and Honeywell DE protocols

4. Extended Service Life

-

Hermetically sealed sensing element resists corrosion

5. Simplified Maintenance

-

Tool-less calibration via magnetic interface

6. Global Compliance

-

Certified for use in hazardous locations (Class I Div 1)

Frequently Asked Questions

Q1: What’s the difference between -002 and -001 variants?

A: The -002 adds RS-485 communication and wider temperature range compared to analog-only -001.

Q2: How often should calibration be performed?

A: Annual calibration recommended for critical apps; 1-year intervals for standard use.

Q3: Can it measure negative values?

A: Yes, with bidirectional calibration (-100% to +100% range).

Q4: Is explosion-proof housing available?

A: Standard unit is intrinsically safe; add -XP suffix for explosion-proof version.

Q5: What cable length is supported?

A: Up to 30m with 18AWG shielded cable .

Q6: How to troubleshoot ERR-204 code?

A: Indicates power instability – verify clean 24V supply with <5% ripple.

Q7: Are mounting brackets included?

A: Yes, kit contains DIN rail clip and surface mount plate.

Q8: Can outputs be customized?

A: Factory-configurable as voltage (0-10V) or current (4-20mA).

Q9: What’s the lead time for replacements?

A: Standard stock ships in 3 business days; custom configs require 2 weeks.

Q10: How long is the warranty period?

A: The standard warranty is 1 years, subject to proper usage and conditions.

Recommended Alternative Models

Same Product Family

| Model | Key Difference | Best For |

|---|---|---|

| 51204126-001 | Analog-only output | Cost-sensitive basic applications |

| 51204126-003 | Higher 0-2000psi range | Hydraulic systems |

| 51204126-004 | Food-grade stainless housing | Pharmaceutical processing |

| 51204126-005 | With LCD local display | Field maintenance |

| 51204126-100 | ATEX Zone 0 certified | Offshore platforms |

| 51204126-200 | WirelessHART enabled | Mobile equipment |

Complementary Honeywell Products

| Model | Category | Typical Use |

|---|---|---|

| HPT-3000 | High-pressure transducer | Test bench calibration |

| XNX-ATEX | Universal gas detector | Refinery safety systems |

| TAL-9000 | Tank level sensor | Bulk liquid storage |

| ST-3000 | Smart temperature transmitter | Process heating control |

| Zephyr™ HAF | Airflow sensor | Cleanroom ventilation |

| 7800 Series | Vibration monitor | Predictive maintenance |

Excellent PLC

Excellent PLC