| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

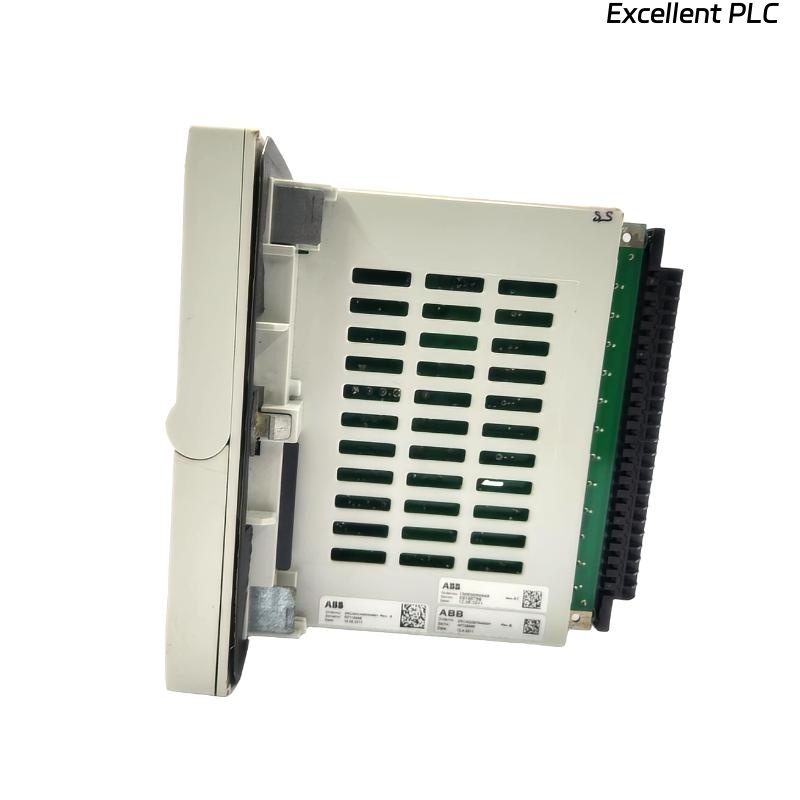

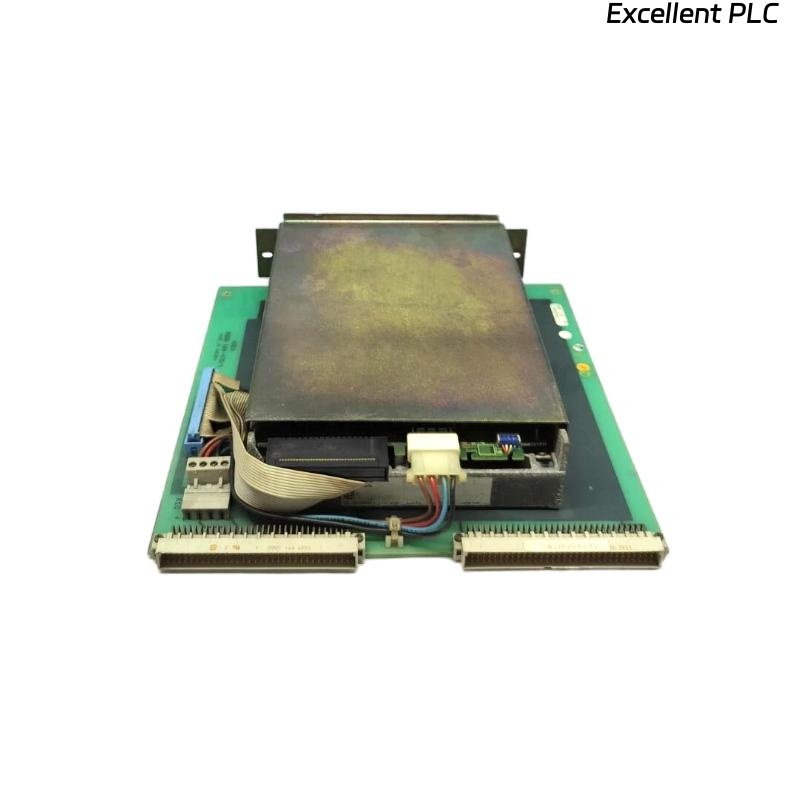

The ABB REM610 is a dedicated motor protection relay designed to provide comprehensive protection, supervision, and control for asynchronous (induction) motors in industrial, utility, and infrastructure applications. As a member of the Relion® 610 series, the REM610 is built on proven technology that ensures dependable motor operation, efficient energy use, and system reliability.

This relay supports low- and medium-voltage motors and offers reliable protection against thermal overload, phase failures, locked rotor, unbalance, and short circuits. It integrates seamlessly with various control and monitoring systems, offering flexible installation options and robust communication capabilities through widely accepted industrial protocols.

Product Specifications

| Parameter | Value |

|---|---|

| Model | REM610 |

| Relay Type | Motor Protection Relay |

| Supported Motors | Asynchronous (induction) motors |

| Rated Frequency | 50/60 Hz |

| Rated Current | 1 A / 5 A (configurable CT input) |

| Thermal Overload Protection | Yes (IEC/ANSI curves) |

| Phase Unbalance Protection | Yes |

| Locked Rotor Protection | Yes |

| Stator Earth Fault Protection | Yes |

| Phase Reversal Detection | Yes |

| Trip and Control Outputs | 4 Binary outputs (programmable) |

| Binary Inputs | 6 Digital inputs (programmable) |

| Voltage Inputs | Optional |

| User Interface | Graphical LCD display, LEDs, keypad |

| Communication Protocols | IEC 60870-5-103, Modbus, optional IEC 61850 |

| Data Logging | 1000 events, 16 fault records |

| Disturbance Recorder | Integrated, up to 32 samples per cycle |

| Mounting | Panel or flush mounting |

| Configuration Software | PCM600 |

| Ingress Protection | IP54 (front), IP20 (rear) |

| Operating Temperature | –25°C to +55°C |

| Storage Temperature | –40°C to +70°C |

| Dimensions (H × W × D) | 177 × 177 × 149.3 mm |

| Weight | 3.5 kg |

| Standards Compliance | IEC 60255, CE, RoHS, UL |

Product Applications

The ABB REM610 is engineered for the protection and monitoring of motors in a wide range of industrial and utility environments, including:

-

Water and wastewater treatment plants

-

Oil and gas facilities

-

Mining and metals operations

-

Pulp and paper industries

-

HVAC and building services

-

Power generation plants

-

Chemical and pharmaceutical industries

-

Material handling systems and conveyor lines

Product Advantages

-

Complete Motor Protection

Offers comprehensive motor protection functions including overload, short circuit, locked rotor, and phase reversal to maximize motor life and reduce downtime. -

High Customization with Logic Programming

Internal logic configurable via PCM600, enabling custom tripping and alarming sequences to match operational requirements. -

Easy Commissioning and Diagnostics

Intuitive local HMI with graphical display and event logs simplifies field operation, fault investigation, and setup. -

Advanced Fault Recording

Built-in disturbance recorder and time-stamped event history improve post-fault diagnostics and root cause analysis. -

Communication-Ready

Compatible with a wide range of industrial protocols (Modbus, IEC 60870-5-103, and optional IEC 61850), supporting digital substations and centralized SCADA systems. -

Rugged and Reliable

Designed to withstand harsh industrial conditions with robust EMC performance and wide temperature operating range. -

Compact Form Factor

Saves panel space and fits into both new installations and retrofitting projects. -

Global Standards Compliance

Adheres to international standards, ensuring compatibility with global projects and ease of certification.

Frequently Asked Questions

-

Can the REM610 perform thermal overload protection based on IEC curves?

Yes, the relay provides thermal overload protection using configurable IEC or ANSI curves to match motor characteristics. -

Does the REM610 detect locked rotor conditions during startup?

Yes, it includes locked rotor detection using time-current characteristics during motor start-up. -

How does the REM610 differentiate between motor start-up inrush and actual faults?

It uses a built-in start-up supervision logic with configurable time delays to ignore normal inrush currents. -

Can REM610 monitor motor start time and number of starts?

Yes, it tracks cumulative start times and restricts the number of starts per hour to prevent overheating. -

Is phase reversal detection available?

Yes, the relay can detect incorrect phase sequence and block motor start accordingly. -

Can I use REM610 with both 1 A and 5 A CTs?

Yes, it supports selectable current inputs via configuration for both 1 A and 5 A CTs. -

Is the REM610 suitable for motors started via soft starters or VFDs?

Yes, it can be used with DOL, soft starters, or VFDs, though protections must be adjusted accordingly. -

Can REM610 interface with a SCADA system using IEC 61850?

Yes, some models support IEC 61850 for full SCADA and substation automation integration. -

What fault records does REM610 store?

It stores up to 16 fault records including fault type, duration, current values, and time stamps. -

Does the relay support event tagging with real-time clock?

Yes, events and faults are time-stamped using the relay’s internal clock, which can be synchronized via communication protocols.

Related Models from the Same Series

| Model | Function | Key Features | Typical Application |

|---|---|---|---|

| REM601 | Basic motor protection | Compact design, basic protection | Small industrial motors |

| REM615 | Advanced motor protection | RTD inputs, IEC 61850, diagnostics | Medium to large motors |

| REM620 | Multifunctional motor protection | Multi-protocol, load shedding | Process industry motors |

| REM630 | High-end motor protection | Redundant comms, diagnostics | Critical motor drives |

| REJ610 | Feeder/motor protection | Overcurrent + motor protection | Mixed load feeders |

| REX610 | Scalable protection | Modular platform for motors & feeders | Multi-load substations |

Popular ABB Models (Same Brand)

| Model | Type | Main Features | Primary Use |

|---|---|---|---|

| REF615 | Feeder Protection Relay | Arc detection, directional OC | Medium-voltage feeders |

| RET615 | Transformer Protection Relay | Differential + REF, IEC 61850 | Power transformers |

| REL650 | Distance Protection Relay | Line distance, autoreclosing | Transmission lines |

| REX640 | Universal Protection & Control | Modular, multi-function, scalable | Digital substations |

| REF620 | Feeder Protection | Advanced logic, fault isolation | Industrial switchgear |

| REJ603 | Ground Fault Protection Relay | Compact, IEC 61850, SCADA integration | RMUs and distribution feeders |

Excellent PLC

Excellent PLC