| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

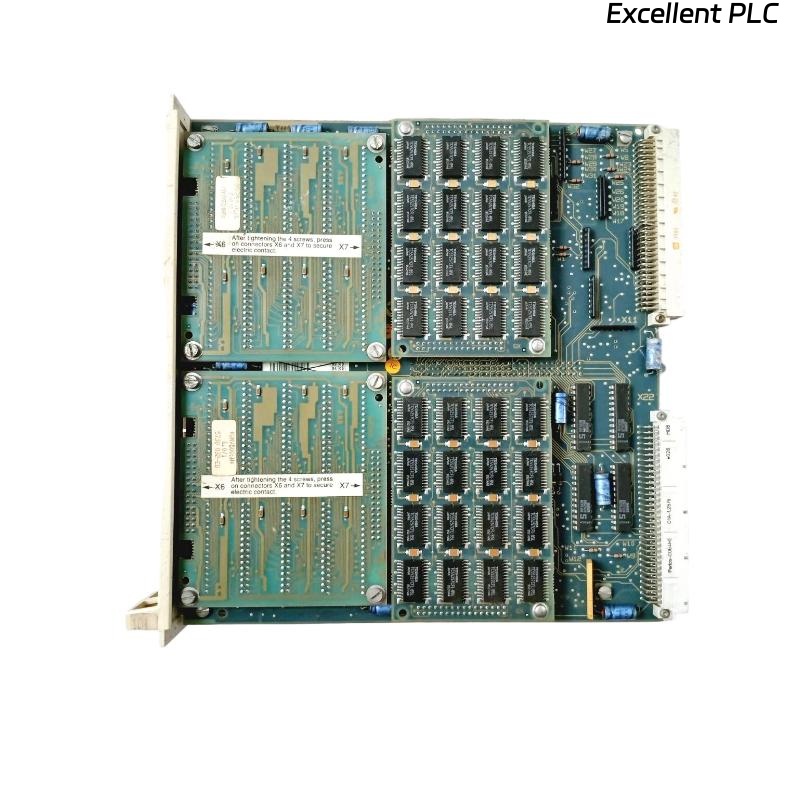

The ABB DSQC 325 is a high-performance I/O module designed for industrial automation and robotics applications. It is part of ABB’s renowned range of control systems, offering reliable signal processing and communication capabilities. This module is widely used in robotic workcells, manufacturing lines, and other automated systems where precise I/O control is essential.

Built with rugged industrial-grade components, the DSQC 325 ensures durability in harsh environments. Its compact design and flexible configuration make it suitable for integration into various automation setups.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | DSQC 325 |

| Input Voltage | 24V DC (±10%) |

| Number of Inputs | 8 digital inputs |

| Number of Outputs | 8 digital outputs |

| Input Type | Sinking/Sourcing (configurable) |

| Output Type | Relay or Transistor (depending on variant) |

| Communication | DeviceNet, Profibus, or Ethernet (varies by model) |

| Dimensions | 124 x 124 x 119 mm |

| Weight | 1.2 kg |

| Operating Temperature | -25°C to +55°C |

| Protection Rating | IP20 |

| Mounting | DIN rail or panel mounting |

Product Applications

The ABB DSQC 325 is widely used in the following industrial scenarios:

-

Robotic Workcells: Provides I/O interfacing for ABB robots, enabling communication between controllers and peripheral devices.

-

Assembly Lines: Facilitates signal processing for sensors, actuators, and other automation components.

-

Material Handling: Used in conveyor systems, sorting machines, and automated storage solutions.

-

Welding & Painting Systems: Ensures precise control in robotic welding and painting applications.

-

Packaging Machinery: Enables high-speed I/O operations in packaging and labeling systems.

Product Advantages

-

High Reliability: Designed for continuous operation in demanding industrial environments.

-

Flexible Configuration: Supports multiple communication protocols (DeviceNet, Profibus, Ethernet).

-

Compact Design: Saves space in control cabinets while offering high I/O density.

-

Easy Integration: Compatible with ABB’s robotic controllers (IRC5, OmniCore) and third-party PLCs.

-

Durable Construction: Resistant to electrical noise, vibrations, and temperature fluctuations.

-

Quick Installation: DIN rail mounting simplifies setup and maintenance.

Frequently Asked Questions (FAQ)

-

What communication protocols does the DSQC 325 support?

Depending on the variant, it may support DeviceNet, Profibus, or Ethernet. -

Can the DSQC 325 be used with non-ABB controllers?

Yes, it can be integrated with third-party PLCs if the communication protocol is compatible. -

What is the maximum load current for the outputs?

Typically 2A per output (varies by model; refer to the datasheet). -

Is the DSQC 325 suitable for outdoor use?

No, it has an IP20 rating and should be installed in a protected enclosure. -

How do I configure the I/O settings?

Configuration is done via ABB’s RobotStudio or a compatible programming tool. -

What is the lifespan of the relay outputs?

Approximately 100,000 cycles under normal operating conditions. -

Can I expand the number of I/O points?

Yes, additional modules can be daisy-chained via the communication bus. -

Does the DSQC 325 support hot-swapping?

No, power must be turned off before installation or removal. -

What is the warranty period for this module?

Typically 12 months, depending on the region and supplier. -

Where can I find the firmware updates?

Firmware updates are available on ABB’s official website or through authorized distributors.

Recommended Related & Popular Models

| Related Models (Same Series) | Description |

|---|---|

| DSQC 328 | 16-input/16-output module with Ethernet |

| DSQC 332 | Analog I/O module for precision control |

| DSQC 345 | High-speed digital I/O with Profibus |

| DSQC 351 | Safety-rated I/O module for robot cells |

| DSQC 378 | Compact I/O with DeviceNet support |

| DSQC 1000 | Advanced I/O for OmniCore controllers |

| Popular ABB Models (Other Series) | Description |

|---|---|

| IRC5 Robot Controller | ABB’s flagship robotic control system |

| OmniCore C30 | Next-gen robot controller with AI features |

| ACS880 Drive | High-performance industrial drive |

| PM865 PLC | Modular automation controller |

| SafeMove 2 | Safety solution for collaborative robots |

| Yumi IRB 14000 | Dual-arm collaborative robot |

Excellent PLC

Excellent PLC